Insert Molding

Insert molding

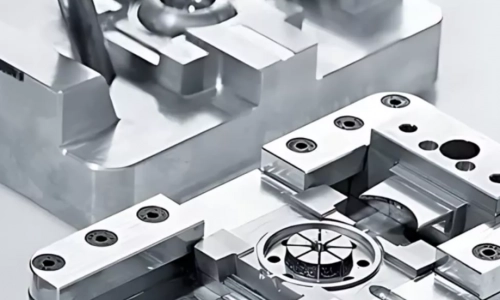

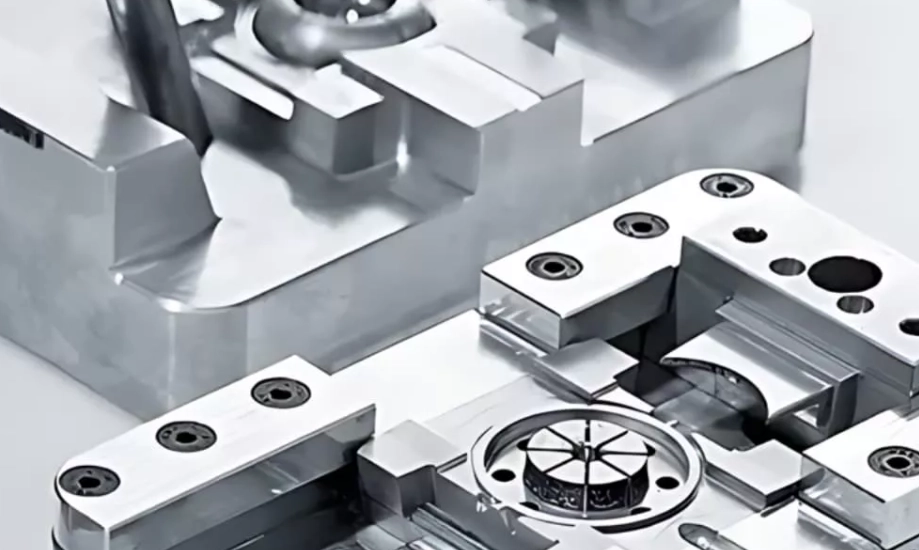

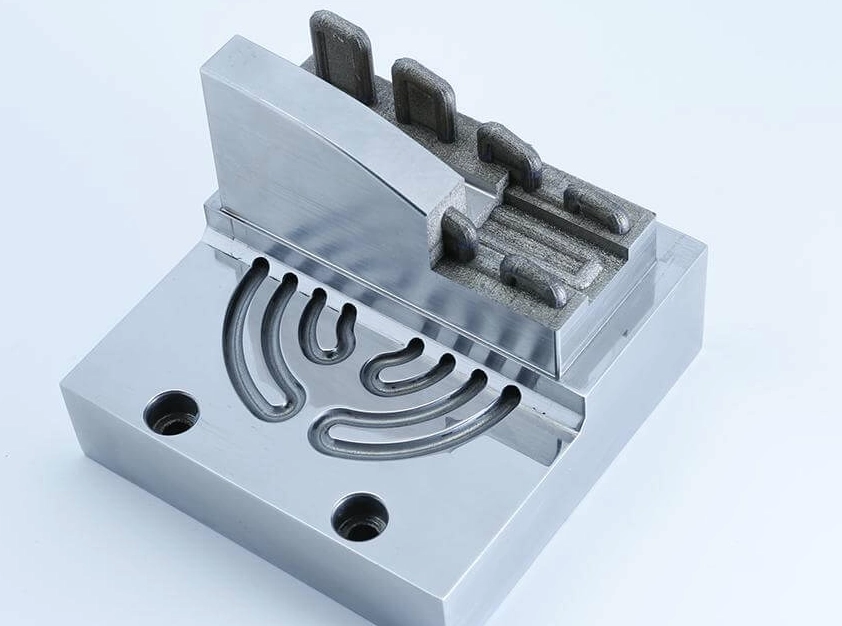

Insert molding, as an innovative manufacturing technology, plays a pivotal role in modern manufacturing. It involves placing a pre-shaped component into a mold and injecting a second material to join the two. This process not only improves production efficiency, but also significantly reduces production costs while ensuring product performance and quality.

