How Automotive Industry Companies Use Large DK7740B Wire Cutting Machines To Enable Effective Precision Processing

In today’s highly competitive automotive manufacturing industry, every innovation and advancement can be the new benchmark for the industry. Imagine how exciting it would be if there was a technology CNC search that could shape the hardest metal to ensure vehicle safety and reliability! Today, we will explore the large wire cutting machines used in the automotive industry as we manufacture braking system components and the transformative impact it brings.

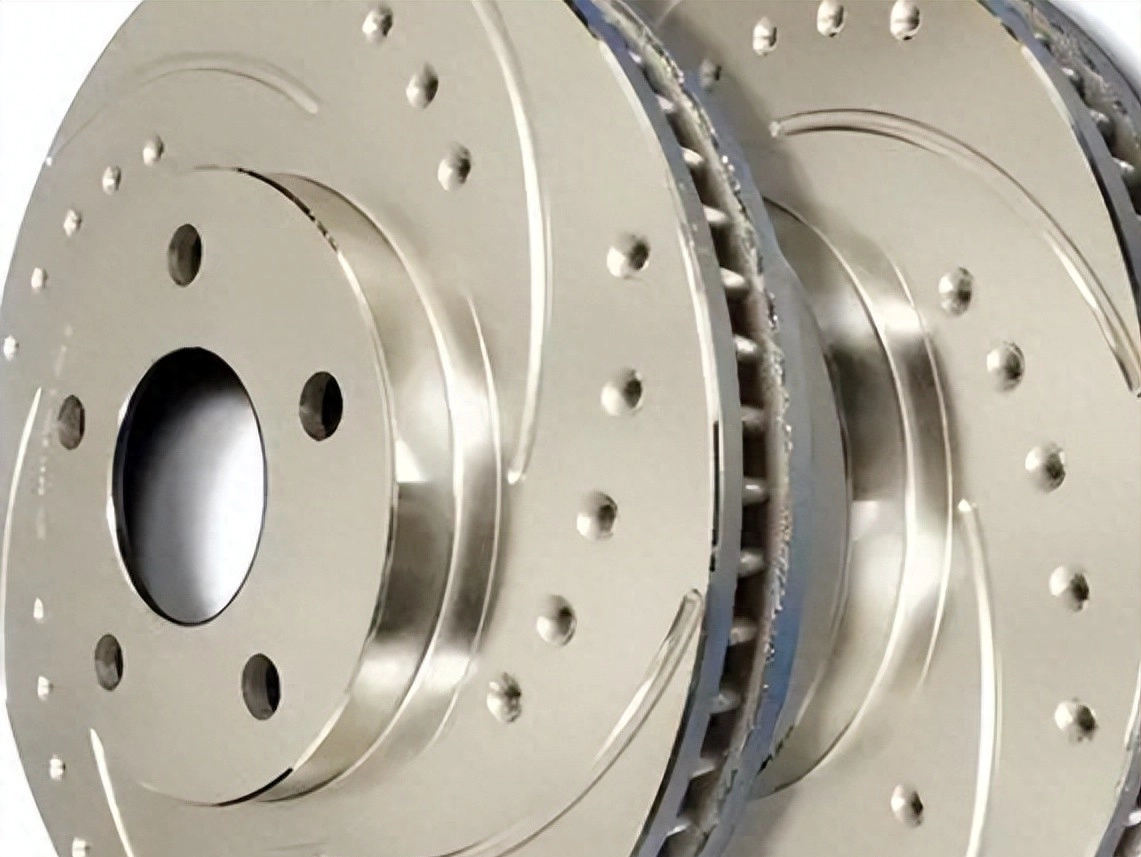

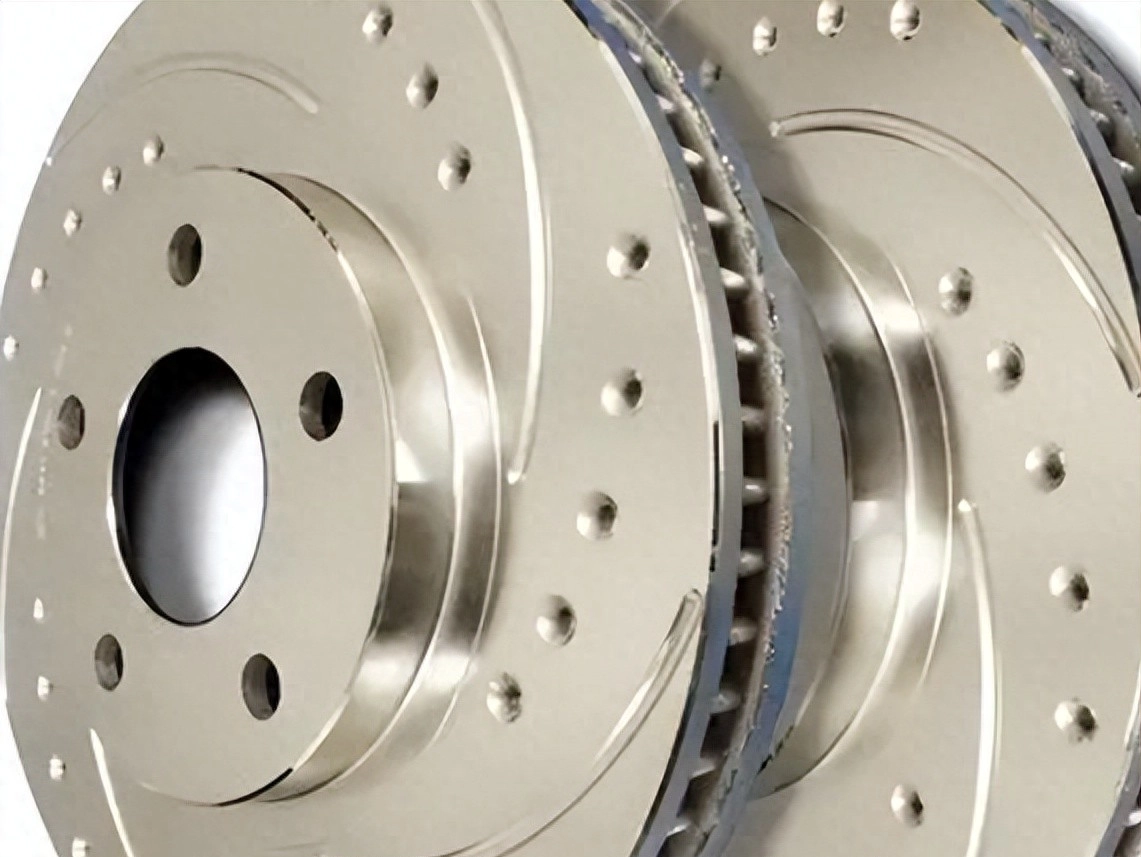

As a core part of the safety performance of a car, the brake system not only needs to have extremely high strength and wear resistance, but also must ensure dimensional accuracy to ensure optimal operating condition. During the production process, key components such as brake discs and brake drums are often handled using large wire cutting machines.

Take the case customers as an example, they encountered some significant technical challenges in the manufacturing of brake system components. First, due to the extremely high hardness of the materials (such as cast iron or special alloys), it is difficult to meet traditional processing methods; second, complex geometry and strict tolerance requirements make the processing extremely complex. Finally, modern brake systems are often designed with lighter and higher performance in order to improve braking efficiency and reduce wear, which undoubtedly increases manufacturing difficulties. By adopting large wire cutting machines provided by CNC, customers have successfully overcome the above problems and achieved significant improvements in product performance.

