Communication

Communications and CNC machining

The development of communication technology is a magnificent epic. It spans from the early telegraph and telephone, to the discovery and application of radio waves, to today's 5G network and Internet of Things technology. Each step has profoundly changed human life. methods and working modes. In this ongoing revolution, CNC machining technology plays a vital role. It not only greatly improves the efficiency and precision of communication equipment production, but also provides strong technical support for innovation in the communication industry.

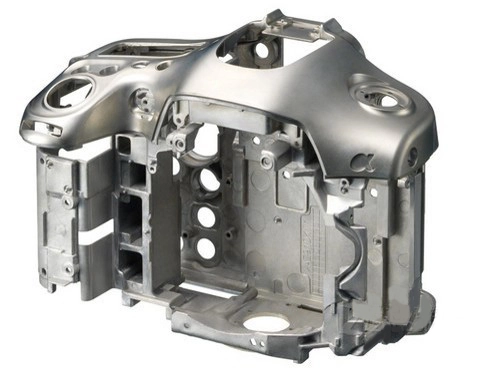

The application of CNC machining technology makes the manufacturing of communication equipment more precise and efficient. When producing key communication components such as base station antennas and precision connectors, CNC machining can ensure that the dimensions of each component are accurate, thereby ensuring the stable operation of the entire system and the quality of signal transmission. In addition, CNC processing has a high degree of automation and can complete the production of large quantities of orders in a short period of time, which is crucial for the rapidly developing communications industry.

With the continuous advancement of communication technology, the requirements for equipment performance are also constantly increasing. CNC machining technology has become a key force in promoting innovation in the communications industry with its excellent processing capabilities and flexibility. It can not only meet the high requirements for precision and reliability of current communication equipment, but also adapt to the development of future communication technology, such as higher frequency signal transmission, smaller size electronic equipment, etc.

The application of CNC machining technology in the communications field is not limited to the production of hardware, but also involves the optimization of product design, the application of new materials, and the improvement of production efficiency. Improvements and innovations in these aspects have jointly promoted the development of the communications industry to a higher level. Therefore, it can be said that CNC machining technology is the accelerator of the revolution in the communications industry. Through continuous technological innovation and application expansion, it has brought unprecedented development opportunities to the communications industry.

Reflect

CNC machining technology, as one of the core technologies of modern manufacturing, has shown its unique value and importance in the field of communication equipment manufacturing. Through high-precision and high-efficiency production methods, CNC machining enables complex and precise communication equipment components to be produced accurately. For example, in the production of base station antennas, CNC machining can ensure the precise angle and size of the antenna, which is crucial to ensuring stable transmission of communication signals. In addition, CNC machining can also provide impeccable precision for small-sized but extremely critical components such as precision connectors, thus ensuring the reliability and efficiency of the entire communication system.

In the production of communication equipment, the application of CNC processing technology not only improves production efficiency, but also significantly reduces production costs. This technology allows manufacturers to mass-produce complex parts at higher speeds and at lower costs, which is critical to meeting the growing market demand for high-performance communications equipment. At the same time, the high flexibility of CNC processing also means that manufacturers can easily respond to changes in product design and quickly adapt to new market demands. This is particularly important for the rapidly developing communications industry, because the technology in this industry is updated very quickly.

The application of CNC processing technology in communication equipment manufacturing not only improves the quality and performance of products, but also speeds up the speed of product launch, winning valuable market opportunities for enterprises. With the continuous advancement and development of communication technology, the importance of CNC processing technology will further increase and become a key force in promoting the continuous innovation and development of the communication equipment manufacturing industry.

Innovation case analysis

In the communication equipment manufacturing industry, CNC processing technology has become an important tool for enterprises to innovate and improve product performance. A typical case is Huawei, which extensively applies CNC technology in the production process of base station antennas. Through high-precision CNC machining, Huawei is able to produce antenna components with a high degree of consistency and precise dimensions, which directly improves the signal transmission efficiency and stability of base stations. In addition, CNC processing also helps Huawei shorten its product development cycle and speed up the market promotion of new products.

Another high-profile case comes from Sweden's Ericsson, a leading global manufacturer of telecommunications equipment. Ericsson uses CNC technology to manufacture precision connectors and other critical communications components. These components require extremely high precision and reliability to ensure seamless operation of the communications system. By using CNC processing, Ericsson not only improved product quality, but also significantly reduced production costs. This cost-effective improvement enables Ericsson to respond more flexibly to changes in market demand and maintain its advantage in fierce global competition.

Fusion trend

With the rapid advancement of science and technology, CNC (computer numerical control) processing technology is standing at the forefront of a new round of industrial revolution, and its future development will undoubtedly have a profound impact on the communications industry. It is expected that CNC technology will further integrate advanced automation and intelligent elements, such as artificial intelligence, machine learning and Internet of Things technology, to improve production efficiency, precision and flexibility. Through the integration of these technologies, CNC machine tools will be able to achieve a higher degree of self-monitoring and self-adjustment, reducing manual intervention, thereby providing greater stability and consistency in the production process.

CNC machining technology is expected to play a greater role in future communication equipment manufacturing. For example, with the development of 5G and subsequent communication technologies, the demand for base station antennas, precision connectors and other key components will become more diverse and complex. The new generation of CNC machine tools can not only meet these high-precision production needs, but also optimize the production process, reduce the scrap rate, and increase production capacity through real-time data processing and analysis. In addition, advances in CNC technology will also make customized production and rapid prototyping possible, which is particularly important to meet the rapidly changing needs of the market.

The development of CNC technology will also promote the communication industry to move towards a higher level of innovation. For example, the application of new materials is one of the important directions in the development of communication technology, and CNC technology can play a key role in this process. By precisely controlling machining parameters, CNC machine tools can achieve fine machining on new materials, thereby developing better-performing communication equipment. In addition, with the development of additive manufacturing technologies such as 3D printing, the combination of CNC processing technology and it will open up more innovative avenues and bring more possibilities to the design of communication equipment.

To sum up, the future trend of CNC machining technology shows that its application in the communication industry will be more extensive and in-depth. By continuously integrating new technologies and innovative concepts, CNC machining will not only improve production efficiency and product quality, but also promote the continuous progress and innovation of communication technology, laying a solid foundation for building a more efficient and smarter communication network.

driving force

Today, as the communications industry continues to reach new heights, CNC machining technology has become an indispensable driving force. It not only improves production efficiency and reduces costs, but also promotes the development of innovative designs, making communication equipment more portable, efficient and reliable. Looking to the future, with the development of 5G and future 6G technology, the requirements for communication equipment will become more stringent, and the continued progress of CNC processing technology will undoubtedly provide strong support to meet these needs.

We have reason to believe that through continuous technological innovation and cross-industry cooperation, CNC machining will play a more important role in the communications field. Whether it is improving the accuracy and performance of existing equipment or developing new application scenarios, CNC machining will become a bridge connecting reality and the future. Therefore, for every participant inside and outside the industry, now is the time to strengthen cooperation and jointly explore the infinite possibilities of CNC technology to jointly create a new era in the communications industry.