Discover the Excellence of the Top CNC Milling Manufacturer: Precision Machining with a Focus on Oscillator Tube Production and Overcoming the Challenges of Rough Milling

Introduction to the Top CNC Milling Manufacturer

History and Background

The top CNC milling manufacturer has a rich and storied history. It all began several decades ago when a group of visionary engineers and machinists came together with a shared passion for precision manufacturing. They recognized the potential of CNC milling technology and set out to establish a company that would revolutionize the industry. Over the years, through continuous innovation and a commitment to quality, the manufacturer has grown into a global leader in CNC milling solutions.

Technological Advancements

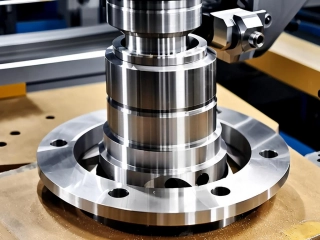

This manufacturer has always been at the forefront of technological advancements. They invest heavily in research and development to ensure that their CNC milling machines are equipped with the latest features and capabilities. From advanced control systems that offer unparalleled precision to high-speed spindles that enable faster and more efficient milling operations, their machines are designed to meet the most demanding manufacturing requirements. For example, their use of cutting-edge software allows for complex geometries to be machined with utmost accuracy, making them ideal for producing components like oscillator tubes.

Quality Assurance

Quality is of utmost importance to the top CNC milling manufacturer. They have implemented a rigorous quality assurance program that covers every aspect of the manufacturing process. From the selection of raw materials to the final inspection of the finished products, strict quality controls are in place to ensure that only the highest quality components are delivered to customers. This commitment to quality has earned them a reputation for reliability and excellence in the industry.

The Significance of Oscillator Tubes

Function and Applications

Oscillator tubes play a crucial role in a wide range of electronic devices. They are responsible for generating and maintaining stable oscillations, which are essential for the proper functioning of circuits such as those found in radios, televisions, and communication systems. In addition to their use in consumer electronics, oscillator tubes are also widely used in industrial and scientific applications, where their high precision and stability are critical. For instance, in medical equipment like MRI machines, oscillator tubes ensure accurate signal generation for precise imaging.

Manufacturing Challenges

Manufacturing oscillator tubes presents several unique challenges. The precision required to produce these components is extremely high, as even the slightest deviation can affect their performance. CNC milling is often the preferred method for manufacturing oscillator tubes due to its ability to achieve the necessary precision. However, the complex geometries and tight tolerances involved make the milling process difficult. The top CNC milling manufacturer has developed specialized techniques and processes to overcome these challenges and produce oscillator tubes of the highest quality.

Dealing with Rough Milling Issues

Causes of Rough Milling

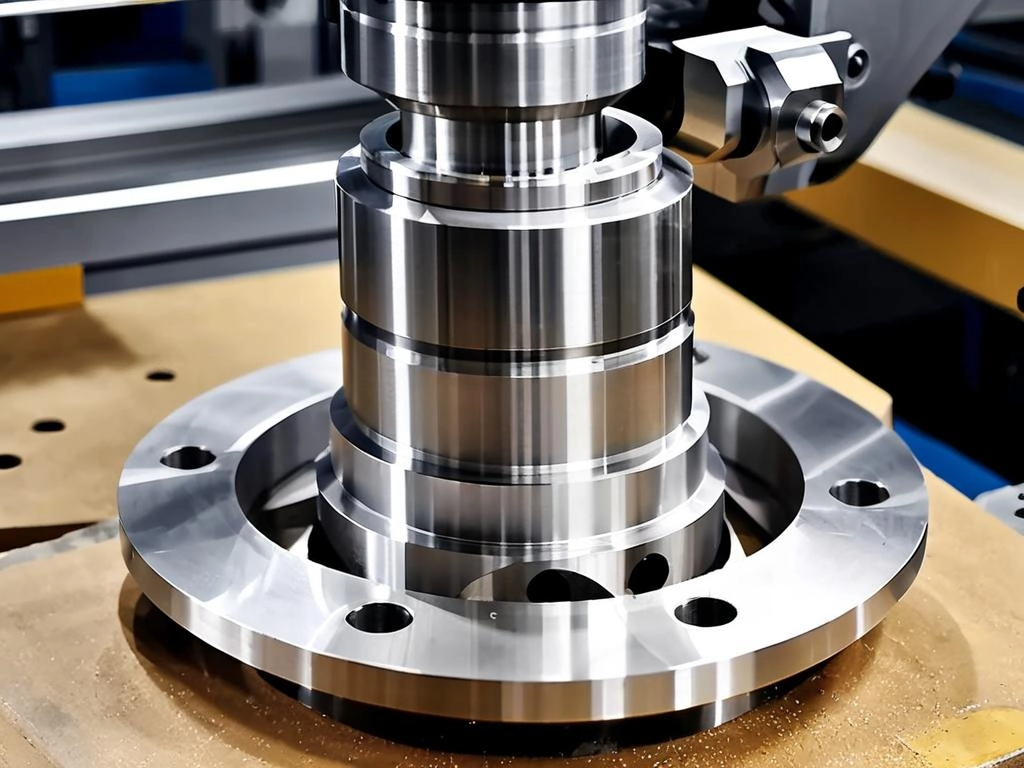

Rough milling can occur due to a variety of reasons. One of the main causes is improper tool selection. Using the wrong type or size of cutting tool can lead to uneven cutting and a rough surface finish. Another factor is incorrect cutting parameters, such as feed rate and spindle speed. If these parameters are not set correctly, it can result in excessive tool wear and a poor surface quality. Additionally, issues with the workpiece material, such as hardness variations, can also contribute to rough milling.

Solutions for Rough Milling

To address the problem of rough milling, the top CNC milling manufacturer employs several strategies. First and foremost, they carefully select the appropriate cutting tools based on the material and geometry of the workpiece. They also optimize the cutting parameters through extensive testing and analysis to ensure the best possible surface finish. In addition, they use advanced coolant systems to reduce heat generation during milling, which helps to prevent tool wear and improve the quality of the machined surface. Another approach is to use multi-step milling processes, where roughing and finishing operations are separated to achieve a smoother final surface.

Benefits of Overcoming Rough Milling

Overcoming rough milling issues offers numerous benefits. A smooth surface finish not only improves the aesthetic appearance of the machined parts but also enhances their functionality. For example, in the case of oscillator tubes, a smooth surface reduces electrical losses and improves the overall performance of the device. It also increases the durability of the components, as rough surfaces are more prone to wear and corrosion. By ensuring a high-quality surface finish, the top CNC milling manufacturer can provide customers with products that meet the highest standards of performance and reliability.

Conclusion

In conclusion, the top CNC milling manufacturer has established itself as a leader in the industry through its commitment to excellence, technological innovation, and quality assurance. Their expertise in manufacturing oscillator tubes and ability to overcome the challenges of rough milling set them apart from the competition. As the demand for high-precision components continues to grow, this manufacturer is well-positioned to meet the needs of customers across a wide range of industries. With their continued focus on improvement and innovation, we can expect to see even more remarkable achievements in the future.