Advanced

Advanced custom CNC machining is a technology that allows for personalized design and production based on specific customer needs. It not only provides high-precision parts, but also optimizes production efficiency and quality control. Specifically, this process uses computer programming to control machine tools for automated processing, greatly improving production efficiency and processing accuracy. In addition, advanced customization also means that each part is tailored to the customer's needs, ensuring that the final product perfectly meets the customer's usage requirements.

Advanced customization

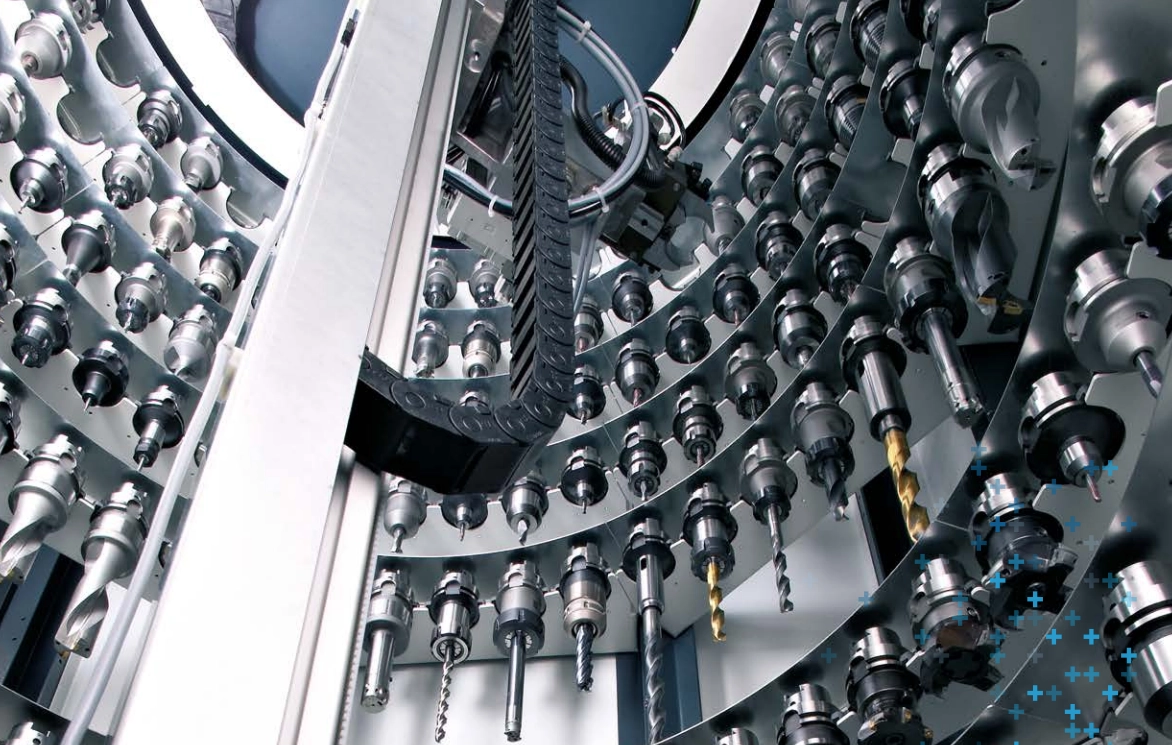

High degree of automation

:Advanced custom CNC processing technology uses advanced CNC machine tools and realizes fully automated production through computer programming. This not only reduces the errors caused by manual operation, but also greatly improves production efficiency. Compared with traditional machine tools, CNC machine tools can run continuously without frequent shutdown adjustments, thus shortening the production cycle.

High precision

:Since CNC machine tools use computers to precisely control the tool movement trajectory, their processing accuracy is much higher than that of traditional machine tools. Advanced custom CNC machining can control the processing accuracy to the micron level or even higher, which is especially important for parts that require high precision. For example, in the aerospace field, the accuracy of parts directly affects flight safety and performance.

