Precision Machining

Challenges in Precision Machining

In the cnc precision machining world, where every micrometer counts, a slight deviation can critically impact product quality. Have you ever encountered production setbacks due to equipment inaccuracies? Or perhaps, the inability to perfectly realize your design because of technical constraints? These issues not only influence the performance of the final product but directly correlate with market competitiveness and customer satisfaction.

The Demand for Precision

Rapid precision machining is a field where the demand for exactness in dimensions and surface finish is paramount. As technology advances and market expectations rise, traditional methods fall short. From parts in the micron range for mechanics to nanoscale components for electronics, the precision bar is continuously raised, presenting unique challenges to cnc precision machining manufacturers.

Kesu's Precision Machining Solutions

Technological Innovation at Its Best

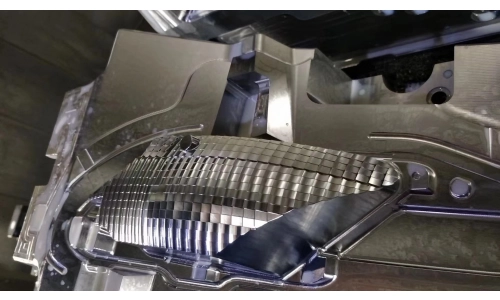

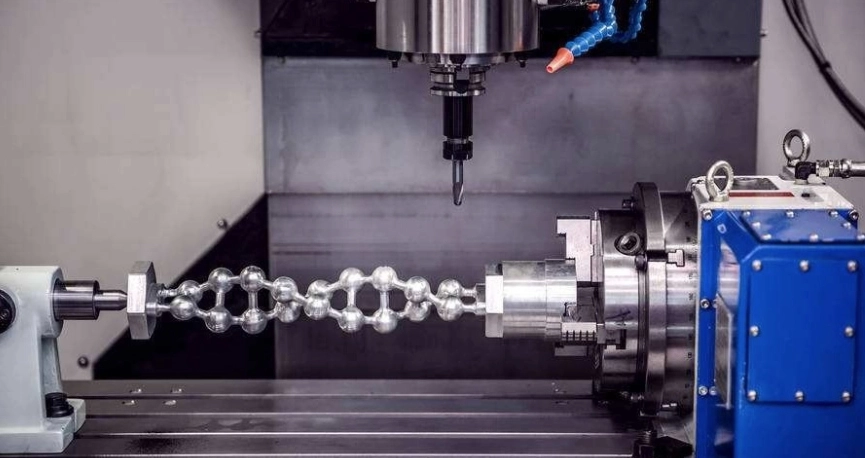

To tackle these challenges head-on, we at Kesu have introduced the latest generation of high-precision machining equipment. Leveraging cutting-edge CNC technology and precision measurement systems, we ensure that every cut and polish achieves the highest level of accuracy. Our intelligent software allows for complex machining paths to be set with ease, enhancing both efficiency and quality in cnc precision machining factory.

Detailed Features for Success

Our solutions are not just about meeting standards; they're about exceeding them:

Ultra-fine Control System: Equipped with advanced servo motors and precision ball screws, our machines control tool movement down to the micron, ensuring consistent and repeatable results.

Intelligent Error Compensation: Real-time monitoring with built-in sensors automatically corrects deviations, maintaining high precision even during extended operations.

Multifunctional Integrated Design: Our machines combine turning, milling, and grinding capabilities, reducing the need for multiple setups and saving on both space and investment.

| Feature | Benefit |

|---|---|

| Advanced CNC Technology | Enhanced accuracy and speed |

| Real-time Error Correction | Consistent quality over time |

| Integrated Machining Modes | Reduced equipment footprint and costs |

Real-World Impact: A Case Study

Consider a company focused on aerospace parts. By adopting Kesu's high-precision equipment, they boosted their product qualification rate by 30% and halved their delivery times. This not only improved their efficiency but also clinched more contracts with high-end clients in using CNC Precision Machining capabilities and specifications.

Working with Kesu

Negotiating Cooperation

Interested in revolutionizing your production line? We offer comprehensive services, from initial consultation to long-term support, ensuring you get the cnc precision machining co solution that fits your needs perfectly.

Investment and Value

While our technology represents the pinnacle of the industry, we strive to make it accessible with competitive pricing and flexible payment options. Investing in Kesu's solutions means bolstering your market edge and ROI.

FAQs

What makes Kesu's precision machining equipment stand out?

Kesu's equipment features advanced CNC technology, ultra-fine control systems, intelligent error compensation, and multifunctional integration for superior precision and efficiency.

How does Kesu's technology benefit my business?

By using Kesu's solutions, you can enhance product quality, increase production efficiency, shorten delivery times, and ultimately improve market competitiveness and customer satisfaction.

Can Kesu's solutions be integrated into my existing production line?

Yes, Kesu offers tailored consultation and integration services to ensure our high-precision equipment fits seamlessly into your current cnc manufacturing process.