Overmolding

Charm

In today's industrial design field, overmolding technology has gradually become an important link in the product design and manufacturing process with its unique charm and excellent expressiveness. The historical background of this technology dates back to the early 20th century, when it was used as an innovative solution to improve the surface quality and durability of products. Over time, overmolding technology continues to advance and improve, and now it has become one of the key means to improve the overall texture and functionality of products.

In industrial design, the appearance and feel of a product often directly affect consumers' purchasing decisions. Overmolding technology covers the base material with a high-performance film or coating to make the product surface smoother and more beautiful, while improving wear resistance and corrosion resistance. The application of this technology not only enhances the visual appeal of the product, but also enhances its practicality and durability, thereby standing out in the fierce market competition.

For example, in the field of electronic products, overmolding technology is widely used in the manufacture of mobile phone casings. By covering the plastic shell with a metal or glass film, you can not only achieve a metallic effect, but also maintain a light weight and excellent heat dissipation performance. This design not only meets consumers' needs for aesthetics, but also ensures the product's stable performance and user experience.

In the automotive industry, overmolding technology also plays an important role. Automotive interior parts such as door panels, dashboards and other components are often covered with soft PVC or other synthetic materials to improve tactile comfort and durability. In addition, overmolding technology is also commonly used in car light housings to enhance light transmittance and impact resistance to ensure driving safety.

Overmolding technology, with its unique advantages, has brought revolutionary changes to product design and manufacturing in various industries. It not only improves the overall texture and functionality of the product, but also creates more market opportunities and competitive advantages for enterprises. With the continuous development and improvement of technology, we have reason to believe that overmolding technology will play a greater role in the future and promote industrial design to a higher level.

Reveal

Overmolding technology, as a force that cannot be underestimated in the field of modern industrial design, its charm comes from its ability to skillfully integrate aesthetics and functionality, giving products a "coat that is both beautiful and practical" ". The history of this technology can be traced back to the mid-20th century. With the advancement of material science and the continuous innovation of manufacturing processes, overmolding has gradually become a key means to improve product quality and enhance user experience. By covering the surface of the basic material with a layer of film or coating with specific properties, it not only gives the product a richer and more diverse appearance and texture, but also significantly improves the product's durability, corrosion resistance, touch and other performance indicators, thus greatly improving the product's performance. Dadi enhances the market competitiveness of its products.

