In today's ever -changing era, companies are facing unprecedented competition pressure. How to develop high -quality products at the lowest cost in the shortest time has become a problem that every company needs to solve. The CNC fast prototype and 3D printing technology are the weapon to solve this problem.

The necessity of fast prototype

Short the development cycle

: In fierce market competition, time is money. Traditional product development processes are often too long due to tedious handmade and testing links. CNC and 3D printing technology can greatly shorten the time from design to physical models, allowing enterprises to respond to market demand faster.

Reduce costs

: By reducing labor costs and waste of materials, fast prototype technology helps companies discover and solve problems in the early stages, and avoid high costs in large -scale production in the later period.

Improve product quality

: Using advanced digital control technology, CNC and 3D printing can achieve high -precision processing to ensure that each detail meets expectations. In addition, through repeated iterative optimization design, the quality of the final product can be significantly improved.

The advantages of CNC fast prototype

High flexibility

: Whether it is plastic, metal or wood, CNC machine tools can easily meet the processing needs of various materials. It can also quickly replace different tools and fixtures to adapt to prototype manufacturing of various complex shapes and sizes.

Digital control

: With the help of a precise digital control system, the CNC machine can accurately control the processing process by computer programming, reduce the error caused by artificial operation, and improve production efficiency and consistency.

High -efficiency automation

: The highly automated characteristics of CNC technology make it very suitable for large -scale production and batch customization. Once the program is set, the machine can work continuously, which greatly improves production efficiency.

3D Printing the Unique Charm of Fast Printing Situation

Unlimited design freedom

: Compared with traditional manufacturing methods, 3D printing is almost unlimited by structural complexity. It can create a complex geometric shape that is difficult to achieve in traditional craftsmanship, providing designers with unlimited creative space.

Fast iteration ability

: The rapid molding characteristics of 3D printing technology allows designers to modify and test design solutions many times in a very short period of time until they find the best design solution.

Environmental protection and energy saving

: 3D printing is a manufacturing process of additive. Only the necessary materials are used to reduce waste of resources. At the same time, it can also use recyclable or biodegradable materials to be more green and environmentally friendly.

The combination application of CNC and 3D printing

Complement advantages

: CNC and 3D printing technology have their own advantages. The combination of the two can achieve the best results. For example, you can first print the preliminary model with 3D printed work, and then use CNC for fine processing, thereby taking into account speed and accuracy.

Innovative Design

: Combined with the characteristics of the two technologies, designers can create products with both innovative and practical and beautiful. For example, in the automotive manufacturing industry, you can first print a complex component prototype with 3D, and then use CNC to complete the final refined processing.

Success case sharing

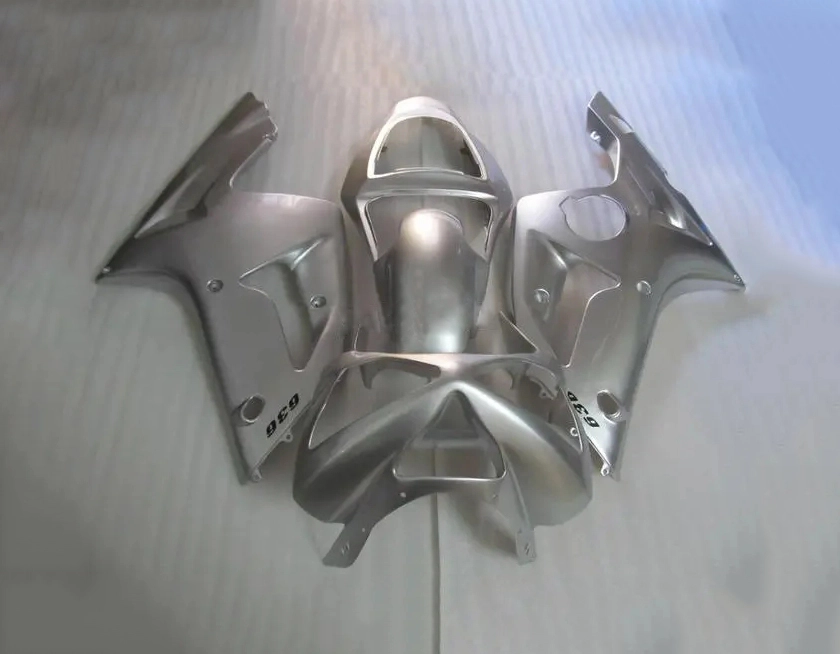

Auto industry

: Many well -known automobile manufacturers have adopted CNC and 3D printing technology in the development of their new models. This not only speeds up the launch of the new car, but also improves the safety and comfort of the vehicle.

Medical fields

: Medical equipment companies use these technologies to produce customized implants and prosthetic limbs, which greatly improves patients' rehabilitation effect and quality of life.

Aerospace

: The aircraft manufacturer uses CNC and 3D printing technology to manufacture complex components, which reduces the weight of the aircraft and improves fuel efficiency.

Purchase and use guidelines

Select the right device

: According to your actual needs and budget, choose a suitable CNC machine tool or 3D printer model. It is recommended to consult professionals to get more information.

Learning operation skills

: Although modern equipment is usually equipped with a user -friendly interface, in order to give full play to its performance, it still needs to master certain operating skills. You can learn by participating in training courses or online tutorials.

Maintenance

: Check and maintain the equipment regularly to keep clean and dry to ensure long -term stable operation. It is necessary to replace the damaged parts in time to avoid affecting normal use.

Price range

: According to different brands and configurations, the price of CNC machine tools ranges from tens of thousands to millions; while 3D printers are relatively cheap, and the entry -level models are more. You can start with a thousand yuan.

Whether it is the CNC fast prototype or 3D printing technology, they are powerful tools to promote the progress of modern manufacturing. If your company is looking for an effective way to improve efficiency and reduce costs, KESU hardware can make your innovation ideas a reality.