In today's highly competitive market environment, companies are facing tremendous pressure to continuously innovate to meet consumer demand for high-quality, high-performance products. The emergence of insert molding technology provides a new solution for enterprises. Through this technology, companies can produce more durable, lightweight and cost-effective products to stand out in the fierce market competition.

The purpose of this article is to show how to promote the benefits of insert molding technology through emotionally intelligent copy. We'll dive into the core benefits of this technology, including how it can increase productivity, reduce costs, and optimize product performance. At the same time, we will also use specific industry cases to demonstrate the wide application of insert molding technology, emphasizing its flexibility and adaptability. In addition, we will share some stories of companies or individuals who have successfully adopted this technology to increase the credibility and appeal of the copy.

Finally, we will look at the future development prospects of insert molding technology, explore its potential opportunities in the market, and inspire readers' interest and confidence in this field. We hope that through this article, more people can understand the value and potential of insert molding technology, encourage them to consider adopting this technology, and jointly promote innovation and development in the manufacturing industry.

Core advantages

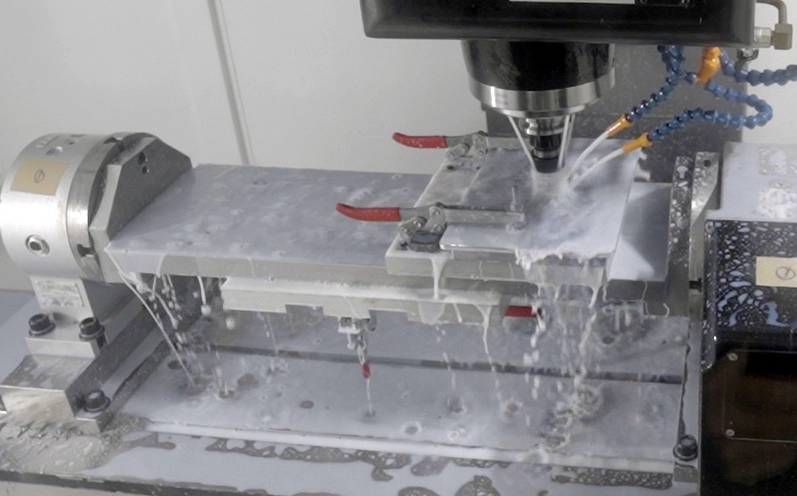

Among the many innovative technologies discussed in modern manufacturing, insert molding is undoubtedly a notable development. With its unique advantages, it has demonstrated significant leadership in cost-effectiveness, production efficiency and product performance optimization. Compared with traditional manufacturing methods, insert molding can achieve more refined production process control, thereby significantly reducing production costs and improving production efficiency. This is an irresistible attraction for manufacturers seeking to maximize profits.

Another outstanding advantage of insert molding technology is its great optimization of product performance. Through precise mold design and molding process control, this technology can ensure that the dimensional accuracy and structural complexity of products reach unprecedented heights. This not only improves the overall quality of the product, but also meets the growing market and consumer demand for high-performance products. In a highly competitive market environment, this improvement in capabilities undoubtedly gives companies a valuable competitive advantage.

The high efficiency of insert molding technology is also reflected in its shortened production cycle. Because inserts can be completed simultaneously with other parts in a single molding process, this significantly reduces subsequent assembly steps and time. The fast production cycle means that companies can respond to market demand faster and accelerate the launch of new products, thereby taking the lead in fierce market competition.

These core advantages together constitute the strong competitiveness of insert molding technology, making it an indispensable part of modern manufacturing. Whether in terms of cost control, production efficiency or product quality, insert molding technology has demonstrated its unique value and met the high standards of the market and consumers. With the continuous advancement of technology and the deepening of application, insert molding is expected to play a more important role in the future manufacturing field.

