Unveiling the Excellence of CNC POM in Pivot Shaft Applications and the Significance of System Linkage Adjustment

0.00

SKU:CNCS0054

Mpn:CNCM0054

Category:Machining Parts

* The data is open source, not security confidential file from client.

Introduction to CNC POM

What is CNC POM?

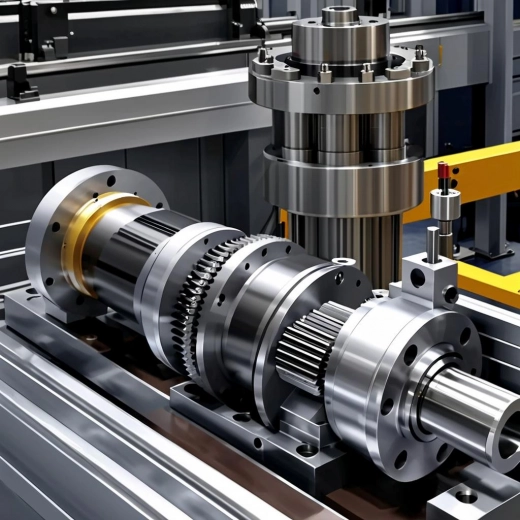

CNC POM, which stands for Computer Numerical Control Polyoxymethylene, is a remarkable material that has found extensive applications in various industries. POM is a thermoplastic polymer known for its excellent mechanical properties, such as high strength, stiffness, and low friction coefficient. When combined with the precision of CNC machining, CNC POM components offer unparalleled accuracy and reliability.

Properties of CNC POM

The properties of CNC POM make it an ideal choice for many applications. It has excellent dimensional stability, meaning that it retains its shape and size even under varying environmental conditions. This is crucial in applications where precision is of utmost importance, such as in the manufacturing of pivot shafts. Additionally, CNC POM has good chemical resistance, making it suitable for use in harsh chemical environments. Its low moisture absorption rate also ensures consistent performance over time.

The Role of Pivot Shaft

Function of Pivot Shaft

The pivot shaft plays a vital role in many mechanical systems. It serves as a central axis around which other components rotate or pivot. In applications such as robotics, automotive suspensions, and industrial machinery, the pivot shaft provides the necessary support and smooth movement for the connected parts. For example, in a robotic arm, the pivot shaft allows for precise and flexible movement, enabling the arm to perform complex tasks with accuracy.

Importance of Precision in Pivot Shafts

Precision is key when it comes to pivot shafts. Even the slightest deviation in the shaft's dimensions or alignment can lead to significant problems, such as increased wear and tear, reduced efficiency, and inaccurate movement. CNC POM pivot shafts offer the required precision, as the CNC machining process ensures tight tolerances and smooth surface finishes. This results in improved performance and longer service life of the mechanical systems in which they are used.

System Linkage Adjustment

Understanding System Linkage

System linkage refers to the connection and interaction between different components within a mechanical system. It is essential for the proper functioning of the system as a whole. In many cases, the pivot shaft is an integral part of the system linkage, as it connects various moving parts and enables the transfer of motion and force. For example, in a conveyor belt system, the pivot shafts help in guiding and aligning the belts, ensuring smooth and efficient material transfer.

The Need for Adjustment

Over time, due to factors such as wear, vibration, and changes in operating conditions, the system linkage may require adjustment. This is to maintain the optimal performance of the system. Adjusting the pivot shaft's position, alignment, or tension can help correct any misalignments or irregularities in the system linkage. For instance, in a printing press, regular adjustment of the pivot shafts ensures accurate registration and high-quality printing results.

Methods of System Linkage Adjustment

There are several methods for adjusting system linkage. One common approach is to use adjustable mounts or brackets that allow for fine-tuning of the pivot shaft's position. Another method is to use tensioning devices to adjust the tension in belts or chains connected to the pivot shaft. Additionally, regular inspection and maintenance can help identify any potential issues early on and allow for timely adjustments. By implementing these adjustment methods, the overall performance and reliability of the mechanical system can be significantly improved.

Applications of CNC POM Pivot Shafts with System Linkage Adjustment

Automotive Industry

In the automotive industry, CNC POM pivot shafts with proper system linkage adjustment are used in various components, such as suspension systems and steering mechanisms. The precision and reliability of CNC POM ensure smooth and responsive handling, enhancing the driving experience. The ability to adjust the system linkage also allows for fine-tuning of the vehicle's performance according to different driving conditions.

Industrial Machinery

Industrial machinery often relies on CNC POM pivot shafts for precise movement and operation. With system linkage adjustment, these shafts can be optimized for specific applications, such as in CNC milling machines and automated production lines. The accurate positioning and smooth rotation provided by CNC POM pivot shafts contribute to higher productivity and quality in manufacturing processes.

Robotics

Robotics is another field where CNC POM pivot shafts and system linkage adjustment are crucial. The precise movement and flexibility offered by these components enable robots to perform complex tasks with high accuracy. Whether it's in assembly lines, surgical robots, or exploration robots, the combination of CNC POM pivot shafts and proper system linkage adjustment ensures reliable and efficient operation.

Future Trends and Developments

Advancements in CNC Machining Technology

As CNC machining technology continues to advance, we can expect even greater precision and efficiency in the production of CNC POM pivot shafts. New machining techniques and tools will enable manufacturers to achieve tighter tolerances and more complex geometries, further enhancing the performance of these components.

Smart System Linkage Adjustment

The integration of smart sensors and control systems into mechanical systems will revolutionize system linkage adjustment. These systems will be able to monitor the performance of the pivot shafts and other components in real-time and make automatic adjustments as needed. This will not only improve the efficiency and reliability of the systems but also reduce the need for manual intervention.

New Applications and Markets

With the continuous development of various industries, new applications for CNC POM pivot shafts with system linkage adjustment will emerge. For example, in the field of renewable energy, these components may be used in wind turbines and solar tracking systems. The growing demand for high-performance and reliable mechanical components will drive further innovation and expansion in this area.