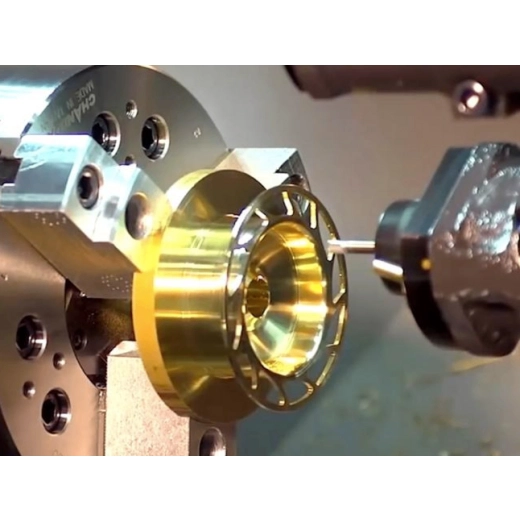

The Art and Science of Precision Brass CNC Machining

0.00

(1)5.0

SKU:CNCS0091

Mpn:CNCM0091

Category:Machining Parts

* The data is open source, not security confidential file from client.

Understanding CNC Machining with Brass

In modern manufacturing, achieving precision is not merely a goal but an absolute necessity. Brass, with its remarkable properties, stands out in the field of CNC (Computer Numerical Control) machining. Here's why précised brass parts has become indispensable in industries ranging from electronics to automotive.

Why Choose Brass?

Brass, an alloy of copper and zinc, is renowned for its ease of machining. Its low friction characteristics allow for higher cutting speeds and a smoother finish, which not only reduces wear on tools but also cuts down production times. The ability of brass to hold tight tolerances is crucial when manufacturing small, detailed parts that require exact specifications. This makes brass a material of choice for applications demanding precision, durability, and visual appeal.

The Precision of CNC Machining

CNC machining elevates the precision of precised brass parts by utilizing computer-controlled sequences to cut, shape, and finish parts with exceptional accuracy.

Tight Tolerances

CNC machines can work within tolerances as fine as ±0.0025 mm, ensuring parts match exact dimensions for perfect assembly or function. This level of precision is essential in applications where even the tiniest gap could lead to failure, like in connectors or valves.

Consistency in Production

The repeatability of CNC machining ensures that each part produced is virtually identical, a key aspect for quality control in mass production. This consistency is highly valued in industries like automotive and aerospace where reliability is paramount.

Complex Geometries

CNC's versatility allows the creation of complex shapes that traditional methods might not manage, thereby improving both the functionality and design of brass components.

Significance of Resistor Chips in Electronics

While brass machining focuses on mechanical precision, resistor chips are all about electrical accuracy, playing a pivotal role in electronic circuits.

Role in Circuit Design

Resistor chips manage electrical current and voltage, crucial for the performance of modern devices like smartphones and computers. Their small size and precision are essential in the dense, compact circuit boards of today.

Manufacturing Precision

Similar to precised brass parts CNC at a micro-scale, the production of resistor chips requires extreme accuracy, where even minor deviations can impact the whole circuit's performance.

Recalibration for Optimal Manufacturing

The precision of CNC machines isn't a set-it-and-forget-it feature; it demands ongoing maintenance through recalibration to counteract natural wear and deviations.

Tool Wear and Calibration

Tools wear over time, which can affect dimensions. Regular recalibration adjusts for this, ensuring outputs remain within tolerance.

Adjusting for Environmental Factors

Changes in temperature, humidity, or machine usage can influence précised brass parts. Calibration tweaks machine settings to compensate for these variables.

Methods of Calibration

Calibration might use tools like calipers or micrometers, and modern CNC machines often have software to make this process more efficient and less error-prone.

| Aspect | Impact on CNC Machining |

|---|---|

| Tool Wear | Can lead to dimensional inaccuracies; recalibration maintains precision. |

| Environmental Conditions | Affects part consistency; calibration adjusts machine parameters. |

| Complex Geometry | Enabled by CNC, allowing for innovative part designs. |

FAQs

Why is brass preferred for CNC machining?

Brass is favored for CNC machining due to its excellent machinability, corrosion resistance, and aesthetic qualities. Its low friction reduces tool wear and speeds up the machining process while maintaining precision.

What is the significance of resistor chips in electronics?

Resistor chips are vital in electronics for controlling current, setting voltage levels, and ensuring circuit stability. They are especially important in high-density circuit boards where space and precision are critical.

What does recalibrating a CNC machine involve?

Recalibration involves adjusting for tool wear, environmental changes, and mechanical deviations using precision tools like calipers or laser systems, ensuring the machine continues to produce parts within specified tolerances.