Automotive

CNC machining technology, that is, computer numerical control machining technology, has become an indispensable part of modern automobile manufacturing. Through precise programming and operation, CNC machine tools are able to manufacture various complex-shaped automotive parts with extremely high precision. The introduction of this technology not only significantly improves production efficiency, but also greatly improves the quality and consistency of parts. This is undoubtedly a great weapon for automobile manufacturers.

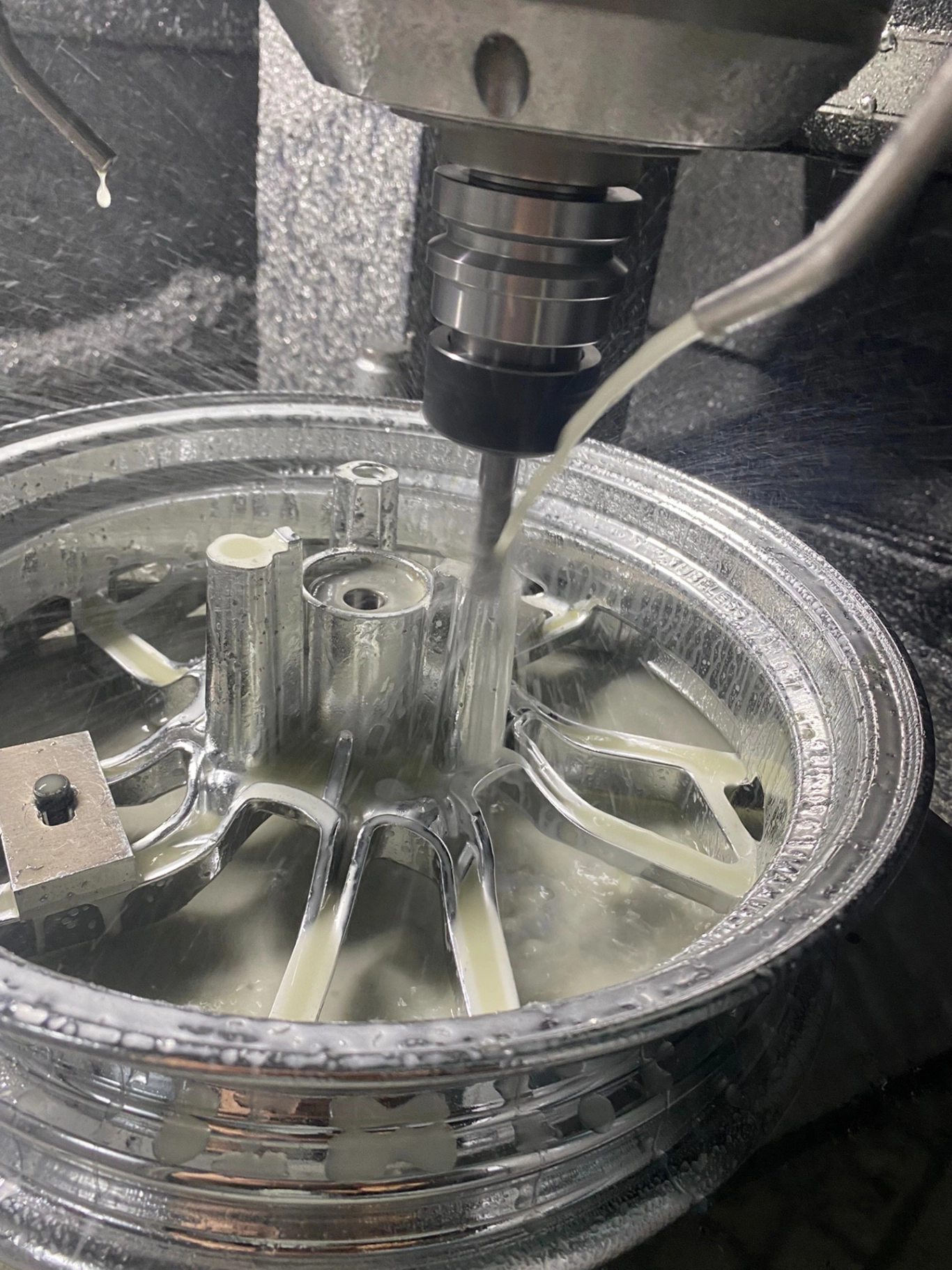

In the traditional automobile manufacturing process, manual operation or semi-automated equipment is often difficult to meet high-precision requirements, resulting in large errors in the size and shape of parts. These errors not only affect the overall performance of the car, but also reduce the safety performance of the vehicle. CNC processing technology has completely changed this situation. By using advanced computer control systems, CNC machine tools can perform high-precision cutting, drilling, milling and other operations according to preset programs, thereby producing parts with precise dimensions and complex shapes. This not only reduces errors during the production process, but also enables each product to meet highly consistent quality standards, providing strong quality assurance for automobile manufacturers.

