CNC Machining company search: Finding the Right Partner for Precision Front Axle Housing Production Amid the Challenge of Parameter Mis-setting

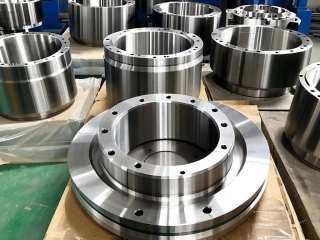

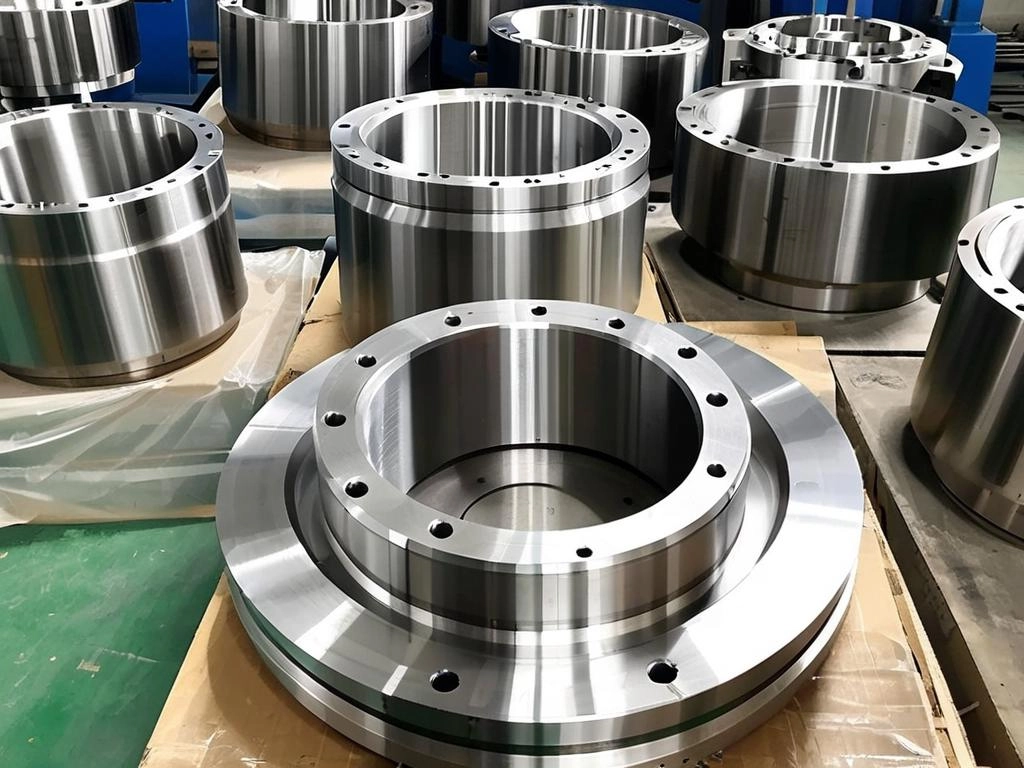

Importance of CNC Machining for Front Axle Housing

CNC machining plays a crucial role in the manufacturing of front axle housings. The front axle housing is a vital component in vehicles, providing support and protection to various mechanical parts. It needs to be precisely machined to ensure proper fit, strength, and durability. CNC machining offers high precision and accuracy, allowing for the creation of complex shapes and tight tolerances required for front axle housings. With computer-controlled operations, CNC machines can consistently produce high-quality parts, meeting the strict standards of the automotive industry.

Precision Engineering in Front Axle Housing Machining

To achieve the desired precision in front axle housing machining, CNC machining companies need to have advanced equipment and highly skilled operators. The machining process involves multiple steps, including cutting, drilling, milling, and grinding. Each step requires careful planning and execution to ensure that the final product meets the specifications. For example, the dimensions of the housing must be accurate to ensure proper alignment of the axle and other components. Any deviation from the specified dimensions can lead to problems such as vibrations, noise, and premature wear.