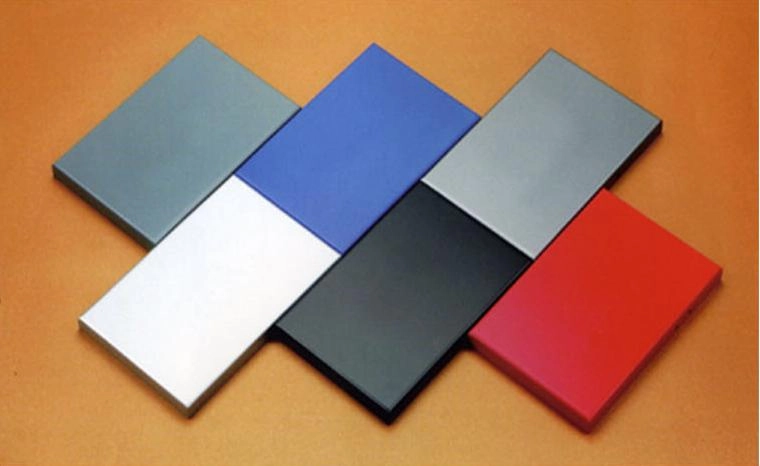

Diverse material applicability

:Advanced custom CNC machining technology is suitable for a variety of materials, including metal, plastic, wood, glass, foam and composite materials. Whether it is hard alloy or soft rubber, it can be accurately processed by CNC machine tools. This wide applicability enables advanced custom CNC machining to meet the special needs of different industries and fields.

Strong flexibility

:Advanced custom CNC machining technology is extremely flexible and can quickly adjust the production process according to the different needs of customers. Whether it is small batch production or large-scale production, CNC machine tools can easily cope with it. Especially in the trial production stage of new products, CNC machining can quickly provide samples and help companies shorten the R&D cycle.

Cost-effective

:Although the initial investment of advanced customized CNC machining is large, due to its high efficiency and high precision, it can save a lot of costs in the long run. First, reducing manual operations means reducing labor costs; second, improving machining efficiency means shortening production time, thereby reducing energy consumption and equipment wear; finally, high-precision machining reduces scrap rate and improves material utilization. All these make advanced customized CNC machining highly cost-effective.

Hitting the pain points

Traditional CNC processing models often fail to balance efficiency and personalization, resulting in serious product homogeneity and difficulty in meeting the diverse needs of customers. Advanced customized CNC processing services accurately match customer needs. It not only provides fast response and efficient production, but also integrates customer personality elements into the design and manufacturing process to achieve true tailor-made. In this model, whether it is small-batch production or prototyping, the most optimized solution can be obtained, effectively solving the market's urgent demand for differentiated and customized products.

Features

1. Flexible design capabilities

The core of advanced custom CNC machining lies in its powerful design flexibility. Through advanced CAD/CAM software systems, engineers can work closely with customers to transform complex design concepts into precise machining instructions. This process is not limited to the conversion of two-dimensional drawings, but also covers advanced functions such as three-dimensional modeling and simulation analysis. Details determine success or failure to ensure that the design is both beautiful and practical.

2. Precision machining technology

Using high-precision CNC machine tools and multi-axis linkage technology, advanced custom CNC processing can process materials with various complex geometric shapes, such as titanium alloys, composite materials, etc., to ensure that the product dimensional accuracy and surface finish reach the micron level standard. In addition, the use of auxiliary processes such as laser cutting and EDM further improves the processing quality and efficiency.

3. Material diversity support

For different application scenarios, advanced custom CNC machining can use a variety of high-performance materials, including but not limited to metals (aluminum, steel, copper), non-metals (plastics, wood) and special composite materials. This provides customers with a wider range of choices to meet the needs of use in specific environments.

4. One-stop service experience

From project consultation, scheme design, sample production to mass production, advanced custom CNC machining provides full-process services. The professional project management team is responsible for coordinating all aspects to ensure that the project is delivered on time, while reducing communication costs and improving overall efficiency.