New Energy

New energy and CNC

In the wave of new energy revolution, CNC processing technology has become a key factor in promoting the development of new energy equipment with its unique advantages. This high-precision manufacturing method not only ensures the efficient operation of new energy equipment, but also greatly improves the performance and service life of the product.

CNC machining (Computer Numerical Control) is an automated machine tool processing process controlled by a computer program. It allows extremely precise machining and is suitable for the production of complex-shaped parts. In the field of new energy, the importance of this technology is particularly prominent because it is directly related to energy conversion efficiency and equipment stability. In wind turbines, for example, turbine blades need to be designed to capture maximum wind energy while also withstanding the stresses of extreme weather conditions. CNC machining technology can produce blades that meet strict tolerance requirements, ensuring that their aerodynamic characteristics are accurately achieved.

Likewise, CNC machining is used to cut and shape silicon wafers during the production of solar panels. These silicon wafers are the core part of solar cells, and their quality directly affects the photoelectric conversion efficiency of the cells. By using CNC technology, manufacturers are able to ensure consistent quality and precision on every wafer, thereby improving the performance of the entire solar panel.

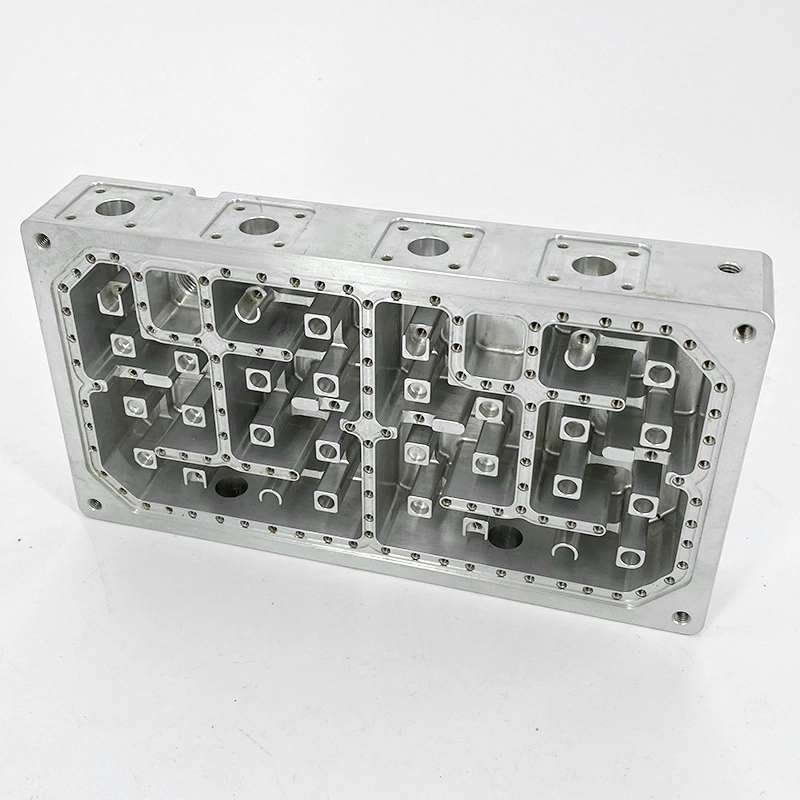

In addition, with the rapid development of the new energy vehicle market, battery performance requirements are becoming higher and higher. CNC machining plays an important role here, and it can be used to manufacture precision metal parts of batteries, such as battery cases and connectors. These components must have high strength and good electrical conductivity to ensure the safety and reliability of the battery. The high precision and repeatability provided by CNC machining ensures that each component meets strict standards, thereby providing a more stable and durable power source for electric vehicles.

In short, CNC processing technology plays an indispensable role in the new energy revolution. It not only improves the production efficiency of new energy products, but also ensures the high quality standards of the products. With the continuous advancement of technology and the expansion of application scope, we can foresee that in the future new energy field, CNC machining will continue to play a key role in helping mankind achieve greener and sustainable development goals.

Application

CNC machining technology is increasingly used in the field of new energy, especially in the production and manufacturing of wind turbines and solar panels, where it plays a vital role. In the manufacturing process of wind turbines, CNC technology is used to accurately machine large blades, hubs and other key components. These components require extremely high precision because they directly affect the stability and efficiency of the wind turbine. With CNC machining, manufacturers are able to guarantee that the size and shape of each component exactly conforms to design specifications, ensuring high performance and long life of the final product.

The production of solar panels also relies on CNC machining technology. During the manufacturing process, CNC machines are used to cut silicon wafers, a key component of solar panels. High-precision CNC cutting maximizes material utilization and reduces waste while ensuring dimensional consistency for each silicon wafer. This is crucial to improving the photoelectric conversion efficiency of solar panels. In addition, CNC technology is also used to process various components of solar trackers. These trackers can adjust the angle of the solar panels according to the position of the sun to achieve the best light reception effect and further improve energy conversion efficiency.

To sum up, CNC processing technology plays an indispensable role in the production of new energy equipment. Whether in the large-scale component manufacturing of wind turbines or the fine processing of solar panels, CNC technology has demonstrated its advantages of efficiency and precision. With the continuous advancement of new energy technology and the growth of market demand, CNC processing technology will continue to play a core role in this field, promoting the innovation and development of new energy equipment, and assisting the transformation and upgrading of the global energy structure.

Performance and efficiency

CNC machining technology plays an indispensable role in the manufacturing process of new energy products with its excellent precise control capabilities. This technology enables precise operation of machine tools through computer programming, ensuring that every component reaches extremely high precision standards. For example, in wind turbine blade manufacturing, CNC technology can precisely cut and shape composite materials to accommodate complex aerodynamic design requirements. This high precision not only reduces material waste but also improves the aerodynamic efficiency of the blades, thereby improving the performance of the entire wind power system. Similarly, in the production of solar panels, the application of CNC technology allows the cutting of silicon wafers to be more precise, reducing the gaps between cells and improving photoelectric conversion efficiency.

CNC processing technology not only improves product quality, but also significantly extends the service life of new energy products. Due to its precise machining capabilities, friction and wear between parts can be reduced, reducing maintenance costs and frequency. Taking the power battery of electric vehicles as an example, CNC technology can accurately manufacture battery casings and connectors to ensure the structural stability and good heat dissipation performance of the battery pack, which is crucial to preventing battery overheating and extending battery life. In addition, CNC technology can be used to create efficient cooling system components such as radiators and cooling tubes, which are essential for maintaining batteries and other electronic devices operating at optimal operating temperatures.