High-precision Mechanical Parts Processing Promotes Industrial Development

In modern industrial systems, high-precision mechanical parts processing plays an important role and is a key force in promoting industrial development.

High-precision mechanical parts are the basis for ensuring high-performance operation of industrial equipment. Taking aircraft engines as an example, internal parts (such as blades, turbine discs, etc.) require extremely high machining accuracy. These components work in extreme environments of high temperature, high pressure and high speed. Any slight dimensional deviation can lead to engine performance degradation and even serious accidents. Only by ensuring dimensional accuracy, surface roughness and other aspects of the parts meet stringent standards through high-precision machining can the engine be ensured to be efficient and stable and provide reliable power for the safe flight of the aircraft.

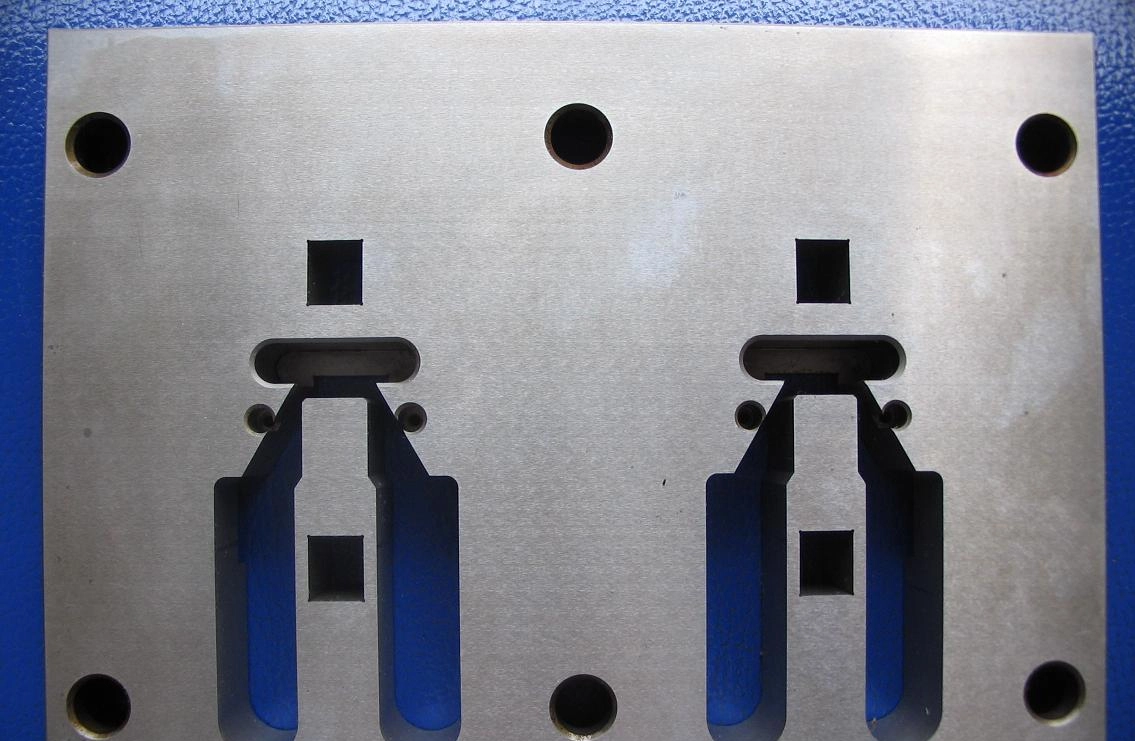

High-precision mechanical parts processing

Improvement of product quality is inseparable from the handling of high-precision mechanical parts. In the automotive manufacturing industry, the accuracy of core components such as engines and transmissions directly affects the power performance, fuel economy and reliability of the car. Precisely produced components such as pistons and gears can effectively reduce mechanical friction and energy losses, reduce vehicle failure rates, and extend service life, thereby improving the overall quality of the vehicle and enhancing the competitiveness of the enterprise in the market.

High-precision mechanical parts processing is also an important support for promoting industrial technological innovation. In the semiconductor manufacturing industry, chip manufacturing requires extremely high lithography equipment and precise molds. With the continuous development of technology, chip integration and performance requirements are becoming increasingly high, which has led to a continuous breakthrough in the processing technology of high-precision mechanical parts, and has developed more advanced processing technologies and equipment, such as extreme ultraviolet lithography. technology. It has opened up a new path for the development of the semiconductor industry.

High-precision mechanical parts processing

In addition, high-precision mechanical parts processing can also promote the coordinated development of related industries. It puts higher requirements on industries such as raw materials, processing equipment and testing tools, promotes continuous innovation and upgrading of these industries, forms a complete industrial chain ecosystem, and promotes the entire industrial system toward high-end and intelligentization develop.

In short, high-precision mechanical parts processing operates in all aspects of industrial production and plays an irreplaceable and important role in improving the performance of industrial equipment, ensuring product quality, and promoting technological innovation and industrial upgrading.