New Energy CNC Turning for Analog Radio Case: An In-depth Look at the Process, Quality, and Price Considerations

Introduction to New Energy CNC Turning

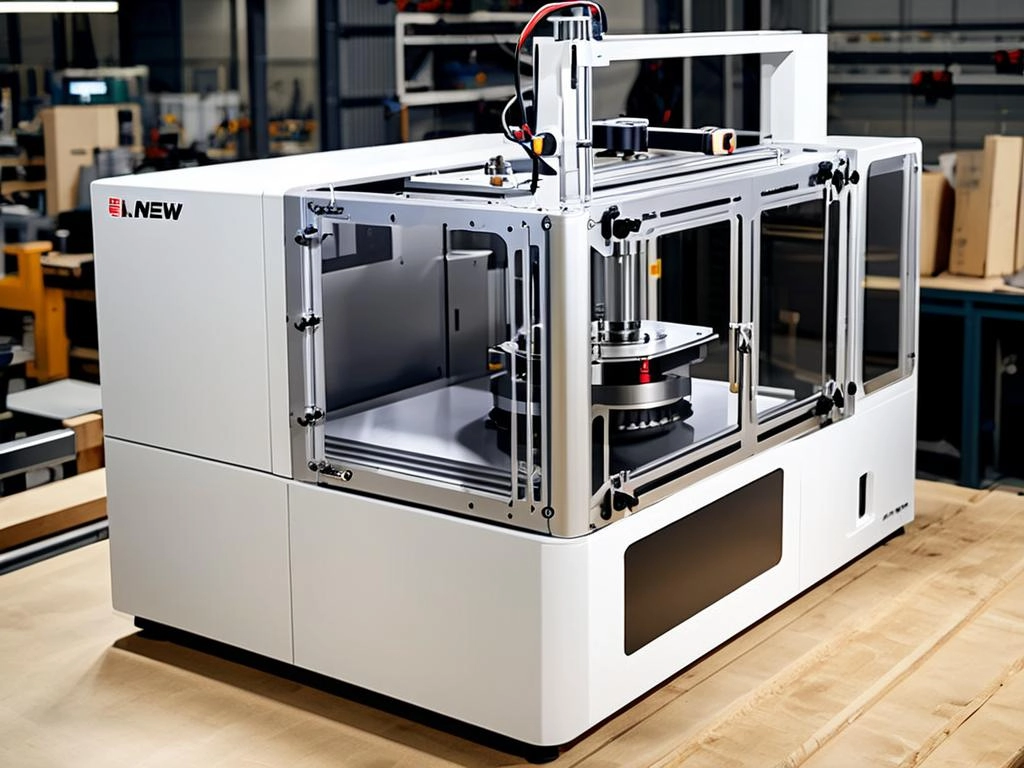

The Concept of New Energy CNC Turning

New Energy CNC Turning represents a revolutionary approach in the manufacturing industry. It combines the precision and efficiency of Computer Numerical Control (CNC) technology with the utilization of new energy sources. This innovative method has significantly enhanced the production process, allowing for greater accuracy, faster production times, and reduced environmental impact. In the context of manufacturing analog radio cases, New Energy CNC Turning plays a crucial role in ensuring the highest quality and functionality.

Advantages of New Energy CNC Turning

One of the primary advantages of New Energy CNC Turning is its ability to achieve extremely high levels of precision. The computer-controlled machinery can execute complex designs with minimal error, resulting in analog radio cases that fit together perfectly and function flawlessly. Additionally, the use of new energy sources reduces the carbon footprint of the manufacturing process, making it more sustainable and environmentally friendly. This is an important consideration in today's world, where consumers are increasingly conscious of the environmental impact of the products they purchase.

The Significance of Analog Radio Cases

Functionality of Analog Radio Cases

Analog radio cases serve a vital function in protecting the internal components of the radio. They provide a sturdy and durable enclosure that shields the delicate electronics from damage due to physical impact, moisture, and dust. Moreover, the design of the case can also impact the performance of the radio. A well-designed case can improve the antenna reception and sound quality, enhancing the overall user experience.

Design Considerations for Analog Radio Cases

When it comes to designing analog radio cases, several factors need to be taken into account. The case must be aesthetically pleasing, as it is often the first thing that consumers notice. It should also be ergonomically designed, with easy-to-access controls and a comfortable grip. In addition, the material used for the case should be of high quality, able to withstand the rigors of daily use. New Energy CNC Turning allows for the creation of intricate and detailed designs, enabling manufacturers to produce analog radio cases that are both functional and visually appealing.

Price Analysis of New Energy CNC Turned Analog Radio Cases

Factors Affecting the Price

The price of New Energy CNC turned analog radio cases can vary depending on several factors. The complexity of the design is a significant determinant. More intricate designs require more time and resources to produce, which can drive up the cost. The material used also plays a role. High-quality materials such as metal or premium plastics will generally cost more than lower-quality alternatives. Additionally, the volume of production can impact the price. Larger production runs often result in lower unit costs due to economies of scale.

Comparing Prices with Traditional Manufacturing Methods

When compared to traditional manufacturing methods, New Energy CNC Turning may initially seem more expensive. However, it is important to consider the long-term benefits. The precision and efficiency of CNC turning can reduce waste and rework, ultimately saving costs in the long run. Moreover, the higher quality of the finished products can lead to increased customer satisfaction and loyalty, which can have a positive impact on the bottom line.

Value for Money in New Energy CNC Turned Analog Radio Cases

Despite the potentially higher price tag, New Energy CNC turned analog radio cases offer excellent value for money. The superior quality and performance of these cases make them a worthwhile investment. They provide better protection for the radio components, resulting in a longer lifespan for the device. Additionally, the aesthetic appeal of the cases can enhance the brand image and attract more customers, making them a valuable asset for manufacturers.

Conclusion

In conclusion, New Energy CNC Turning has revolutionized the manufacturing of analog radio cases. It offers numerous advantages in terms of precision, efficiency, and environmental sustainability. The significance of analog radio cases cannot be overstated, as they play a crucial role in protecting and enhancing the performance of the radio. While the price of New Energy CNC turned analog radio cases may be higher in some cases, the value they provide in terms of quality and performance makes them a wise choice for both manufacturers and consumers. As technology continues to advance, we can expect further improvements in New Energy CNC Turning, leading to even better analog radio cases in the future.