5 Axis CNC Machining

5-Axis CNC machining technology

In the wave of modern manufacturing, precision and efficiency have become key indicators for measuring productivity. Faced with increasingly complex parts design and processing requirements, traditional three-axis CNC machine tools are gradually showing limitations and cannot perfectly cope with the challenges of multi-faceted, complex curved surfaces and detailed engraving. This pain point is like a blunt instrument in the hands of a craftsman, limiting the unlimited extension of creativity. As a result, 5-Axis CNC Machining came into being. It not only broke this bottleneck, but also led a new era of precision manufacturing with a revolutionary attitude.

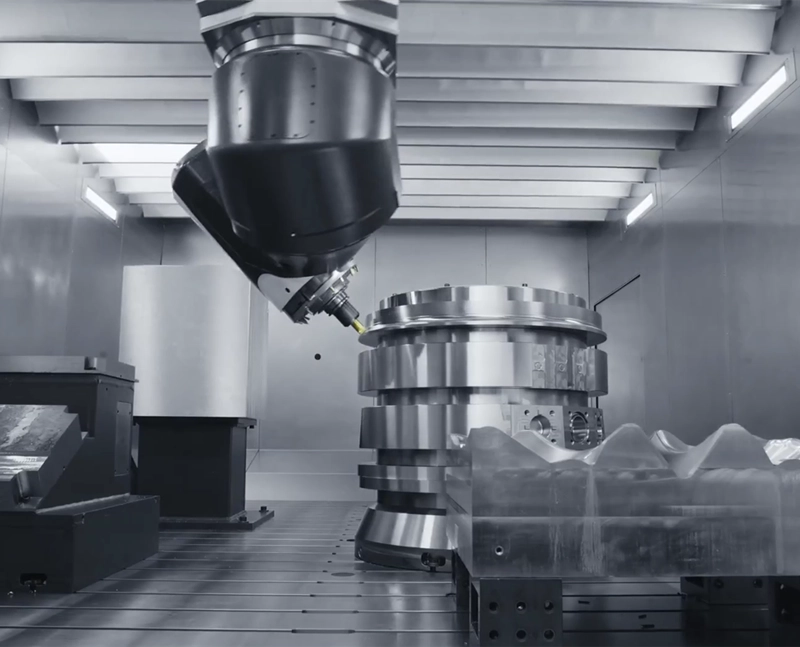

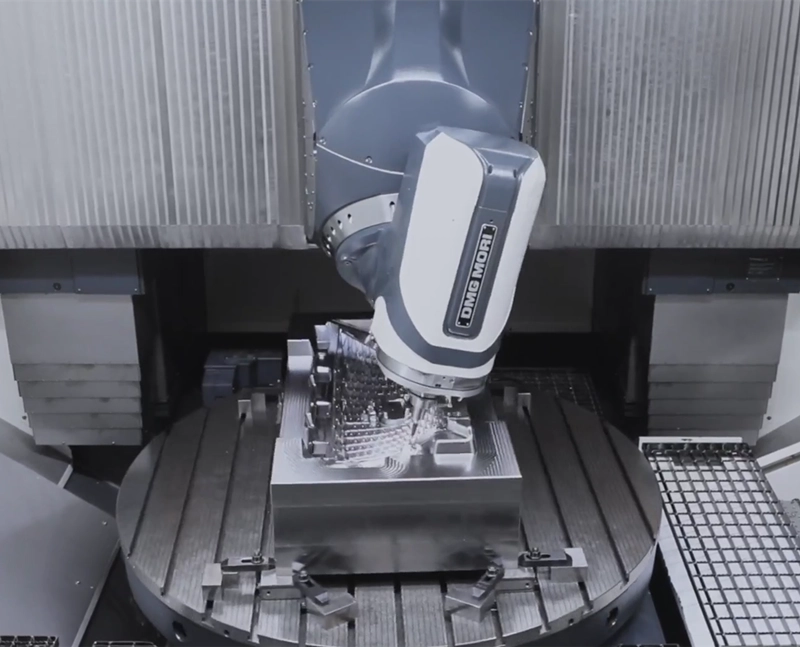

5-axis linkage CNC machining technology is a major leap in the field of mechanical engineering. Unlike traditional three-axis machine tools that can only perform simple linear motion in the three directions of Move to achieve simultaneous cutting from multiple angles. This innovative design greatly expands the processing possibilities and is especially suitable for aerospace, automotive, mold manufacturing and other industries that require highly complex shape processing.

