Witness The Progress Of China's Copper Processing Industry! Celebrating The 70th Anniversary Of The Founding Of The Luo Copper Factory, Old Objects Were Unveiled!

Colorful flags were flying and guests were arriving in an endless stream.

In late autumn, on the occasion of the 70th anniversary of the establishment of Luoyang Copper Factory, the "Luoyang Copper Memory 70 Years Old Objects Exhibition" kicked off at Chinalco Luoyang Copper Processing Co., Ltd.

In the elegant Soviet-style building, everything is available, including books, work certificates, seals, various bronzes, honorary trophies, and pieces of meritorious equipment, more than 30 groups (sets), more than 100 exhibits, and old factory equipment. It left a deep impression on the visiting merchants from all over the country and the old cadres and workers of Luoyang Tong, and also awakened the industrial memory of many old Luoyang people.

What glorious history has the old industrial base witnessed? What progress does a comparison of the past and present reveal? Luobao Media reporters will take you to find out.

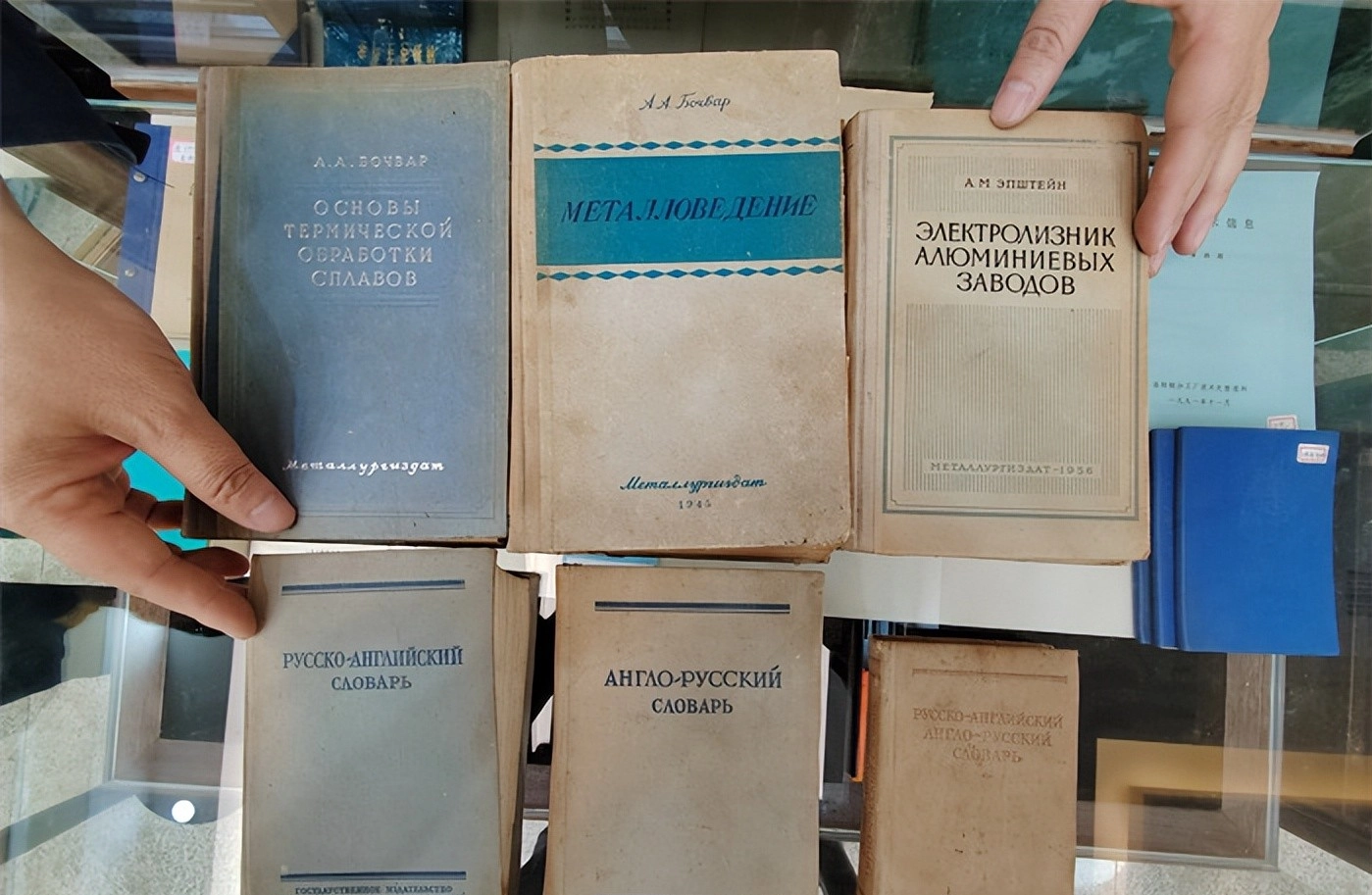

Several old books bear witness to Luo Tong's "from nothing to something, from something to strength"

