Vacuum Casting

Choosing the right vacuum casting factory partner can make all the difference in bringing your product to life. Here's why CNCKesu stands out as an exemplary choice for your manufacturing needs

Experience and Expertise

Proven Track Record

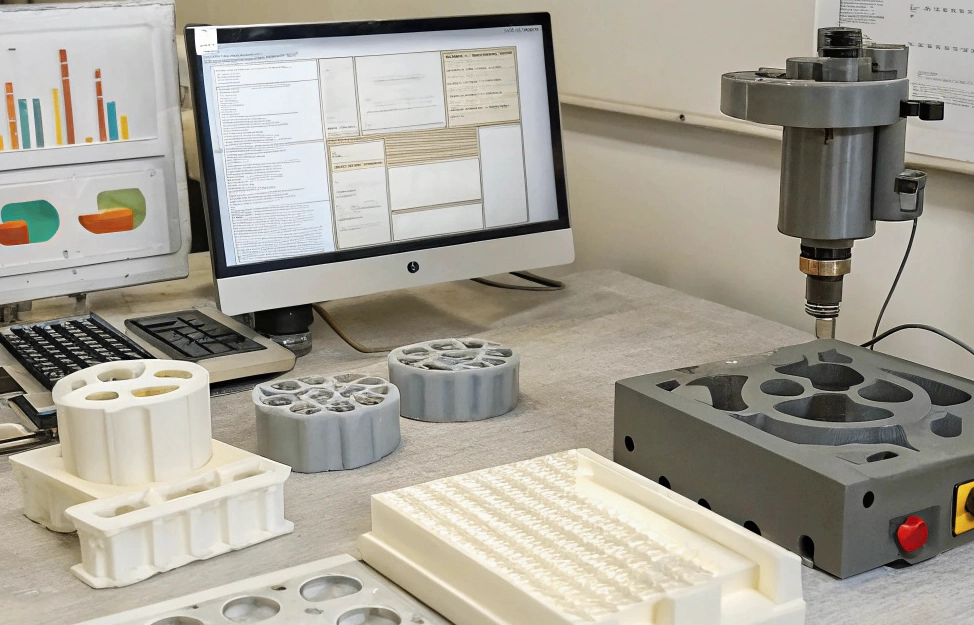

CNCKesu has been at the forefront of vacuum casting for years, delivering top-notch parts to industries ranging from automotive to consumer electronics. Our track record is not just about the number of projects but the quality and reliability of each part produced. This depth of experience means we've navigated through countless challenges, ensuring we can handle whatever your project throws at them.

Skilled Technicians

The team at CNCKesu vacuum casting factory isn't just about following procedures; we're innovators. Our technicians are skilled in traditional vacuum casting techniques while continuously adapting to new technologies. Whether it's improving the casting process for better efficiency or integrating new materials, our expertise ensures your product benefits from the latest advancements in manufacturing.

Quality Assurance

Rigorous Quality Control

From the moment your design hits our floor to the final product leaving it, CNCKesu vacuum casting factory implements stringent quality checks. Each step in the vacuum casting process is meticulously monitored to ensure the parts not only meet but often exceed your expectations. This commitment to quality means fewer defects, better fit, and finish, and ultimately, a product you can trust.

| Vacuum Casting Dimensions (mm) | 0-25 | 25-50 | 50-75 | 75-100 | 100-125 | 125-150 |

| Vacuum Casting Tolerance (mm) | ±0.3 | ±0.35 | ±0.4 | ±0.45 | ±0.5 | ±0.55 |

Certifications

Holding certifications like ISO 9001, CNCKesu demonstrates a commitment to maintaining high-quality standards. These certifications aren't just badges on the wall; we're a testament to CNCKesu's dedication to quality management and continuous improvement in our vacuum casting processes.

Material Versatility

Extensive Material Options

One size doesn't fit all in manufacturing, especially when it comes to materials. CNCKesu vacuum casting factory offers an array of polyurethane resins that can replicate the properties of various plastics, giving you the flexibility to choose what's best for your product. Whether you need something rigid like ABS or flexible like rubber in vacuum casting market, we've got the materials to match.

Custom Material Properties

Beyond just choosing from available options, CNCKesu can customize resin properties to fit your exact needs. Want a specific color, transparency, or hardness? We can tailor the material to ensure your final product not only looks right but also functions as intended.

Customization and Flexibility

Tailored Solutions

Every project is unique, and CNCKesu vacuum casting factory understands this deeply. We provide customized solutions that go beyond materials, tailoring production scales, timelines, and even the process itself to meet your project's demands. Whether you're looking at a small batch for market testing or scaling up for production, we're adaptable in vacuum casting market.

Design Support

Our involvement goes back to the drawing board. CNCKesu offers design support to ensure your product design is optimized for vacuum casting. This foresight can lead to significant cost savings and quality improvements, making your project more viable from the get-go.

Speed and Efficiency

Growth of the Vacuum Casting Market

The vacuum casting market is on an upward trajectory, fueled by the need for rapid prototyping and small-batch production across industries like automotive, aerospace, and healthcare. This method allows for the creation of parts with high precision and material properties akin to those produced through injection molding, but at a fraction of the cost for low volume runs. As businesses increasingly seek agility in product development, vacuum casting's ability to quickly produce functional prototypes and small series without extensive tooling investment continues to drive its market expansion.

Quick Turnaround

In today's fast-paced market, speed can be as crucial as quality. CNCKesu vacuum casting factory prides itself on quick turnovers for prototyping and small batch productions, allowing you to iterate rapidly or launch products faster without sacrificing quality.

Efficient Processes

Efficiency here isn't just about speed; it's about doing more with less. CNCKesu's processes are designed to minimize waste, which not only helps the environment but also keeps costs down, making your project more cost-effective.

Customer Service

Responsive Communication

CNCKesu values clear communication, keeping you in the loop with regular updates on your project's progress. They're quick to respond to queries or changes, ensuring you're never left in the dark.

After-Sales Support

Our service extends beyond delivery. CNCKesu vacuum casting factory provides after-sales support, which might include guidance on assembly, troubleshooting, or just ensuring that you're completely satisfied with the end product.

Cost-Effectiveness

Competitive Pricing

For those looking at small to medium production runs, CNCKesu offers pricing that's competitive, especially when considering the high costs associated with injection molding setups for smaller quantities.

Cost Management

We work closely with you to manage costs, suggesting alternatives in materials or production methods that can help meet your budgetary needs without compromising on the quality or integrity of the product.

Choosing CNCKesu Vacuum Casting factory means you're partnering with a company that brings not just our expertise to the table but also a commitment to quality, flexibility, and customer satisfaction. They're ready to take your project from concept to reality, ensuring it's done efficiently, cost-effectively, and with the highest quality standards in mind.

FAQs

Here are some frequently asked questions about vacuum casting

What are the typical costs associated with vacuum casting?

Costs can vary widely based on part complexity, material choice, and quantity. However, vacuum casting tends to be more cost-effective for small to medium runs than injection molding.

What materials can be used in vacuum casting factory?

Primarily, polyurethane resins are used, which can be formulated to mimic a variety of plastics like ABS, PC, or PP, offering flexibility in terms of hardness, flexibility, and color.

How long does vacuum casting take?

Lead times can range from a few days to a couple of weeks, influenced by the project's complexity, the resin's curing time, and production schedules.