Exploring the Excellence of CNC Titanium Products with a Focus on Vehicle Hinges and the Significance of Plane Measurement

Introduction to CNC Titanium Products

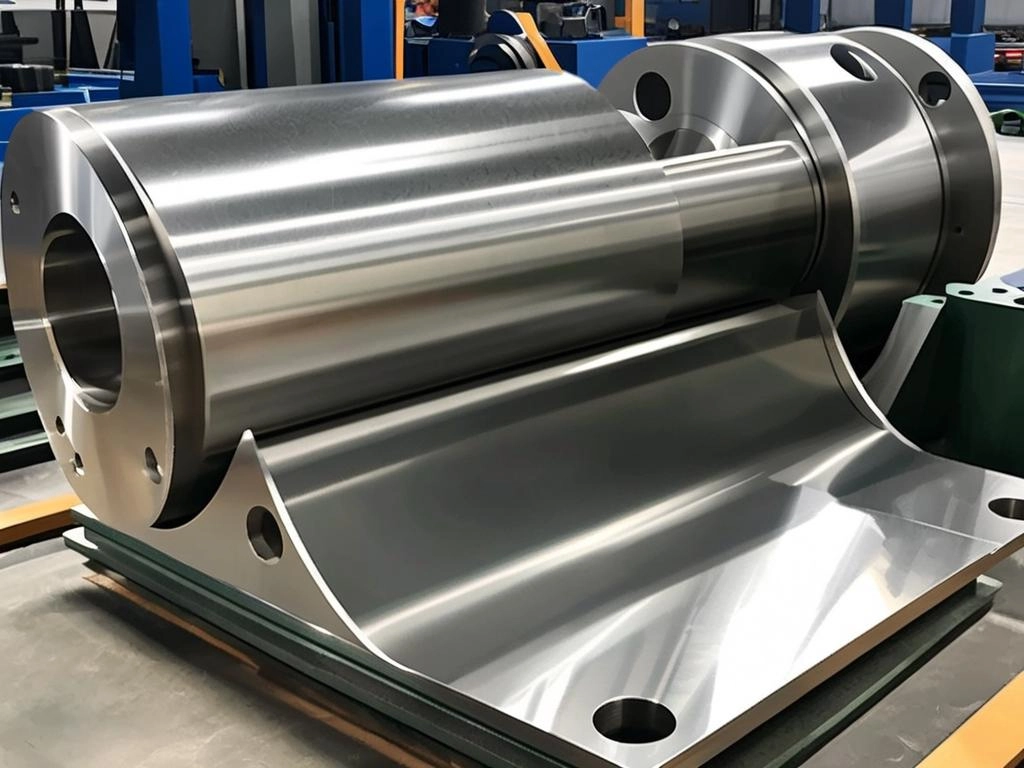

CNC Titanium products have revolutionized various industries with their exceptional properties and precision engineering. Titanium, known for its high strength-to-weight ratio, corrosion resistance, and biocompatibility, is a favored material in many applications. The use of Computer Numerical Control (CNC) technology in manufacturing titanium products ensures utmost accuracy and consistency. CNC machining allows for complex designs and tight tolerances, making it possible to create intricate components that meet the demanding requirements of modern engineering.

Advantages of Titanium in CNC Manufacturing

Titanium's unique combination of properties offers several advantages in CNC manufacturing. Its lightweight nature makes it ideal for applications where weight reduction is crucial, such as in the aerospace and automotive industries. Additionally, its corrosion resistance ensures longevity and reliability, even in harsh environments. CNC Titanium products can withstand extreme temperatures and pressures, making them suitable for use in high-performance applications. For example, in the production of vehicle hinges, titanium's strength and durability provide a stable and long-lasting connection.