In addition, the application of CNC processing technology has greatly improved the efficiency of automobile parts production. Compared with traditional production methods, CNC machine tools can complete the production of large quantities of parts in a short time, greatly shortening the production cycle. This means that manufacturers can respond to market demand faster and launch new models in a timely manner, thus taking advantage of the market. At the same time, due to the high-precision characteristics of CNC processing, manufacturers can reduce material waste, further reduce costs, and improve economic benefits.

CNC machining technology has brought revolutionary changes to modern automobile manufacturing industry with its high precision and high efficiency. It not only improves the production quality and efficiency of auto parts, but also promotes the rapid development of the entire industry. In the future, with the continuous advancement of technology and the expansion of applications, CNC processing technology will surely play a more important role in the automotive manufacturing industry and help the automotive industry reach a higher peak.

Perfect blend

In today's automobile manufacturing industry, CNC processing technology has become an indispensable part. This technology accurately controls the movement of machine tools through a computer numerical control (Computer Numerical Control) system to achieve high-precision cutting, drilling, engraving and other operations on various materials, greatly improving the production efficiency and quality of automotive parts. From engine parts to body structure parts to interior decorations, CNC processing runs through almost the entire automobile manufacturing process.

CNC machining improves precision of auto parts

CNC machining technology can achieve micron-level machining accuracy, which is crucial for modern automobiles that pursue ultimate performance and safety. It not only ensures that each part meets strict dimensional standards, but also ensures consistency from batch to batch, thereby reducing errors caused by human factors. For example, when producing turbochargers, even the smallest differences may affect the performance of the final product; with the use of CNC technology, these problems are effectively solved, so that every product shipped from the factory can achieve the best performance. Best condition.

Accelerate the pace of innovation in the automotive industry

As consumer demands become increasingly diverse and market competition intensifies, rapid response to market changes has become the key to the survival and development of automobile companies. CNC machining plays an important role in this process due to its high efficiency and flexibility. Designers can easily modify the design plan through the software and immediately convert it into a physical prototype for testing and verification. This ability to quickly iterate has greatly shortened the time cycle for new models or new technologies from concept to mass production, promoting the speed of innovation and development in the entire industry.

In short, CNC processing is not only one of the important forces driving the current level of automobile manufacturing forward, but also the key to leading future trends. As relevant technologies continue to advance and improve, we have reason to believe that it will continue to bring more surprises to the automotive industry in the future.

Improve accuracy

In the field of modern automobile manufacturing, CNC processing technology has become the key to improving the accuracy of parts. Through the precise control of the computer numerical control system, the machine tool can perform complex and delicate cutting, milling, drilling and other operations to ensure that each component meets the strict requirements of the design specifications. This high-precision production not only reduces the fit errors between parts, but also greatly improves the performance and safety of the entire vehicle. For example, the precision machining of the engine block directly affects fuel efficiency and emission levels, while the accuracy of brake system parts is related to safety performance during emergency braking. Therefore, CNC processing technology is crucial to ensuring the quality of automotive parts.

Furthermore, the introduction of CNC technology has greatly reduced the possibility of human errors, because the entire processing process is controlled by preset programs, avoiding errors that may occur in traditional manual operations. At the same time, it enables highly repeatable batch production, ensuring consistent quality standards for each product. In addition, with the development of multi-axis linkage technology and high-speed cutting technology, CNC machining can now complete more complex three-dimensional shape processing in a shorter time, providing automotive designers with a broader creative space, allowing them to design A new vehicle structure that is both beautiful and practical. These advancements not only drive the pace of innovation in the automotive industry, but also bring more choices and a better driving experience to consumers.

pace of innovation

CNC machining technology has become a key force driving the pace of innovation in the automotive industry. This technology allows designers and engineers to achieve unprecedented design freedom and create new car models that are both beautiful and efficient. By precisely controlling machine tool motion, CNC machining can produce complex-shaped parts that are difficult or cost-prohibitive to achieve with traditional manufacturing methods. For example, streamlined car bodies, complex engine internal structures, and precision cutting of lightweight materials all benefit from the high precision and flexibility of CNC technology.

With the development of CNC technology, the innovation cycle of the automobile manufacturing industry has also been significantly shortened. Businesses are able to move from the concept stage to prototyping to final product production more quickly. This accelerated R&D process not only improves market response but also enhances the competitiveness of the company. More importantly, it brings more choices and a better driving experience to consumers.

In addition, CNC processing technology continues to promote the advancement of materials science. With the ability to process various types of materials, including some emerging high-performance composites, CNC machining is helping automakers explore lighter, stronger and more environmentally friendly material solutions. The application of these new materials can not only further improve vehicle performance, but also reduce energy consumption and emissions, in line with the global trend of sustainable development.

In short, CNC processing technology is not only an important part of modern automobile manufacturing, but also a powerful engine that drives the industry forward. It has greatly accelerated the pace of innovation in the automotive industry and laid a solid foundation for future automotive development by improving design and production flexibility, shortening product time to market, and promoting material innovation.

