Unveiling the Excellence of Top CNC Prototyping Manufacturer Amid Market Fluctuations with Nylon PA66 - GF30

Introduction to CNC Prototyping

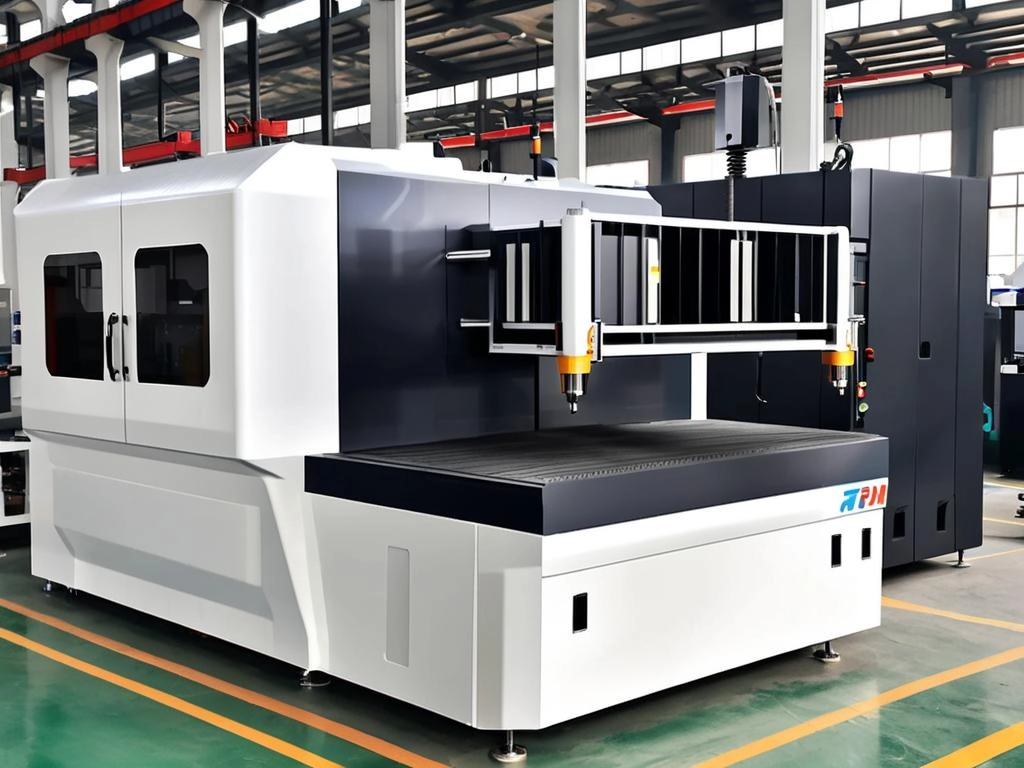

CNC (Computer Numerical Control) prototyping has revolutionized the product development process across various industries. It offers a precise and efficient way to create prototypes that closely mimic the final product in terms of form, fit, and function. A top CNC prototyping manufacturer is a key partner for companies looking to bring their innovative ideas to life. These manufacturers utilize advanced CNC machines and skilled technicians to transform digital designs into physical prototypes with high accuracy.

The process involves translating 3D CAD models into machine-readable code. The CNC machine then follows these instructions to cut, shape, and finish the prototype from a variety of materials. This technology has significantly reduced the time and cost associated with traditional prototyping methods, allowing for faster iterations and better product development cycles.

The Role of a Top CNC Prototyping Manufacturer

A top CNC prototyping manufacturer stands out for several reasons. Firstly, they have a team of experienced engineers and designers who can provide valuable insights during the prototyping process. They can help optimize the design for manufacturability, ensuring that the final product can be mass-produced efficiently.

Secondly, these manufacturers invest in state-of-the-art CNC equipment. This includes multi-axis milling machines, lathes, and routers that can handle complex geometries with ease. The precision of these machines is crucial for creating prototypes that meet the exact specifications of the design.

Moreover, a top manufacturer has a quality control system in place. They conduct thorough inspections at every stage of the prototyping process to ensure that the final product is of the highest quality. This attention to detail helps in identifying and rectifying any potential issues early on, saving both time and resources.

Importance in Different Industries

In the automotive industry, CNC prototyping is used to create parts such as engine components, interior fixtures, and exterior body panels. The ability to quickly produce accurate prototypes allows automakers to test new designs and technologies before mass production. This helps in reducing development time and improving the overall quality of the vehicle.

The aerospace industry also relies heavily on CNC prototyping. Components for aircraft, such as turbine blades and structural parts, require high precision and quality. A top CNC prototyping manufacturer can meet these stringent requirements, enabling aerospace companies to innovate and develop advanced aircraft designs.

In the consumer electronics sector, CNC prototyping is used to create sleek and functional product enclosures. The ability to quickly produce prototypes helps electronics companies stay ahead in the competitive market by bringing new products to market faster.

Nylon PA66 - GF30: A Preferred Material for CNC Prototyping

Nylon PA66 - GF30 is a popular material choice for CNC prototyping. It is a composite material made up of Nylon 66 resin reinforced with 30% glass fiber. This combination offers a unique set of properties that make it ideal for a wide range of applications.

The addition of glass fiber significantly enhances the mechanical properties of Nylon 66. It increases the strength, stiffness, and dimensional stability of the material. This makes Nylon PA66 - GF30 suitable for creating prototypes that need to withstand high mechanical stresses.