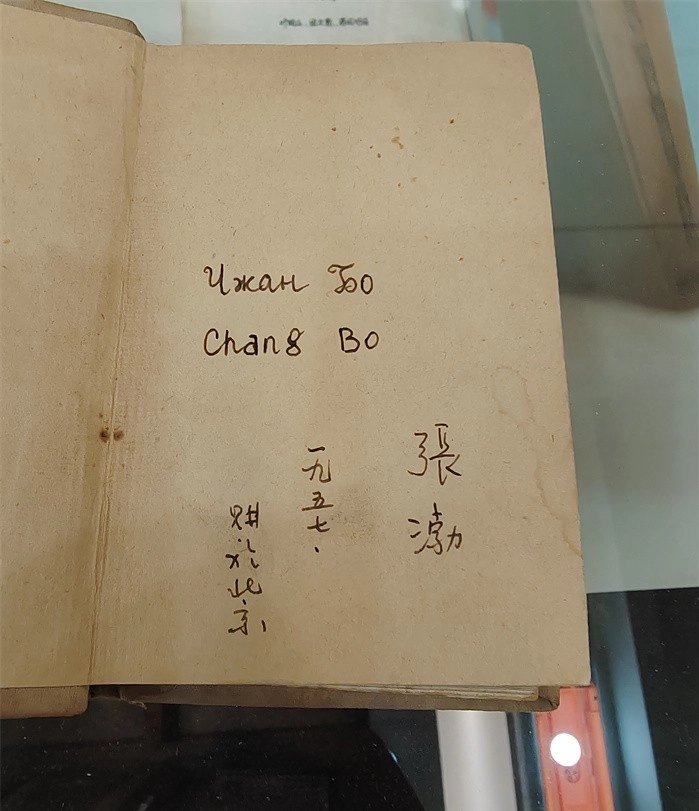

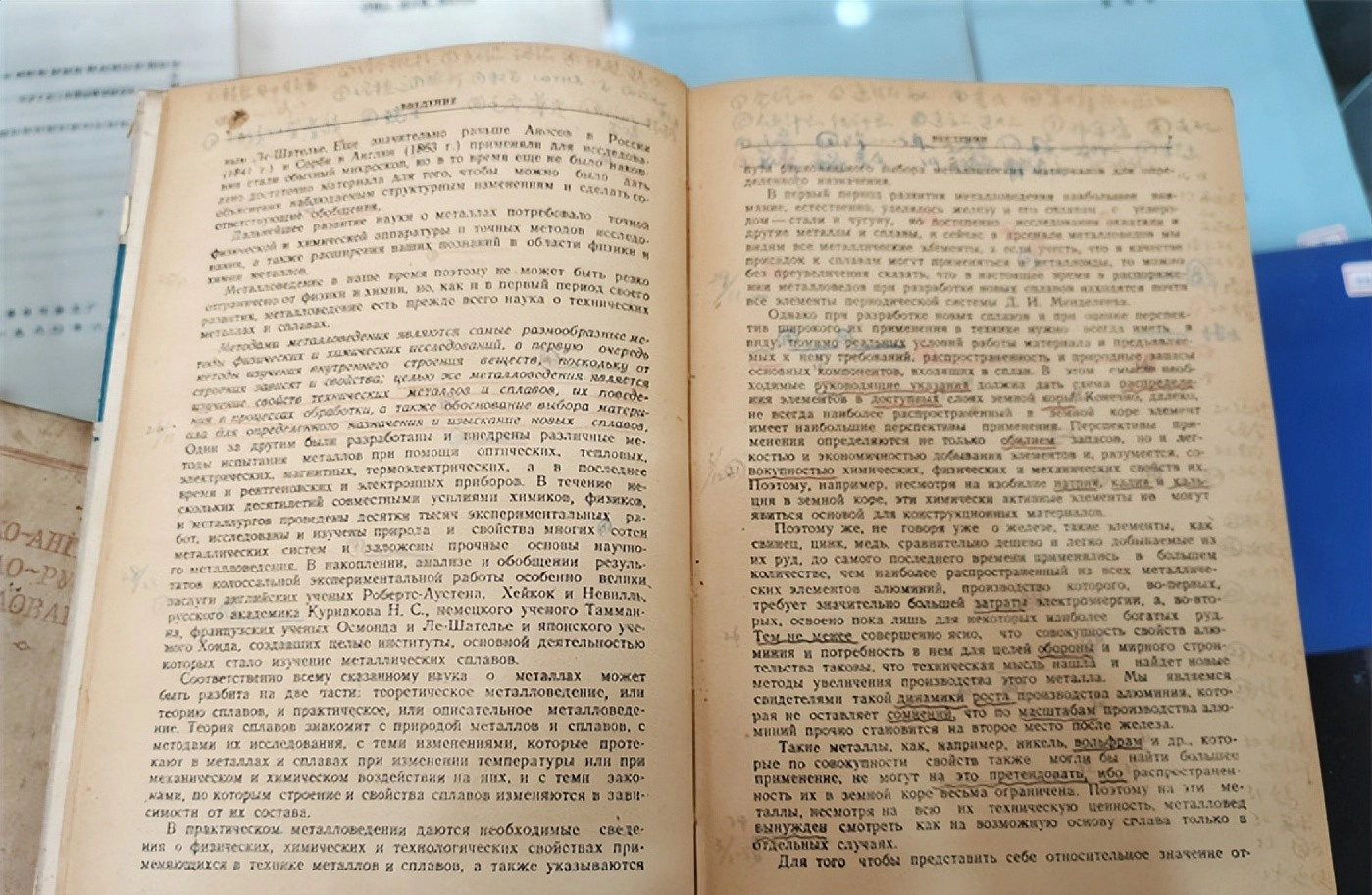

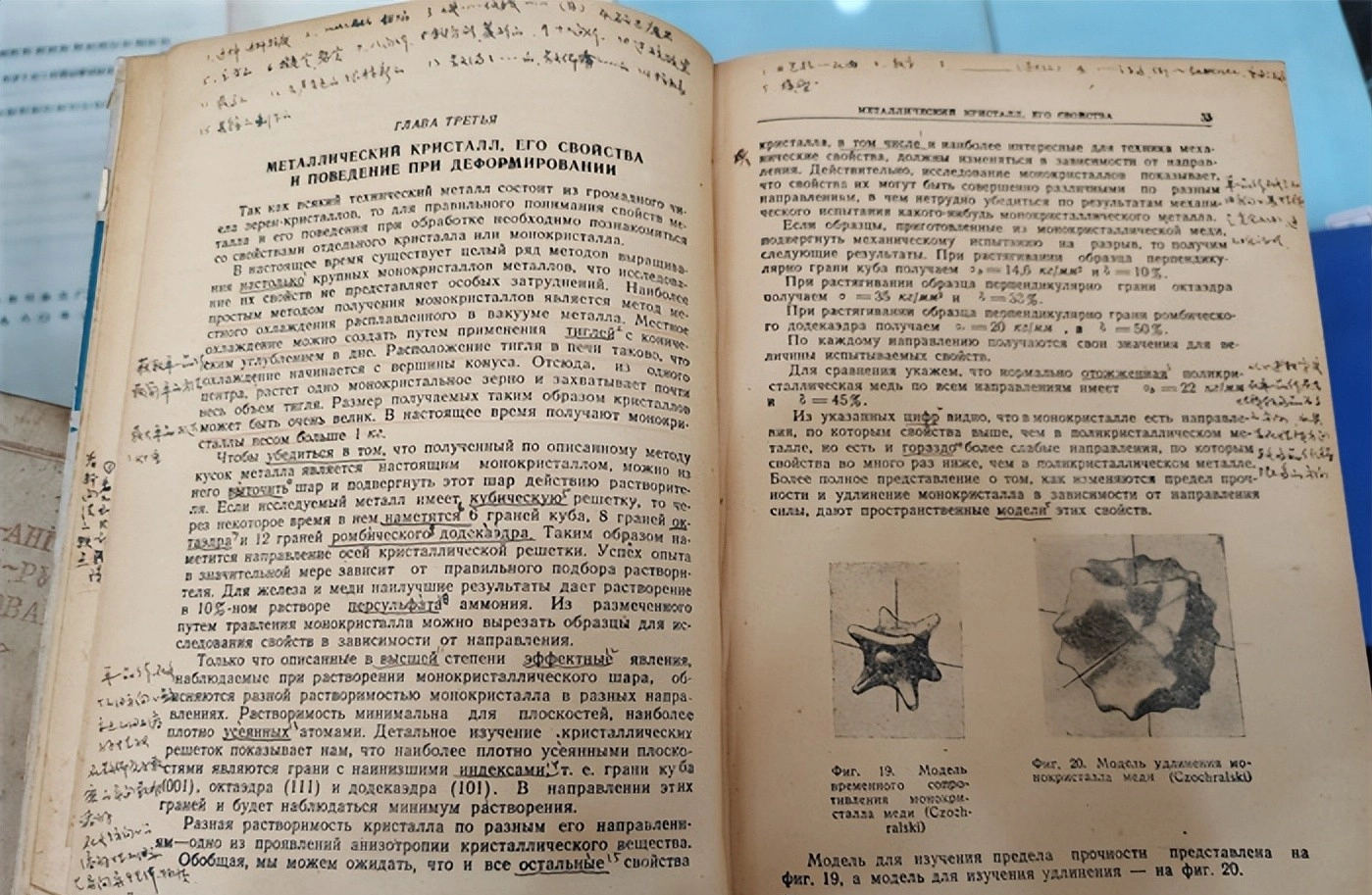

In the glass display case of the old objects exhibition, there is a yellowed Russian technical monograph "Metallography". The title page reads "Zhang Bo purchased it in Beijing in 1957", silently telling the owner and origin of this book. . Book.

Open the main text, and the blank space on each page is densely filled with Chinese terminology translations and learning experiences. "Lying" in the display case of this Russian monograph are Russian-English dictionaries and other learning materials.

"While overcoming the language barrier, I was learning technology, and now I have to learn and use it, which shows how difficult the conditions were at that time." Zhu Yong, the person in charge of the exhibition, said that in the early days of the factory's establishment, many cadres and technicians lacked this knowledge. expertise. Luo Tong studied Russian and organizational techniques. Everyone actively responded to the call and walked more than ten miles to the construction site during the day to drill holes in the ancient tombs and process the foundations. In the evening, they continue cultural studies and sometimes do homework until midnight. It's very cold in the room in winter, but everyone's enthusiasm for learning has not diminished at all.

Especially after the former Soviet Union withdrew its experts in the 1960s, Luotong technicians "gnawed" through these documents and information bit by bit, installed the remaining equipment in place, and put it into production. From the establishment of the factory in 1954 to its completion in 1965, the long construction period and arduous process of Luotong's construction can be seen.

If the Russian book tells the story of a difficult journey, then another journal, "Copper Processing", symbolizes the end of hardship and the end of joy.

This green "Copper Processing" journal has a big red "1" written on the cover. It was founded in 1981 by the Heavy Nonferrous Metals Branch of China Nonferrous Metal Processing Industry Association. It is an authoritative journal for my country's copper processing industry. In the "Publishing" address column on the back of the journal, "Luoyang Copper Processing Factory" is clearly marked.

