Rapid

In today's fast-paced manufacturing environment, companies are facing unprecedented challenges: How to transform ideas into reality in the shortest possible time while ensuring product quality and accuracy? This is exactly what many designers, engineers, and entrepreneurs are thinking about day and night. Imagine what a revolutionary experience it would be if you had a tool that could quickly take your design ideas from drawings to reality!

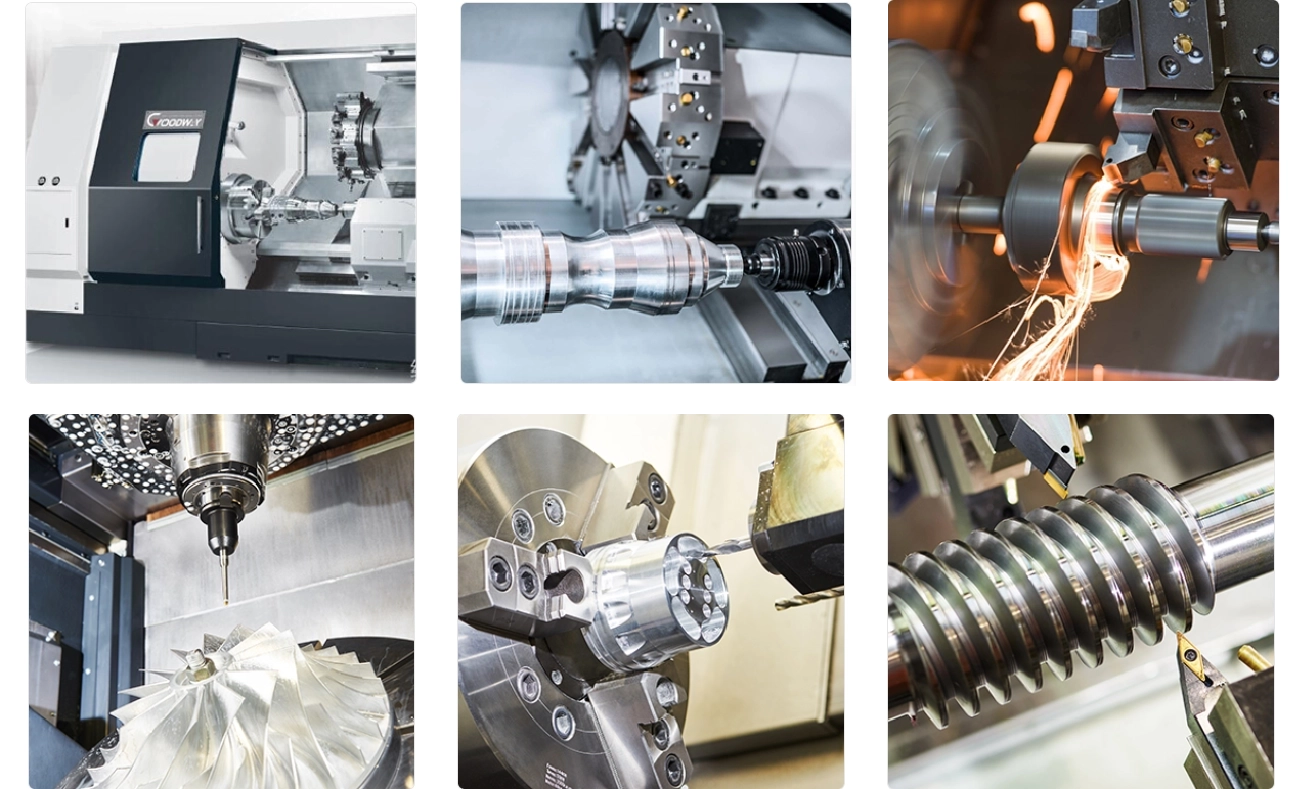

It is based on such market demand that our CNC processing and 3D printing technologies came into being. They are not only production tools, but also accelerators in your innovation journey. Whether it's sophisticated mechanical parts or futuristic design models, we can help you make "rapid prototyping" no longer a dream.

CNC machining: rapid prototyping

CNC (computer numerical control) machining technology has become the cornerstone of modern manufacturing with its unrivaled precision and flexibility. It controls machine tool movement through pre-programmed instructions to achieve high-precision cutting, engraving or shaping of materials. This means that no matter how complex your design is, CNC machining can ensure that every detail is accurately reproduced to meet your ultimate pursuit of quality.

Efficient production

: Compared with traditional manual operations, CNC processing greatly shortens the production cycle and improves work efficiency.

Wide applicability

: Whether it is metal, plastic or wood, CNC processing can easily handle it, broadening the boundaries of design.

Cost effective

: Although the initial equipment investment is relatively high, in the long run, its high efficiency and low error rate can significantly reduce production costs.

3D printing: rapid prototyping

If CNC machining is synonymous with precision, then 3D printing is the releaser of creativity. This technology revolutionizes our understanding of manufacturing, making it possible to “get what you want”. With just a simple 3D model file, the 3D printer can layer materials layer by layer to gradually build a three-dimensional object.

Unlimited design freedom

: 3D printing supports the production of complex geometric shapes without considering the limitations of traditional manufacturing processes.

Iterate quickly

: From design to final product molding, the process is greatly shortened, especially suitable for prototype design and small batch production.

Personalized customization

: Whether it is a unique piece of art or a product that meets personal needs, 3D printing can easily achieve customized production.

Fusion of CNC and 3D printing: the future of innovation is here

Rapid production

Our service features combine these two powerful technologies to provide customers with one-stop solutions. Whether you're a start-up that needs rapid prototyping to validate your design, or an established manufacturer that needs to produce custom parts in low volumes, we have the services to meet your needs. Our team is composed of experienced engineers who are not only technically proficient but also have deep industry knowledge and can provide customers with professional rapid prototyping consulting and support.

Quick AI quote

Using our CNC machining and 3D printing services is easy. Customers only need to provide detailed design drawings or models, and our engineers will work closely with you to ensure that every detail meets your expectations. We use advanced software for design and simulation to ensure the quality and performance of the final product. Once the design plan is confirmed, we can quickly start quotation and production, ensuring high efficiency and high quality whether it is a single prototype or a batch order.

In terms of price, we are committed to providing cost-effective services. We understand the importance of cost control for any project, so we reduce costs by optimizing production processes and technologies while keeping product quality uncompromised. Our goal is to help our customers save time and money without compromising their pursuit of innovation.