Aerospace

CNC machining and Aerospace

Stable accuracy

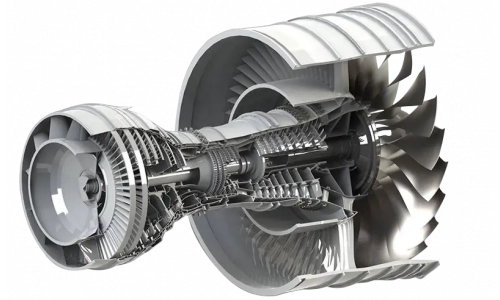

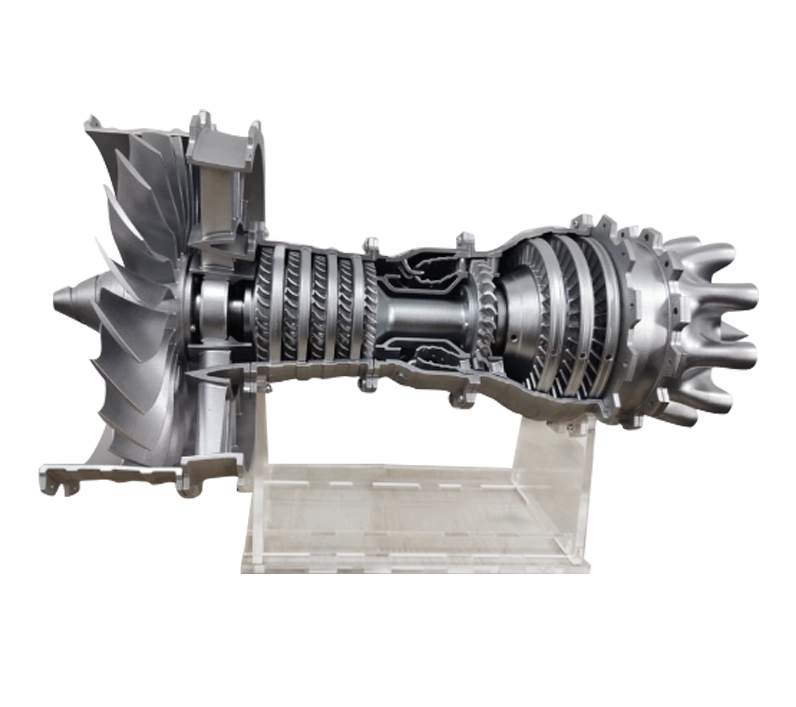

In modern Aerospace manufacturing, every tiny component plays a vital role. These components must not only have extremely high precision, stability and consistency, but also be able to withstand extreme conditions. It is this pursuit of perfection that promotes the widespread application of CNC machining technology in the aerospace field. As a professional industrial engineer, I know how this technology can change the production process of aircraft parts and raise the standards of the entire industry.

Imagine that when an airplane soars in the sky, there are countless precision engineering achievements hidden behind it. CNC processing technology is one of the keys to achieving these results. It uses high-precision CNC machine tools to manufacture various complex parts, ensuring that each component can meet the design specifications and meet the strict quality requirements of the aerospace industry.

Linked processing

In the case of Aerospace, we can see the strong influence of CNC machining technology. The company uses the latest five-axis linkage CNC milling machine for processing operations, which not only greatly improves production efficiency, but also significantly reduces production costs. For example, when producing a certain model of engine blades, traditional manual grinding takes several days to complete a sample. However, using CNC technology, the same workload can be completed in just a few hours, with higher precision and better repeatability. good.

In addition to improving efficiency, CNC machining technology can also help designers achieve more bold and innovative designs. Without the constraints of traditional molds, engineers are free to explore more complex and better-performing designs, thereby promoting technological progress throughout the industry. For example, in the process of manufacturing new composite structural parts, CNC technology makes geometric shapes that were originally difficult to achieve within reach, greatly expanding the application range of materials.

Feature

High precision:

CNC machining technology can process with micron-level precision to ensure that every part meets the design requirements. This is crucial in the aerospace industry, where any small error can have serious consequences.

High efficiency:

By controlling the movement trajectory and processing parameters of the machine tool through computer programming, CNC processing technology can realize automated production and greatly improve production efficiency. At the same time, because human intervention is reduced, the possibility of errors is also reduced.

High flexibility:

CNC machining technology can be programmed and adjusted according to different processing needs, and is suitable for processing parts of various complex shapes. This makes its application in the aerospace field more extensive and flexible.

Good quality consistency:

Since CNC machining technology is automated production, the processing process of each part is the same, thus ensuring product quality and consistency. This is especially important in the aerospace industry, where every part must meet strict standards.

Opportunity

CNC machining technology continues to promote innovation and development in the aerospace industry. With the advancement of science and technology and the expansion of application fields, CNC processing technology is constantly updated and improved. For example, new technologies such as multi-axis linkage CNC machining technology and high-speed and high-precision CNC machining technology that have emerged in recent years are bringing more possibilities and opportunities to the aerospace field.