Economic benefits

The economic benefits of CNC machining technology in automobile manufacturing are significant. It brings cost savings and production efficiency improvements to manufacturers in a variety of ways. Using CNC processing technology can significantly reduce material waste. Because CNC machines can accurately execute cutting paths, almost no excess material is left behind, which directly reduces the cost of raw material usage. In addition, CNC machine tools are usually equipped with automatic tool changing systems and rapid movement functions, which greatly shorten the time to switch from one process to another, thus speeding up production and improving overall efficiency.

The high-precision nature of CNC machining technology also means less rework and lower scrap rates. In traditional manufacturing processes, it is common for parts to fail due to tool or operator errors, which not only adds additional production costs but also delays product time to market. CNC machine tools eliminate this problem through their high consistency and repeatability, ensuring that every part meets strict quality standards, further reducing additional expenses caused by quality issues.

As market competition becomes increasingly fierce, automakers are facing constant pressure to reduce costs. In this context, the use of CNC machining technology to achieve lean production has become particularly important. For example, some advanced automobile companies have integrated CNC into automated production lines, forming a flexible and efficient manufacturing system that can complete the production of customized products in the shortest time. This model not only improves the ability to respond to market demand, but also saves companies a lot of human resources and management costs. In short, the application of CNC processing technology plays an important role in improving the economic benefits of automobile parts manufacturing.

connection technology

In today's automobile manufacturing industry, CNC (computer numerical control) processing technology has become the key to improving production efficiency and product quality. This technology achieves high precision in the production of automotive parts by precisely controlling tool movement and machining processes, greatly reducing errors. This not only directly improves car performance, but also ensures driving safety. For example, precision machining of engine components ensures better fuel efficiency and lower emissions, while precise manufacturing of chassis components improves vehicle stability and responsiveness.

As competition in the automotive industry becomes increasingly fierce, the application of CNC processing technology has accelerated the pace of innovation in the industry. It gives designers the freedom to explore more complex vehicle designs and develop new components that would be nearly impossible with traditional machining techniques. This technological advancement shortens the time from concept to market for cars, promotes rapid iteration of new products, and satisfies consumers' pursuit of freshness and personalization.

The adoption of CNC machining technology also brings significant economic benefits. By reducing material waste, optimizing production processes, and shortening production cycles, manufacturers can effectively reduce production costs. These cost savings can be used for further product innovation or improving customer service quality, thereby enhancing brand competitiveness. In addition, because CNC processing can ensure product consistency and high quality, it reduces the need for after-sales maintenance, which also saves companies a lot of long-term operating costs.

case study

In the automotive industry, CNC processing technology has become an important tool to improve product quality and production efficiency. A typical case is the German car manufacturer BMW. BMW uses CNC machining technology extensively in its engine component manufacturing process, especially in the production of its high-performance engines. By using advanced CNC machine tools, BMW is able to achieve extremely high-precision machining of parts, ensuring efficient engine operation and excellent performance. For example, the crankshaft in BMW's M series engines uses CNC machining technology for precision manufacturing, which not only improves the wear resistance and reliability of the parts, but also significantly improves production efficiency.

In addition, Japanese luxury car brand Lexus also uses CNC processing technology extensively in its vehicle production. Lexus uses CNC machining to manufacture complex engine parts and interior components in the production of its flagship LS model. This highly precise processing technology not only improves product consistency and quality, but also greatly shortens the production cycle, allowing Lexus to deliver high-quality automotive products in a shorter time. Through these successful cases, it can be seen that CNC processing technology plays an important role in improving the accuracy of automotive parts, optimizing the production process, and improving overall production efficiency.

future outlook

The future development prospects of CNC machining technology are undoubtedly broad. With the continuous advancement of artificial intelligence, Internet of Things and big data technology, CNC technology will also usher in new changes. For example, smart manufacturing systems can optimize processing processes through real-time data analysis, improving production efficiency and product quality. At the same time, the integration of additive manufacturing and subtractive manufacturing will make CNC technology more convenient in the production of complex-shaped parts. In addition, the application of new materials and new processes will further expand the application fields of CNC technology. For example, the use of carbon fiber composite materials will make automotive parts lighter, stronger, and more durable.

These technological innovations and application expansion have a profound impact on the automotive industry. First of all, the application of intelligent manufacturing systems will significantly improve the automation level and flexibility of automobile production, allowing the production line to respond to changes in market demand faster and shorten the development cycle of new cars. Secondly, by combining additive manufacturing and CNC technology, automobile manufacturers can produce more complex and higher-performance parts at a lower cost, thus improving the performance and competitiveness of the entire vehicle. Furthermore, the application of new materials can not only reduce the weight of the vehicle body and improve fuel efficiency, but also enhance the safety and durability of the vehicle to meet consumer demand for high-quality cars.