Precise carving, impeccable

Imagine, whether it is the precision blades inside an aircraft engine, the smooth curves of a luxury car body, or the delicate threads in medical equipment, 5-axis CNC machining can accurately transform the designer's blueprint into reality. Its precision is high enough to impress any discerning eye.

Double efficiency and optimize costs

Even more exciting is that this technology also brings significant efficiency improvements. By reducing the number of workpiece clampings and avoiding multiple positioning errors, 5-axis machining significantly shortens the production cycle and reduces the waste of time and resources caused by resetting. This means that while ensuring quality, companies can respond to market demand faster and gain valuable competitive advantages.

Flexible and creative

For product manufacturers who pursue the ultimate in personalization, 5-axis CNC machining is undoubtedly the key to making their dreams come true. It can easily handle all kinds of whimsical design challenges, even the most complex geometries can be achieved in one go without compromise. This unprecedented flexibility frees innovation from the shackles of technology.

Easy to master, intelligent operation

It is worth mentioning that although it sounds high-end and complicated, modern 5-axis CNC machining centers are equipped with intuitive user interfaces and powerful programming software, so even beginners can get started quickly. Intelligent operating procedures, coupled with detailed tutorials and support services, ensure that every user can make full use of this advanced tool and unleash unlimited creativity.

Invest in the future with significant value

Of course, for such cutting-edge technology, the initial investment is naturally high. However, in the long run, it is an investment worth every penny. It can not only significantly improve production efficiency and reduce operating costs, but also open the door to the high-end market for enterprises and attract partners with strict quality requirements. Over time, this machine will become a powerful engine for business growth.

5-axis CNC machining is not only a product, it is your partner towards the pinnacle of precision manufacturing and the key to unlocking unlimited possibilities in the future. CNCKesu lets this power of change help your business stand out in the fierce market competition and achieve extraordinary results.

Principles and applications

Simply put, 5-axis CNC machining is an advanced manufacturing method that operates simultaneously on three linear axes (usually X, Y, Z) and two rotary axes. This multi-dimensional operating capability allows the machine tool to complete the machining tasks of almost any complex-shaped parts, whether it is an internal cavity or an external curved surface. Compared with traditional 3- or 4-axis CNC machine tools, 5-axis CNC machining significantly improves production efficiency and product quality, reducing the need for subsequent processing steps.

Analysis of technical principles

1.Coordinate system conversion

5-axis CNC machines provide additional degrees of freedom of control by mounting the workpiece on a table that can rotate about two mutually perpendicular axes. In this way, the tool can contact the workpiece surface at a more flexible angle, thereby avoiding the accumulation of errors caused by multiple clampings.

2. Programming optimization

In order to take full advantage of 5-axis machine tools, professional CAM software is widely used to generate efficient and accurate machining paths. These software can adjust cutting parameters according to specific needs and automatically calculate the optimal trajectory to avoid interference. In addition, they also support simulation functions, allowing engineers to preview the entire processing process before formal production, discover potential problems in time, and make corresponding adjustments.

Wide range of applications

Due to its excellent performance, 5-axis CNC machining technology has been widely used in many industries:

Aerospace : used to manufacture high-precision components such as aircraft engine blades;

Automobile manufacturing : improve the strength of the body structure while reducing weight;

Medical devices : Improve the safety and comfort of surgical tools and implants;

Mold making : speed up the new product development cycle and reduce production costs.

Advantages and Trends

Obvious advantages

Compared with traditional manufacturing methods, 5-axis CNC machining has the following advantages:

Higher flexibility : able to process products with various complex geometries;

Improve production efficiency : reduce the number of tool changes and auxiliary time;

Enhanced precision control : Reduces the chance of errors caused by human factors;

Reduce costs : Although the initial investment is large, in the long run you can save money by reducing the scrap rate.

Challenges and Development Trends

Although 5-axis CNC machining brings many benefits, it still faces some challenges in practical application, such as high equipment costs and high technical thresholds. To this end, the industry is actively exploring solutions, such as developing more affordable models and simplifying the design of operating interfaces. At the same time, with the development of artificial intelligence technology, it is expected that more new CNC systems with higher intelligence and stronger autonomous learning capabilities will appear in the next few years, further promoting the development of this field.

As an integral part of modern manufacturing, 5-axis CNC machining technology is attracting the attention of more and more professionals with its unique charm. If you also want your company to be at the forefront of technological innovation, you may wish to consider seeking professional consulting services, which can inject new vitality into your business.