Zhu Yong introduced that at that time Luotong was the largest comprehensive copper processing enterprise in China, with equipment and technology leading the country. There is a saying circulating in the industry: "If Luotong can't make products, no one in the country can."

"Naturally, the Heavy Nonferrous Metals Branch is located in Luo Copper Factory and is responsible for publishing this magazine." Zhu Yong said that so far, Luo Copper Industry has formulated and revised 202 national and industry standards, accounting for 20% of the standards in use in the copper processing industry. 20%. More than 30%, it is the main setter of the current national and industry standards in the copper processing industry. The "gold-letter brand" style remains unchanged and will last forever.

Euro coinage material used to record batch information

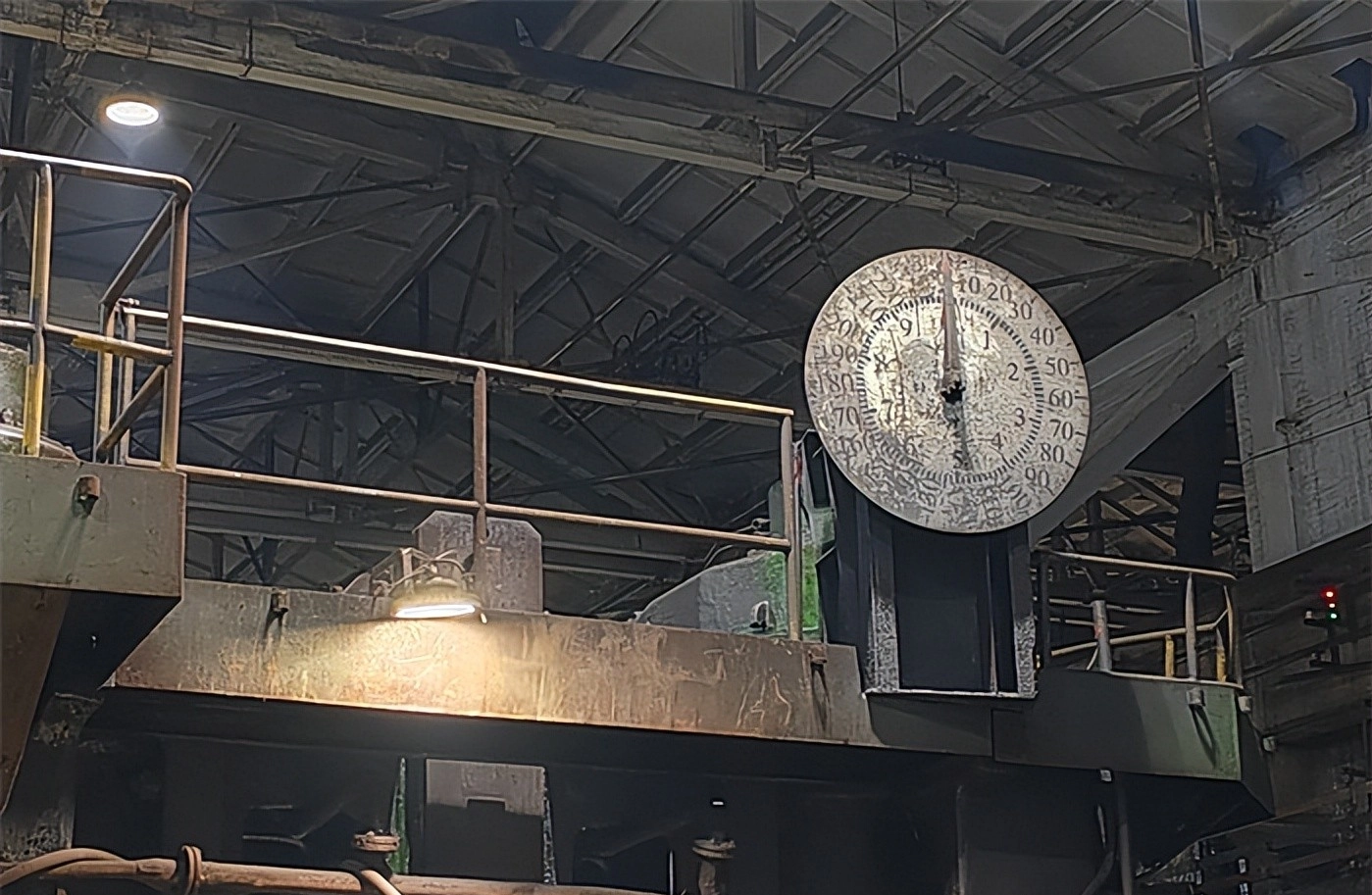

It is about half a meter in diameter. Although it looks rusty, it is as smooth as new.

