Core Link To Precise Mold Parts Handling To Improve Mold Performance

In the field of mold manufacturing, precision mold spare parts treatment is the core link in improving mold performance and has had a profound impact on the quality, accuracy, life and production efficiency of molds.

High precision processing is a key advantage in handling the precision mold part. The performance of the mold is highly dependent on the exact fit of each internal spare. For example, the core and cavity in the injection mold can be controlled within a small range by precise machining, thereby ensuring dimensional accuracy and surface quality of the injection molded product. This high precision allows mold to steadily produce products that meet strict standards in the production process, reduce interest rates, improve production efficiency and bring higher economic benefits to the enterprise.

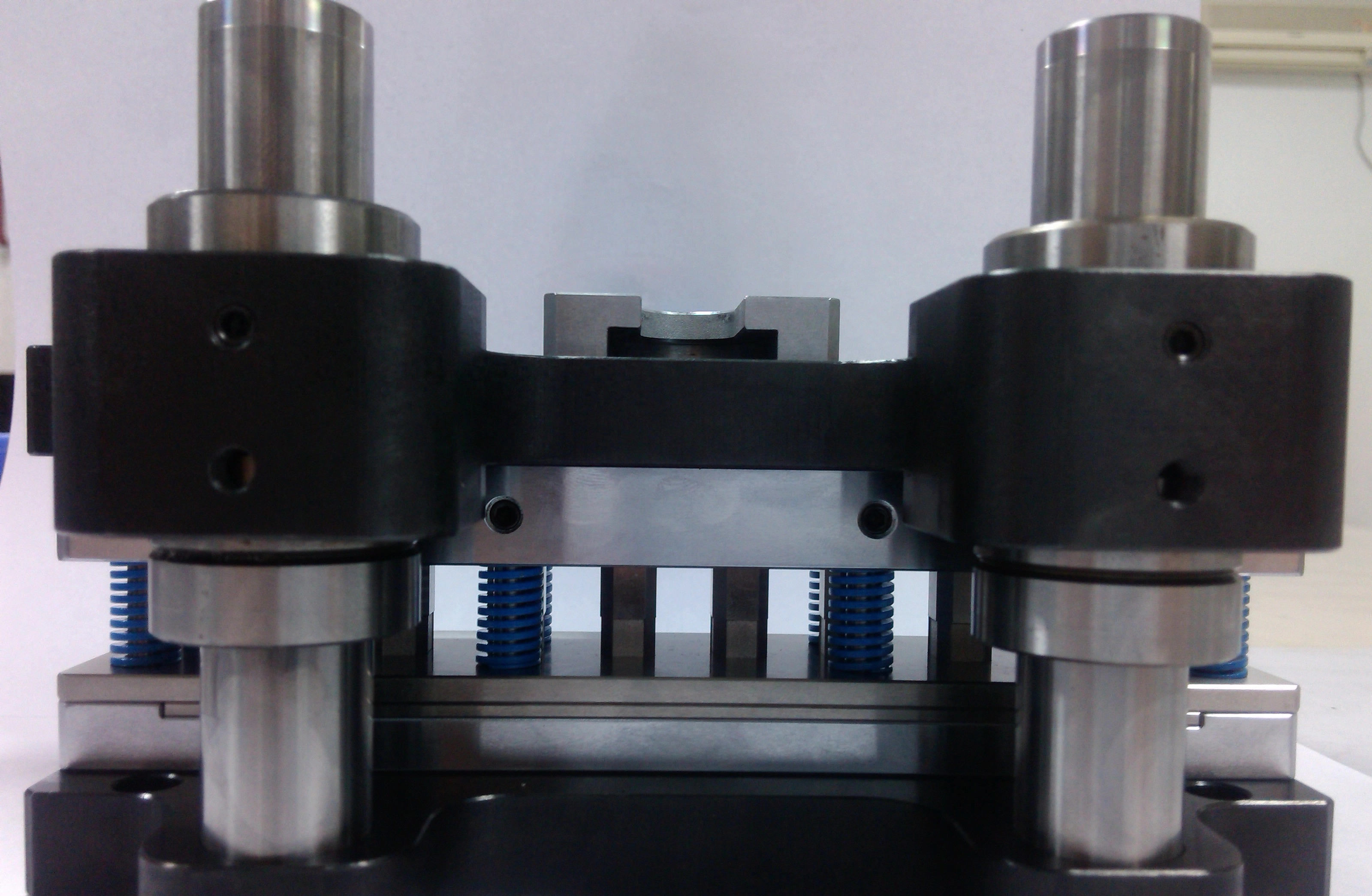

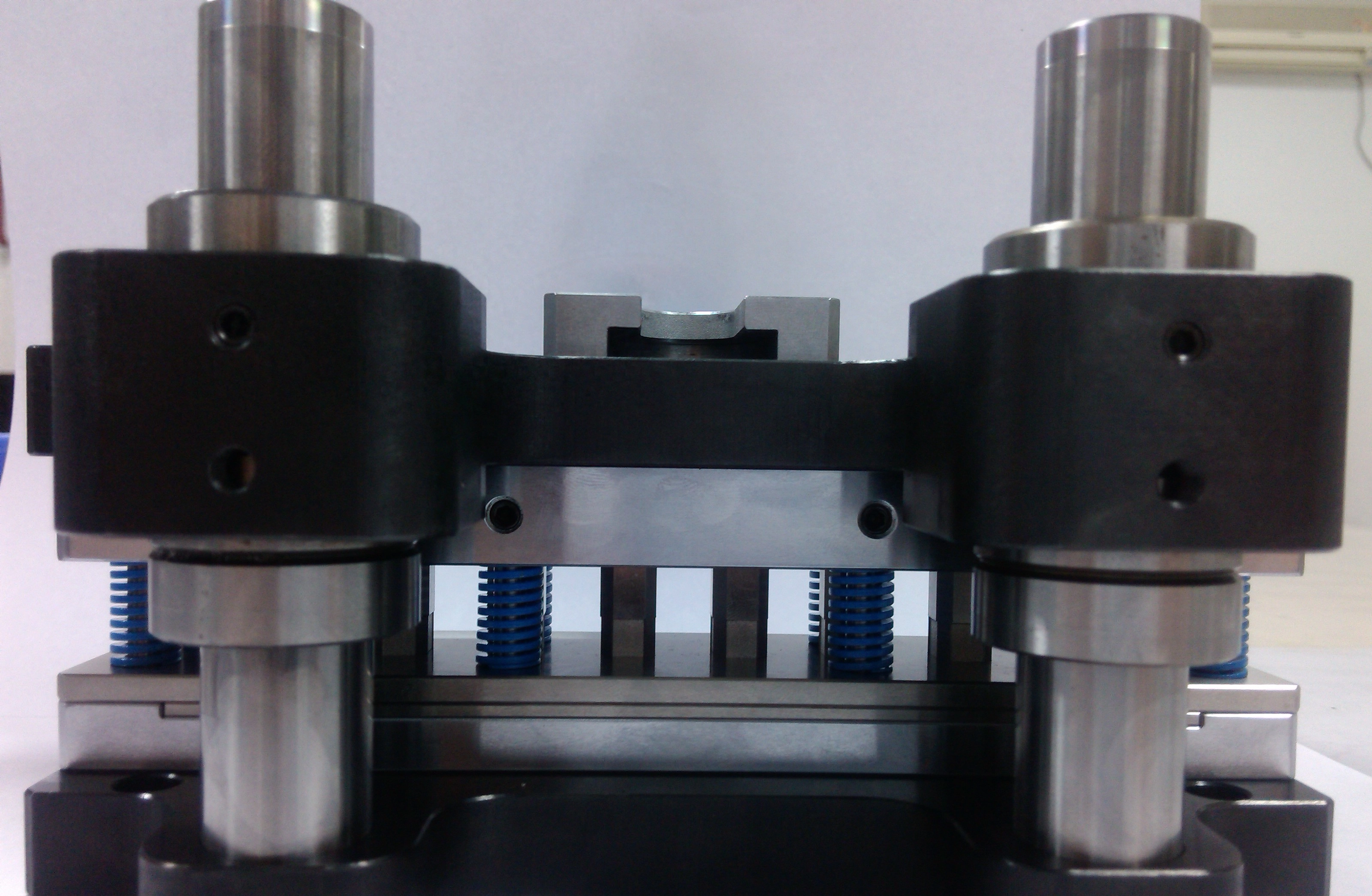

Precision mold parts processing

High-quality material selection and treatment are important aspects of precise mold parts processing. Depending on the different application solutions and performance requirements of the mold, please select the correct material, such as high strength, high wear steel. During the treatment process, proper heat treatment of the material (such as quenching, tempering and other processes) can significantly improve the hardness, toughness and wear resistance of the material. Taking stamping molds as an example, carefully processed and well-treated spare parts can withstand greater influence. During long-term stamping operations, they maintain a stable shape and size, greatly extending the service life of the mold.

Precise surface treatment is also key to improving mold performance. By surface treatment methods such as polishing and hard chrome plating, the surface roughness of the mold site is reduced and the friction coefficient is reduced. This not only helps the opening and ending action of mold, but also reduces energy loss, improves the release performance of mold and avoids problems such as strain and deformation during product release. For some molds with high demand for surface quality, such as optical crystal molds, precise surface treatment is a key factor in ensuring product optical performance.

Precision mold spare parts treatments can comprehensively improve the performance of molds from multiple dimensions, such as precision control, material optimization and surface treatment. This is an important force in promoting the development of mold manufacturing industry towards high precision and high performance, and provides reliable technical support for product manufacturing in various industries.