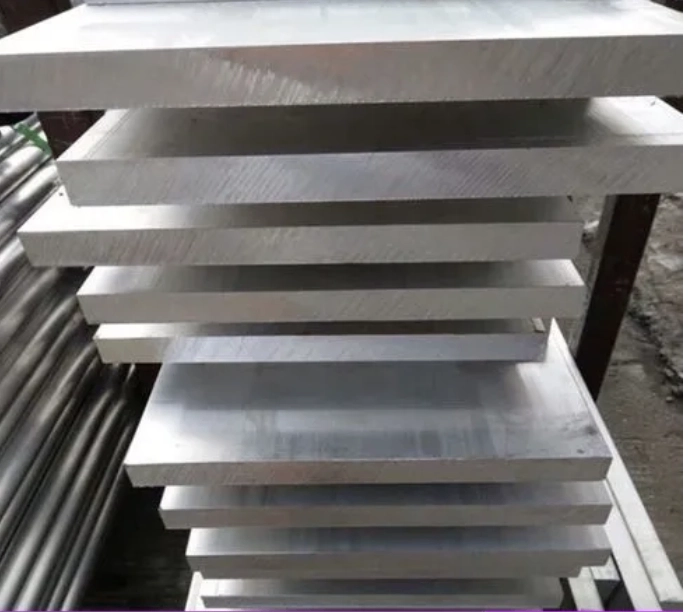

6061 aluminum alloy Material for cnc cutting in cnc factory

Basic introduction

6061 aluminum alloy is made ofHeat treatmentHigh quality produced by pre-stretching processAluminium alloysPRODUCTS.

6061 aluminum is a heat-treated reinforced alloy with good formability, weldability, and machinability. It also has medium strength and can still maintain good operability after annealing. The main alloying elements of 6061 aluminum are magnesium and silicon, and form the Mg2Si phase. If it contains a certain amount of manganese and chromium, it can neutralize the bad effect of iron; sometimes a small amount of copper or zinc is added to improve the strength of the alloy without significantly reducing its corrosion resistance; there is also a small amount of copper in the conductive material, to offset the adverse effects of titanium and iron on conductivity; zirconium or titanium can refine the grains and control the recrystallization structure; To improve the cutability, lead with bismuth may be added. Mg2 Si is solidly soluble in aluminum with cnc cutting in cnc factory, so that the alloy has artificial aging hardening function.

Mechanical properties

The ultimate tensile strength of 6061 is more than 205 MPa

Compressed yield strength 55.2 MPa

Elasticity coefficient 68.9 GPa

Bending limit strength 228 MPa

Bending Yield Strength 103 MPa

Heat treatment

Craft

Quick annealing: Heating temperature 350~410℃; depending on the effective thickness of the material, the insulation time is between 30~120min; air or water cooling. 2 High temperature annealing: When the heating temperature is 350~500℃; when the finished product thickness is ≥6mm, the insulation time is 10~30min. When it is less than 6mm, it will be soaked until it is hot; the air will be cold. 3 Low temperature annealing: heating temperature 150~250℃; insulation time 2~3h; air or water cooling. Homogenization: 570 degrees Celsius, keep warm for 7 hours, air-cooled.

Warm reminder that the density of 6061 aluminum alloy is 2800kg/m^3