How to Find CNC Turning for Motor Shaft with Poor Dimensional Stability: A Comprehensive Guide for Optimal Solutions

0.00

(3)5.0

SKU:CNCS0023

Mpn:CNCM0023

Category:Machining Parts

* The data is open source, not security confidential file from client.

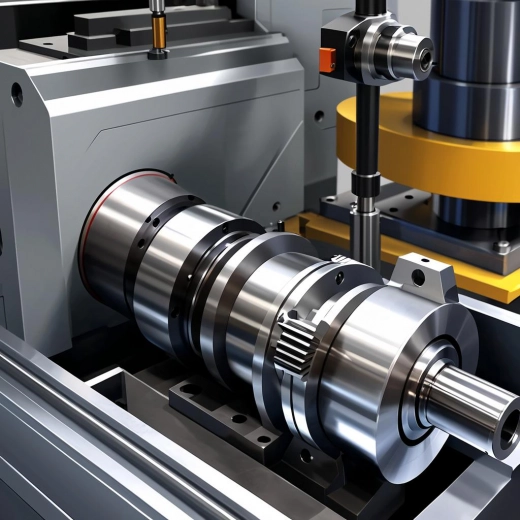

Understanding the Problem of Poor Dimensional Stability in Motor Shafts

The Significance of Dimensional Stability

Dimensional stability is crucial for motor shafts as it directly impacts the performance and reliability of the entire motor system. A motor shaft with poor dimensional stability can lead to issues such as misalignment, vibration, and premature wear of components. When the dimensions of the shaft change over time or under different operating conditions, it can cause problems in the rotational balance and smooth operation of the motor.

Causes of Poor Dimensional Stability

There are several factors that can contribute to poor dimensional stability in motor shafts. One common cause is the choice of materials. If the material used for the shaft has a high coefficient of thermal expansion, it may experience significant dimensional changes with temperature variations. Additionally, improper manufacturing processes, such as insufficient heat treatment or inaccurate machining, can also lead to dimensional instability. For example, residual stresses within the shaft material can cause it to deform over time.

How to Identify CNC Turning for Motor Shafts

Researching CNC Turning Service Providers

When looking for CNC turning for motor shafts, it is essential to research and identify reliable service providers. Start by looking for companies with a proven track record in precision machining and experience in working with motor shafts. Check online reviews, industry forums, and customer testimonials to get an idea of their reputation and the quality of their work. You can also ask for recommendations from colleagues or other professionals in the industry.

Evaluating Machining Capabilities

Once you have shortlisted a few service providers, evaluate their machining capabilities. Look for companies that have advanced CNC turning equipment with high precision and accuracy. They should be able to handle the specific requirements of motor shaft machining, such as tight tolerances and complex geometries. Inquire about their ability to work with different materials and their quality control processes to ensure consistent and reliable results.

Checking for Certifications and Standards

It is important to choose a CNC turning service provider that adheres to industry standards and holds relevant certifications. Certifications such as ISO 9001 indicate that the company has a quality management system in place to ensure the highest level of quality and consistency in their machining operations. This gives you confidence that the motor shafts produced will meet the required specifications and standards.

Solutions for Improving Dimensional Stability in CNC Turned Motor Shafts

Material Selection

Choosing the right material is key to improving dimensional stability. Materials with low coefficients of thermal expansion, such as certain alloys and ceramics, are preferred for motor shafts. These materials are less likely to experience significant dimensional changes with temperature variations. Additionally, materials with good mechanical properties and resistance to wear and corrosion can enhance the overall performance and longevity of the shaft.

Optimizing Machining Processes

CNC turning processes can be optimized to improve dimensional stability. This includes using appropriate cutting tools, cutting parameters, and machining strategies. For example, using high-quality cutting tools with sharp edges can reduce cutting forces and minimize material deformation. Controlling the cutting speed, feed rate, and depth of cut can also help achieve more accurate and stable machining results.

Post-Machining Treatments

Post-machining treatments can further enhance the dimensional stability of motor shafts. Heat treatment processes such as annealing or stress relieving can remove residual stresses from the material, reducing the risk of deformation over time. Surface treatments like coating or plating can provide additional protection against wear and corrosion, improving the overall quality and stability of the shaft.

Conclusion

In conclusion, finding the right CNC turning for motor shafts with poor dimensional stability requires careful consideration of various factors. By understanding the causes of dimensional instability, identifying reliable service providers, and implementing appropriate solutions, you can ensure the production of high-quality motor shafts with excellent dimensional stability. This, in turn, will contribute to the reliable and efficient operation of motor systems in a wide range of applications.