In the corner of the old objects exhibition area, a retired "European coding machine" is particularly eye-catching. As the circular handle is turned, the hands point to the numbers, subtitles and symbols on the dial in sequence.

"It works like an old-fashioned printer. Select a character, press the operating lever hard, and the character will be printed on the mold. The batch, model and other information of the euro coinage material will be printed on the finished mold," Zhu Yong said. .

Why does European coinage focus on “Made in China”? We have to start from the early 1980s.

In the early days of the country's opening up, Luotong's need for equipment upgrades became increasingly urgent. Luotong raised 156 million yuan in funds and introduced 19 sets (sets) of advanced equipment from developed countries such as Germany, Italy, and the United States. This set off the first wave of technological transformation since the establishment of the factory, making Luotong's copper plate and strip production technology one of the best at the time. Internationally advanced.

"The euro coinage material is a rare multi-component copper alloy with complex main chemical components and very strict content requirements. China has never produced this kind of alloy of copper, aluminum, zinc and other metals before," Zhu Yong recalled. At that time, many companies from the United States, Germany, South Korea and other countries around the world had applied to the EU. However, due to workmanship defects, these companies did not even deliver samples at that time.

In 1998, with its advanced technology, as the 13th company to apply to the EU, Luotong produced 50 tons of samples in more than a month, defeating a group of international giants and shouting "Made in China" in the international market!

The 118-year rolling mill has witnessed history, and the "successor" has "Chinese origin"

The machine roars and the heat rises.

Walking into the thick plate operation area of Luo Copper Plate and Strip Factory, the wide thick plate rolling mill is like rolling out dumpling wrappers, rolling red-hot copper ingots into copper plates with uniform thickness.

This rolling mill was born in 1906 and was shipped to Luoyang Copper during the construction period of the former Soviet Union. It is now 118 years old and covered in green metallic paint. After a hundred years, it is still shining brightly.

"Although it is old, it is solid and powerful in use. It is still the copper rolling mill with the widest rolling size in Asia." Liu Xiaoliang, the person in charge of the wide and thick plate section of the plate and strip factory, was full of pride. The rolling mill rolled off the production line and produced my country's first large-scale copper rolling mill. copper plate. This copper plate was made into a plaque for the "Military Museum of the Chinese People's Revolution". The name of the museum was inscribed by Chairman Mao himself, and it still shines brightly today.

Heavy plate rolling mill mechanical instrument panel

It has a glorious past, and its "successor" has a bright future.