Material Selection for Front Axle Housings

The choice of material for front axle housings is also critical. Common materials used include steel, aluminum, and cast iron. Each material has its own advantages and disadvantages in terms of strength, weight, and cost. Steel is known for its high strength and durability, making it suitable for heavy-duty applications. Aluminum, on the other hand, is lighter in weight, which can improve fuel efficiency. Cast iron is often used for its excellent casting properties and ability to absorb vibrations. CNC machining companies need to consider these factors when selecting the appropriate material for front axle housing production.

Quality Control in CNC Machining

Quality control is an essential aspect of CNC machining for front axle housings. Machining companies need to implement strict quality control measures to ensure that the produced parts meet the required standards. This includes regular inspection of the machining process, measurement of dimensions, and testing of the mechanical properties of the parts. Any defects or deviations from the specifications should be identified and corrected promptly to avoid costly rework or product failures.

Challenges of Parameter Mis-setting in CNC Machining

One of the significant challenges faced by CNC machining companies is parameter mis-setting. Incorrectly set parameters can lead to various problems, such as inaccurate dimensions, poor surface finish, and tool wear. Parameter mis-setting can occur due to human error, lack of proper training, or incorrect programming. For example, if the cutting speed and feed rate are not set correctly, it can result in excessive tool wear and poor surface quality of the machined part.

Effects of Parameter Mis-setting on Front Axle Housing Quality

In the case of front axle housing machining, parameter mis-setting can have serious consequences. Incorrect parameters can lead to dimensional inaccuracies, which can affect the fit and function of the housing. This can result in problems such as misalignment of the axle, increased friction, and reduced vehicle performance. Additionally, poor surface finish due to parameter mis-setting can lead to corrosion and fatigue failure of the housing over time.

Preventing Parameter Mis-setting in CNC Machining

To prevent parameter mis-setting, CNC machining companies need to invest in proper training for their operators. Operators should have a thorough understanding of the machining process and the parameters involved. They should also be trained to follow standard operating procedures and perform regular checks to ensure that the parameters are set correctly. Additionally, the use of advanced programming software and simulation tools can help in optimizing the machining parameters and detecting any potential errors before actual machining.

Searching for the Right CNC Machining Company for Front Axle Housing Production

When searching for a CNC machining company for front axle housing production, several factors need to be considered. Firstly, the company should have extensive experience in machining front axle housings and a proven track record of delivering high-quality products. They should also have advanced CNC machining equipment and a team of skilled operators and engineers. Secondly, the company should have a strong quality control system in place to ensure that the produced parts meet the required standards.

Evaluating the Capabilities of CNC Machining Companies

To evaluate the capabilities of CNC machining companies, it is essential to visit their facilities and assess their equipment and processes. Look for companies that have invested in the latest CNC machining technology and have a clean and organized production environment. Additionally, ask for samples of their previous work and check the quality of the machined parts. You can also inquire about their quality control procedures and certifications to ensure that they meet industry standards.

Cost Considerations in CNC Machining

Cost is another important factor to consider when choosing a CNC machining company. While it is important to find a company that offers competitive prices, it is equally important to ensure that the quality of the parts is not compromised. Look for companies that offer a balance between cost and quality and can provide cost-effective solutions for your front axle housing production needs.

Communication and Customer Service

Good communication and customer service are also crucial when working with a CNC machining company. The company should be able to understand your requirements clearly and provide timely updates on the progress of your order. They should also be responsive to any queries or concerns you may have and be willing to work with you to address any issues that arise during the production process.

In conclusion, finding the right CNC machining company for front axle housing production requires careful consideration of various factors. By understanding the importance of CNC machining, the challenges of parameter mis-setting, and the key factors to consider when searching for a machining company, you can make an informed decision and ensure the successful production of high-quality front axle housings.