Scene display

In the automotive industry, insert molding technology has become the key to improving component performance and production efficiency. For example, a well-known automobile manufacturer uses insert molding technology to produce engine parts, which not only optimizes the use of materials, but also greatly improves the durability and strength of the parts. By perfectly combining metal and plastic, this technology makes it possible to lighten cars, thereby improving fuel efficiency and reducing emissions, meeting the market's dual needs for environmental protection and economy.

The field of consumer electronics has also witnessed the widespread application of insert molding technology. A leading smartphone manufacturer is using this technology to create phone cases that are both beautiful and sturdy. Insert molding allows the phone case to remain thin and light while having excellent drop and wear resistance. This innovative design not only attracts consumers' attention, but also enhances the market competitiveness of the product. By precisely controlling the production process, companies can achieve personalized customization to meet the unique needs of different consumers.

The medical device industry also benefits from the flexibility and precision of insert molding technology. One successful case is a high-precision surgical instrument produced by a medical device company. Using insert molding, they are able to integrate complex functional components into a compact and easy-to-handle instrument. This not only improves the accuracy and safety of surgery, but also shortens recovery time, giving patients a better treatment experience. In addition, the application of this technology also reduces production costs and makes high-quality medical equipment more popular.

Testimony sharing

In the wave of insert molding technology, many companies and individuals have achieved unprecedented achievements with this innovative technology. For example, after a well-known automobile manufacturing company adopted insert molding technology, not only its production efficiency was greatly improved, but the performance and safety of its products were also significantly enhanced, thus gaining a greater competitive advantage in the market. The person in charge of the company said: "Insert molding technology makes our products lighter and stronger, while reducing production costs. This is the key to our success."

Another case comes from the consumer electronics industry. An innovative technology company successfully launched a revolutionary smart wearable device by introducing insert molding technology. This device has a more compact design, more powerful functions, and an excellent user experience. It has been enthusiastically welcomed by consumers upon its launch. The founder of the company shared: "Insert molding technology allows us to integrate more innovative elements into product design to meet consumer demand for high-quality smart devices." These successful cases fully demonstrate the advancement of insert molding technology Huge potential for industrial upgrading and meeting diversified market demands.

Development prospects

Insert molding technology, as an efficient, precise and flexible modern manufacturing process, is leading industry changes with its unique advantages. With the advancement of science and technology and the continuous changes in market demand, the development prospects of this technology are full of infinite possibilities.

Judging from the latest industry trends, insert molding is developing towards higher automation and intelligence. By introducing advanced robotics, the Internet of Things, and artificial intelligence algorithms, the production process has become more precise and controllable, greatly improving production efficiency and product quality. At the same time, this also means that enterprises can respond to market changes faster and meet the needs of personalized customization, thereby standing out in the fierce market competition.

In addition, with the continuous emergence of new materials and new processes, the application scope of insert molding is also expanding. Whether it is lightweight design, complex structure manufacturing or the application of high-performance materials, insert molding provides broad development space. Especially in the fields of aerospace, new energy vehicles and other fields, the demand for high-performance and high-precision components is growing day by day. Insert molding will undoubtedly become one of the important manufacturing methods in these fields.

Looking to the future, insert molding technology is expected to achieve deep integration with other advanced manufacturing technologies, such as 3D printing, nanotechnology, etc., to further promote the transformation and upgrading of the manufacturing industry. This will not only bring about a significant improvement in production efficiency, but also spawn more innovative product forms and business models, injecting new vitality into the entire industry chain.

In short, the development prospects of insert molding technology are broad and far-reaching. It is not only an important part of modern manufacturing, but also a key force in promoting industrial upgrading and innovative development. For companies and entrepreneurs interested in exploring the field of advanced manufacturing, keeping up with the latest developments in insert molding and actively embracing this technological innovation will undoubtedly open a door to the future for them.