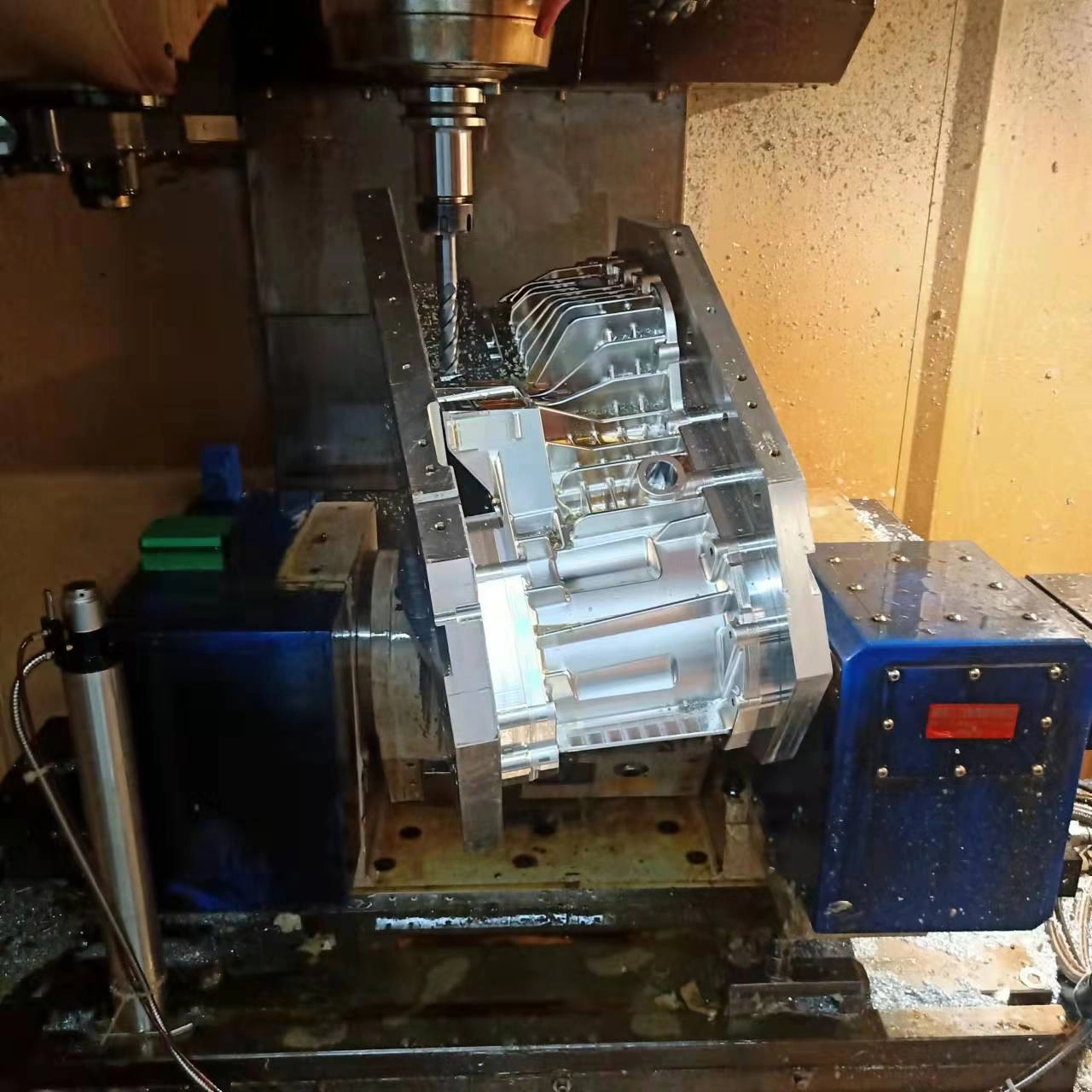

Currently, Luotong is building a new copper and copper alloy wide and thick plate production line. Different from the equipment imported from Europe and the United States aided by the Soviet Union when the factory was built in the 1980s, the ultra-large roll grinders required for this project, such as heat treatment annealing furnaces and ultrasonic flaw detectors, are all made in China.

Among them, the equipment that replaced the meritorious rolling mill - the four-roller reversible wide plate rolling mill with a maximum rolling width of 3500 mm, is the first independently developed equipment in the country to be used in the field of copper and copper alloy plate rolling, and is a true "Chinese origin" , marking that China’s copper processing industry is moving towards a higher level of self-reliance and self-reliance!

It is understood that as the "eldest son of the Republic", Luotong created many "firsts in the Republic" such as the first copper ingot in New China, and was equipped with high-thrust launch vehicles, electron-positron collider, manned spacecraft, etc. spacecraft and other “significant forces.” As of last year, Luoyang Copper's operating revenue exceeded the 10 billion mark, and its annual production and sales exceeded historical highs for three consecutive years.

"In the future, we will closely focus on the strategy of manufacturing a powerful country, continue to increase technological innovation, and move towards becoming a leading domestic and world-class copper processing enterprise." said the relevant person in charge of Luo Copper.

Seventy years will change the days, seventy years will last forever. Now, the 70-year-old Luo Tong is once again embarking on a new journey and continues to write a new legend in China's copper processing industry!