Mechanical Properties

Nylon PA66 - GF30 has a high tensile strength, which means it can resist being pulled apart under stress. This property is crucial for components that are subjected to forces in real-world applications. For example, in automotive parts, such as gears and brackets, the high tensile strength of Nylon PA66 - GF30 ensures reliable performance.

The stiffness of the material also makes it suitable for applications where dimensional accuracy is important. It reduces the amount of deflection under load, ensuring that the prototype maintains its shape and form. This is especially important for parts that need to fit precisely with other components.

Thermal Properties

Nylon PA66 - GF30 has good thermal stability. It can withstand high temperatures without significant degradation of its mechanical properties. This makes it suitable for applications where the prototype may be exposed to heat, such as in engine compartments or industrial equipment.

The material also has a relatively low coefficient of thermal expansion. This means that it does not expand or contract significantly with changes in temperature. This property helps in maintaining the dimensional accuracy of the prototype over a wide range of temperatures.

Chemical Resistance

Nylon PA66 - GF30 offers good chemical resistance. It can withstand exposure to various chemicals, including oils, fuels, and many common solvents. This makes it suitable for applications in industries where the prototype may come into contact with chemicals, such as in the automotive and chemical processing industries.

Navigating Market Fluctuations as a CNC Prototyping Manufacturer

The business of CNC prototyping is not without its challenges, especially in the face of market fluctuations. These fluctuations can be caused by various factors, such as changes in raw material prices, economic conditions, and shifts in customer demand.

Raw material prices, in particular, can have a significant impact on the cost of CNC prototyping. Fluctuations in the price of materials like Nylon PA66 - GF30 can affect the profitability of a prototyping project. A top CNC prototyping manufacturer needs to have strategies in place to manage these cost fluctuations.

Supply Chain Management

One way to navigate market fluctuations is through effective supply chain management. A top manufacturer builds strong relationships with multiple suppliers of raw materials. This allows them to source materials from different sources in case of price hikes or shortages from a particular supplier.

They also use inventory management techniques to optimize the stock levels of raw materials. By maintaining an appropriate level of inventory, they can buffer against sudden price increases and ensure a continuous supply of materials for prototyping projects.

Diversification of Services

Another strategy is to diversify the services offered. A top CNC prototyping manufacturer may expand beyond traditional prototyping services to include value-added services such as product design assistance, finishing services, and even small-scale production runs. This diversification helps in reducing the dependence on a single source of revenue and makes the business more resilient to market fluctuations.

Customer-Centric Approach

Maintaining a customer-centric approach is also crucial. A top manufacturer understands the needs and challenges of its customers in the face of market fluctuations. They work closely with customers to develop cost-effective prototyping solutions that meet their requirements. This includes providing flexible pricing options and delivery schedules.

Case Studies: Success Stories of a Top CNC Prototyping Manufacturer with Nylon PA66 - GF30

Let's take a look at some real-world examples of how a top CNC prototyping manufacturer has utilized Nylon PA66 - GF30 to overcome challenges and achieve success in the face of market fluctuations.

Automotive Industry Case

A leading automotive company was developing a new engine component. They needed a prototype that could withstand high temperatures and mechanical stresses. A top CNC prototyping manufacturer recommended Nylon PA66 - GF30 for its excellent mechanical and thermal properties.

Despite market fluctuations in the price of raw materials, the manufacturer was able to source the Nylon PA66 - GF30 at a reasonable cost through its strong supply chain relationships. The prototyping process was completed within the specified time frame, and the automotive company was able to test the component thoroughly before moving to mass production. This helped the automotive company save time and money in the product development process.

Aerospace Industry Case

An aerospace firm was working on a new aircraft interior component. They required a prototype that was lightweight yet strong and had good dimensional stability. The top CNC prototyping manufacturer used Nylon PA66 - GF30 to create the prototype.

During the prototyping process, the market experienced a slowdown in the aerospace industry. However, the manufacturer's diversification of services, which included design optimization, helped the aerospace firm improve the design of the component. This not only reduced the weight of the component but also improved its performance. The successful prototype led to a long-term partnership between the two companies.

Consumer Electronics Industry Case

A consumer electronics company was launching a new smartphone. They needed a prototype of the phone's enclosure that had a sleek design and good mechanical properties. The top CNC prototyping manufacturer used Nylon PA66 - GF30 to create the prototype.

With the fast-paced nature of the consumer electronics industry and constant market fluctuations in terms of demand and competition, the manufacturer's customer-centric approach came into play. They worked closely with the electronics company to meet their tight deadlines and provided cost-effective solutions. The prototype was well-received, and it helped the electronics company gain a competitive edge in the market.

Conclusion

In conclusion, a top CNC prototyping manufacturer plays a vital role in the product development process. When combined with a high-quality material like Nylon PA66 - GF30, they can create prototypes that meet the most demanding requirements of various industries.

Navigating market fluctuations is an ongoing challenge, but with effective strategies such as supply chain management, diversification of services, and a customer-centric approach, these manufacturers can not only survive but thrive in a dynamic market environment.

As the industries continue to evolve and demand more innovative products, the importance of top CNC prototyping manufacturers using materials like Nylon PA66 - GF30 will only increase. They will be at the forefront of driving product development and innovation, helping companies bring their ideas to market faster and more efficiently.