Data shows that since the introduction of CNC equipment, customers have improved production efficiency by 30%, while scrap rate has decreased by about 35%. More importantly, CNC has always adhered to technological innovation and continuously optimized equipment performance, so the accuracy of the final product has reached an unprecedented level. In addition, CNC provides a one-stop after-sales service system that runs from equipment installation and commissioning to maintenance and tracks services throughout the process, so customers don't have to worry.

"Every technological breakthrough is an important step towards the future." This sentence applies not only to CNC metal, a company at the forefront of technology, but also to companies like CNC, focusing on technology research and development and services. In addition to the outstanding performance in manufacturing brake system components, the CNC also exhibits strong strength in cutting multiple other components. Whether it is the complex structural part of the engine block or the suspension system, CNC can provide customized solutions to help customers solve various complex processing problems.

In short, on the road to pursuing extreme precision manufacturing, CNC has become an ideal choice for many automotive companies with in-depth R&D background and complete service networks. "Quality is the foundation of trust, and innovation is the driving force of development." This is not only the brand philosophy of CNC, but also the real experience of every user who chooses CNC. In this rapidly growing era, CNC will continue to help more companies succeed with their outstanding technology and high-quality services. Let us work together to open up a brighter tomorrow through wisdom and technology. Whether in current projects or future exploration, CNC will be your most trusted partner. As the saying goes, “If you want to do a good job, you have to sharpen the tool first.” In the world of precision manufacturing, CNC is undoubtedly the best choice for you. Choice means choosing the perfect combination of reliability and innovation.