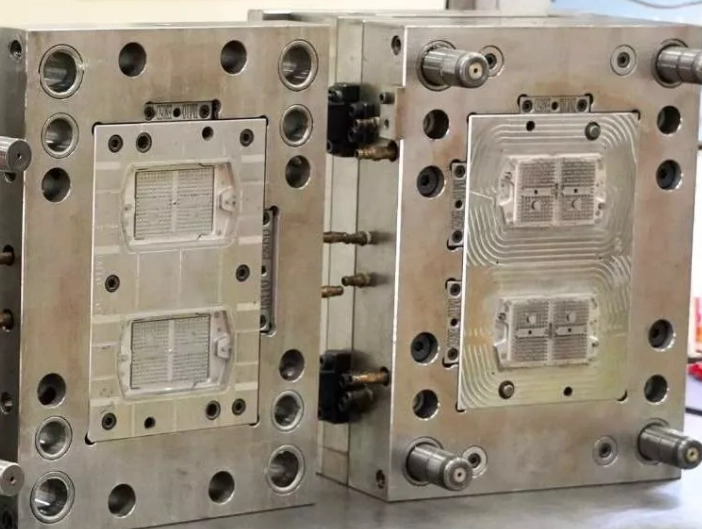

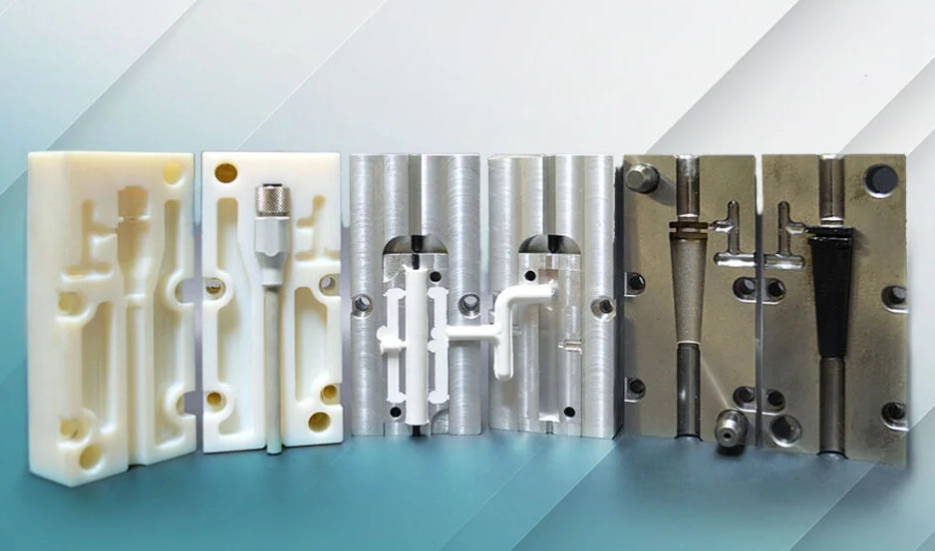

Delving deeply into the technical core of overmolding, we will find that although the process flow is complicated but clear, every step is crucial. The first step is material selection, which tests engineers’ deep understanding and precise grasp of material properties. According to the application requirements of the final product, careful selection of substrates and coating materials that can not only meet the aesthetic requirements but also ensure functional realization is the key to success. Then entering the mold design stage, designers need to fully consider the shape and size of the product as well as various variables in the subsequent molding process to ensure that the mold design is accurate and lay a solid foundation for subsequent processes. The molding process is the climax of the entire technical process. It involves multiple delicate operations such as temperature control and pressure application. Any slight deviation may affect the quality of the final product. Therefore, at this stage, the experience and skills of technical personnel are extremely demanding. They must rely on their rich practical experience and keen judgment to ensure that every detail is optimal.

Share

Overmolding technology has been widely used in different industries due to its unique advantages. Taking electronic products as an example, the casings of many high-end smartphones and tablets use overmolding technology. This process not only gives the product a smooth and delicate surface texture, but also improves its durability and impact resistance. For example, the latest mobile phone of a well-known brand uses an over-molded shell made of polycarbonate and TPU materials, which not only looks stylish, but also has excellent anti-fall and wear-resistant properties. This kind of design not only meets consumers' needs for beauty, but also extends the service life of the product, adding intangible value to the brand.

In the automotive industry, overmolding technology also shines. Automotive interior parts such as instrument panels, door panels and other components are manufactured through this process, which not only improves the overall texture of the car interior, but also enhances the functionality of the components. For example, a new SUV model of a luxury brand uses over-molding technology extensively in the interior, making the interior environment more comfortable and upscale. At the same time, these parts also have good heat resistance and aging resistance, ensuring that the vehicle can still maintain excellent condition during long-term use. The application of this technology has greatly enhanced the brand value and market competitiveness of cars.

Market

Overmolding technology, as an advanced manufacturing process that can significantly improve the appearance, texture and functional performance of products, is gradually gaining favor in the market. In various fields such as consumer electronics, automotive parts, and medical equipment, there is a growing demand for products with better feel, greater durability, and greater visual appeal. This trend not only reflects the upgrade of consumers’ aesthetic and practical needs, but also reflects the desire of enterprises for innovative technologies.

As personalized customization and rapid iteration become the norm in the market, overmolding technology shows great potential for development. It allows designers more flexibility in material selection and surface treatment to create products that both meet functional requirements and have unique aesthetic value. However, the further popularization and application of this technology still faces some challenges, including high equipment investment costs, relatively high technical thresholds, and restrictions in environmental regulations.

For enterprises, if they want to use overmolding technology to enhance product competitiveness, they first need to conduct an in-depth analysis of the consumer demand of the target market and clarify product positioning and differentiation strategies. Secondly, establish a professional R&D team to continuously explore and optimize the overmolding process to improve production efficiency and reduce costs. At the same time, paying attention to the development and application of environmentally friendly materials to meet increasingly stringent environmental standards is also the key to the sustainable development of enterprises. In addition, strengthening cooperation with upstream and downstream industrial chains to form a good industrial ecology can effectively shorten the product development cycle and speed up market response.

The development of overmolding technology brings new opportunities for product design and manufacturing, but it also comes with challenges. Only those companies that can have a keen insight into market changes, continue to innovate and actively respond to environmental protection requirements can stand out in future competition and achieve sustained growth and development.

Innovation

Overmolding technology, as an innovative process method, has shown its unparalleled advantages in many industries. It not only improves the beauty and texture of the product, but also enhances the durability and functionality of the product, making the product more competitive in the market. Through precise material selection and advanced mold design, overmolding technology can achieve perfect reproduction of complex shapes and fine patterns, providing designers with greater room for creativity.

Facing the future, we encourage more companies to adopt overmolding technology as an important tool to improve product quality and enhance market competitiveness. With the continuous advancement of technology and the growing market demand, mastering and applying this technology will be the key to promoting continuous innovation and leading the industry. Let us look forward to working together to create a brighter future through more possibilities and opportunities brought by technological innovation.