Precision and Complexity Achieved with CNC Technology

CNC technology enables the creation of highly precise and complex titanium products. The computer-controlled machining process can accurately reproduce intricate designs with minimal error. This level of precision is essential for components like vehicle hinges, where a perfect fit and smooth operation are required. CNC machines can work with titanium to create parts with tight tolerances, ensuring that each hinge functions flawlessly and provides the necessary support and movement for vehicle doors and other components.

Vehicle Hinges: A Critical Component

Vehicle hinges play a vital role in the functionality and safety of automobiles. They are responsible for the smooth opening and closing of doors, hoods, and trunks. A high-quality vehicle hinge must be able to withstand constant use, exposure to the elements, and the forces exerted during normal operation. CNC Titanium vehicle hinges offer superior performance compared to traditional hinges made from other materials.

Enhanced Durability and Strength

The use of titanium in vehicle hinges provides enhanced durability and strength. Titanium's high tensile strength allows the hinges to bear heavy loads without deforming or breaking. This is particularly important for larger and heavier vehicle doors. The corrosion resistance of titanium ensures that the hinges remain in good condition even after years of exposure to rain, snow, and road salt. This extends the lifespan of the hinges and reduces the need for frequent replacements.

Smooth Operation and Reduced Friction

CNC Titanium vehicle hinges are designed to offer smooth operation with minimal friction. The precision machining of titanium components results in a smooth surface finish, reducing the resistance between the hinge parts. This allows for effortless opening and closing of vehicle doors and other components. The reduced friction also helps to prevent wear and tear, further enhancing the longevity of the hinges.

Design Flexibility for Custom Applications

CNC technology allows for great design flexibility when it comes to vehicle hinges. Manufacturers can create custom-designed hinges to meet the specific requirements of different vehicle models. Whether it's a unique door design or a special hinge mechanism, CNC Titanium hinges can be tailored to fit the exact needs of the application. This design flexibility enables automotive engineers to innovate and create more advanced and user-friendly vehicle designs.

The Significance of Plane Measurement

Plane measurement is a crucial aspect in the manufacturing of CNC Titanium products, especially when it comes to components like vehicle hinges. Accurate plane measurement ensures that the surfaces of the titanium parts are flat and parallel, which is essential for proper fit and function. Any deviations in plane measurement can lead to misalignment, increased friction, and reduced performance of the hinges.

Ensuring Proper Alignment and Fit

Precise plane measurement guarantees that the mating surfaces of the vehicle hinge components are perfectly aligned. This ensures a tight and secure fit, preventing any play or movement that could affect the stability and operation of the hinge. When the planes are accurately measured and machined, the hinge can function smoothly and reliably, providing a consistent and predictable performance over its lifespan.

Quality Control and Consistency

Plane measurement is an important part of the quality control process in CNC Titanium manufacturing. By accurately measuring the planes of each titanium part, manufacturers can ensure that all components meet the required specifications and standards. This helps to maintain consistency in the production process, resulting in high-quality vehicle hinges that perform uniformly. Consistent plane measurement also allows for easier assembly and integration of the hinges into the vehicle, reducing production time and costs.

Optimizing Performance and Efficiency

Accurate plane measurement contributes to the overall performance and efficiency of CNC Titanium vehicle hinges. When the planes are precisely machined, the hinge can operate with minimal energy loss due to friction. This not only improves the user experience by making the doors and other components easier to open and close but also reduces the strain on the vehicle's power systems. Additionally, proper plane measurement helps to optimize the load distribution across the hinge, increasing its load-bearing capacity and further enhancing its durability.

In conclusion, CNC Titanium products, particularly vehicle hinges, offer a combination of strength, durability, and precision that is unmatched by traditional materials and manufacturing methods. The use of CNC technology allows for the creation of complex and high-quality titanium components, while accurate plane measurement ensures their proper fit and function. As the automotive industry continues to evolve and demand higher performance and reliability, CNC Titanium vehicle hinges will play an increasingly important role in meeting these requirements. Manufacturers and engineers must continue to focus on optimizing the manufacturing process, including precise plane measurement, to ensure the continued success and innovation of these critical components.