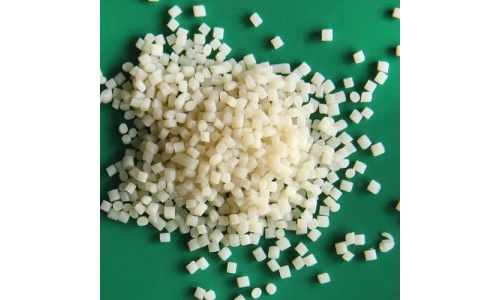

Saigang-POM material used in cnc manufacturing

Basic Introduction

Also known as polyoxymethylene. The structure is, and the English abbreviation is POM material used in cnc manufacturing. Usually, the polymer obtained by polymerization of formaldehyde has a low degree of polymerization and is easily depolymerized by heat. Around DuPont obtained formaldehyde homopolymer by polymerization of formaldehyde. Polyoxymethylene is easy to crystallize, with a crystallinity of more than 70%. The melting temperature of homopolyoxymethylene is about 180℃.

Mechanical properties

Density 1.45g/cm3 Volume resistivity VD0303 ≥1015xcm

Water absorption 0.8% Surface resistance VDE0303 ≥1013

Chemical resistance - Dielectric constant 1MHz DIN53483 3.8

Continuous use temperature -50~90℃ Dielectric loss factor 1MHz DIN53483 0.005

Yield tensile strength 62MPa Dielectric strength VDE0303 85kv/mm

Yield tensile strain 10% Leakage current strength DIN5340 KC600

Ultimate tensile strength﹣ Adhesion﹢

Ultimate tensile strain 40% Non-toxic and harmless EEC90/128 ﹢

Impact toughness 0.B.kJ/m2 Friction coefficient DIN53375 0.35

Notched impact toughness 7kJ/m2 Combustion performance UL94 HB

Rockwell ball pressure hardness 135MPa UV resistance UV 0

Shore D hardness 85 Acid resistance﹢

Flexural strength﹣ Alkali resistance﹢

Elastic modulus 2600MPa Carbonated water resistance﹢

Vicat softening temperature 150℃ Chlorocarbonic acid water resistance (CKW) 0

Heat distortion temperature﹣ Aromatic compound resistance﹢

Thermal linear expansion coefficient 1.1k-1*104 Ketone resistance ﹢

Thermal conductivity 20℃ 0.31w/(mxk) Hot water resistance﹢

Heat Treatment

Methods

Drying: Drying is usually not required if the material is stored in a dry environment.

Melting temperature: 190~230℃ for homopolymer materials; 190~210℃ for copolymer materials.

Mold temperature: 80~105℃. In order to reduce the shrinkage after molding, a higher mold temperature can be selected. Injection pressure: 700~1200bar.

Injection speed: medium to fast. Too slow will easily produce ripples, too fast will easily produce jetting and shear overheating.

Runners and gates: Any type of gate can be used. If a tunnel gate is used, a shorter type is preferred. Hot injection molding is recommended for homopolymer materials.

For copolymer materials, both internal and external hot runners can be used.

Back pressure: The lower the better, generally not exceeding 200 bar

Residence time: If the equipment does not have a melt retention point, POM-H can be retained at 215℃ for 35 minutes; POM-K can be retained at 205℃ for 20 minutes without serious decomposition.

At the injection temperature, the melt cannot stay in the barrel for more than 20 minutes. POM-K can stay in the barrel for 7 minutes at 240°C. If the machine is shut down, the barrel temperature can be reduced to 150°C. If the machine is shut down for a long time, the barrel must be cleaned and the heater must be turned off.

Stop: Use PE or PP to clean the barrel, turn off the electric heat, and push the screw to the front position. The barrel and screw must be kept clean. Impurities or dirt will change the overheating stability of POM (especially POM-H). Therefore, after using halogen-containing polymers or other acidic polymers, PE should be used to clean it before punching POM materials, otherwise it will explode. Improper use of pigments, lubricants or materials containing GF nylon will cause plastic degradation.

Processing

Post-processing: For parts that are used at very low temperatures and have high quality requirements, heat treatment is required.

Annealing treatment effect: the product can be immersed in a 30% hydrochloric acid solution for 30 minutes for inspection, and then observed with the naked eye to determine whether there are residual stress cracks.