CNC Turning

In modern manufacturing, CNC turning technology has become an indispensable processing method with its high precision, high efficiency and high flexibility. Whether it is mass production or customized production, CNC turning can provide excellent performance and quality. So, what is CNC turning? What is unique about it? CNCKesu will give you a comprehensive explanation of the advantages and application scenarios of CNC turning.

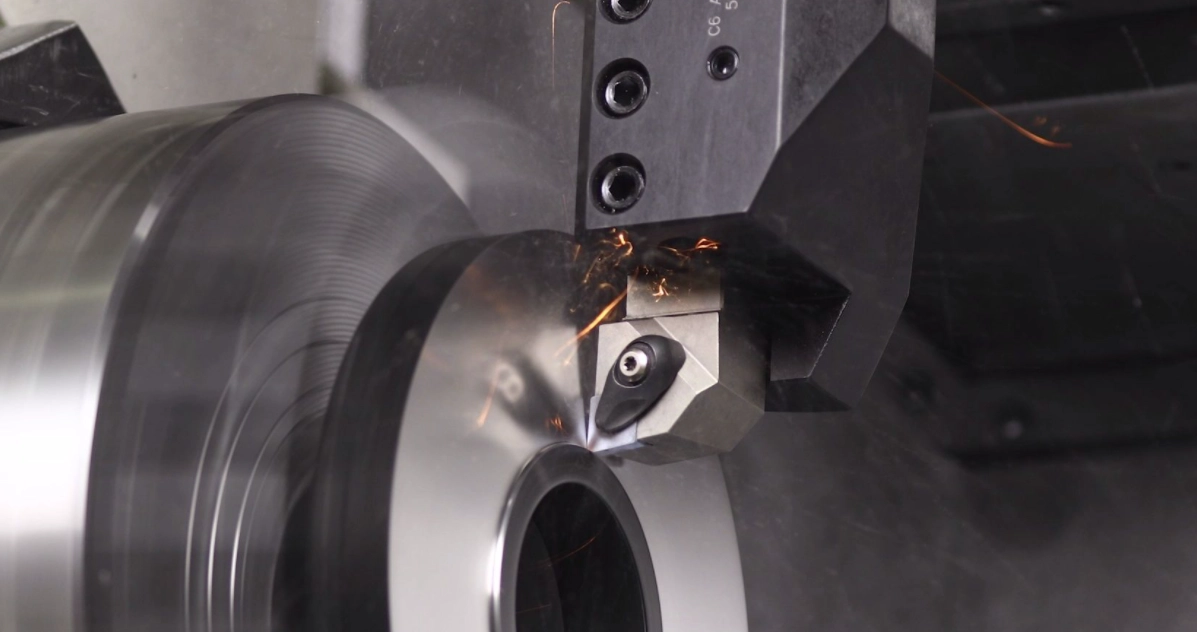

Definition and Principle of CNC Turning

CNC turning refers to the process of cutting materials by controlling the lathe through the Computer Numerical Control (CNC) system. Compared with traditional turning, CNC turning is highly automated and precise, and can complete complex processing tasks according to preset program instructions. Its main working principle is: the operator writes or inputs the processing program on the computer, and then the control system analyzes these programs and drives the various parts of the machine tool to run according to the established trajectory and speed, thereby achieving accurate material removal.

The core advantages of CNC turning

1. High precision and consistency

One of the biggest advantages of CNC turning is that its machining accuracy is as high as micron level, with good repeatability and almost no influence from human factors. This is because the whole process is controlled by computer, avoiding the errors caused by manual operation. For key parts that require strict tolerance matching, CNC turning is undoubtedly the best choice.

2. Efficient production

CNC turning can achieve continuous and uninterrupted work, greatly shortening the production cycle. Especially in mass production, its efficiency advantage is more obvious. In addition, due to the reduction of manual intervention, labor intensity and cost are also reduced.

3. Strong flexibility

CNC turning can easily cope with the processing requirements of various complex shapes and structures, and can quickly switch to new production tasks by simply modifying the program. This flexibility makes it excel in new product trial production and small batch multi-variety production.

4. Good surface quality

Thanks to advanced tool technology and stable cutting conditions, CNC turning can achieve high-quality product surface finish, which is essential for many applications with high requirements on appearance.

Main application areas of CNC turning

1. Aerospace

In the aerospace field, parts often have complex geometries and extremely high precision requirements. CNC turning can meet these stringent standards to ensure the safety and reliability of aircraft.

2. Automobile Manufacturing

The automotive industry is highly competitive and has a high pursuit of production efficiency and product quality. CNC turning not only improves production efficiency, but also ensures the quality of parts, helping manufacturers maintain a competitive advantage in the market.

3. Medical devices

The medical device industry has extremely high requirements for product precision and hygiene. CNC turning can perform precision machining in a dust-free environment to ensure that the product meets strict medical standards.

4. Precision instruments

Precision instruments such as optical devices and sensors require extremely precise components to ensure overall performance. CNC turning provides the necessary accuracy and stability, making it an ideal choice for manufacturing such products.

How to choose the right CNC turning solution for you

Choosing the right CNC turning service provider is crucial to ensuring the success of your project. Here are some key factors for your reference:

Technical strength : Find out whether the service provider has advanced equipment and technical team.

Case studies : Check their past work record, especially the success rate of similar projects.

Customer Service : Excellent communication and service support can help throughout the project.

Reasonable price : While cost is an important consideration, quality should not be sacrificed to save money.

Cooperation and Exchange

As a modern manufacturing technology, CNC turning is gradually changing the traditional industrial model. Whether it is to improve production efficiency or improve product quality, it has shown great potential. I hope we can help you better understand the value of CNC turning and find the right partner for your next project. If you have any questions or need further information, please feel free to contact us!