Exploring the Intricacies of 4 Axis CNC Machining in Creating Necklaces with a Focus on Precise Dimension Comparison

Introduction to 4 Axis CNC Machining

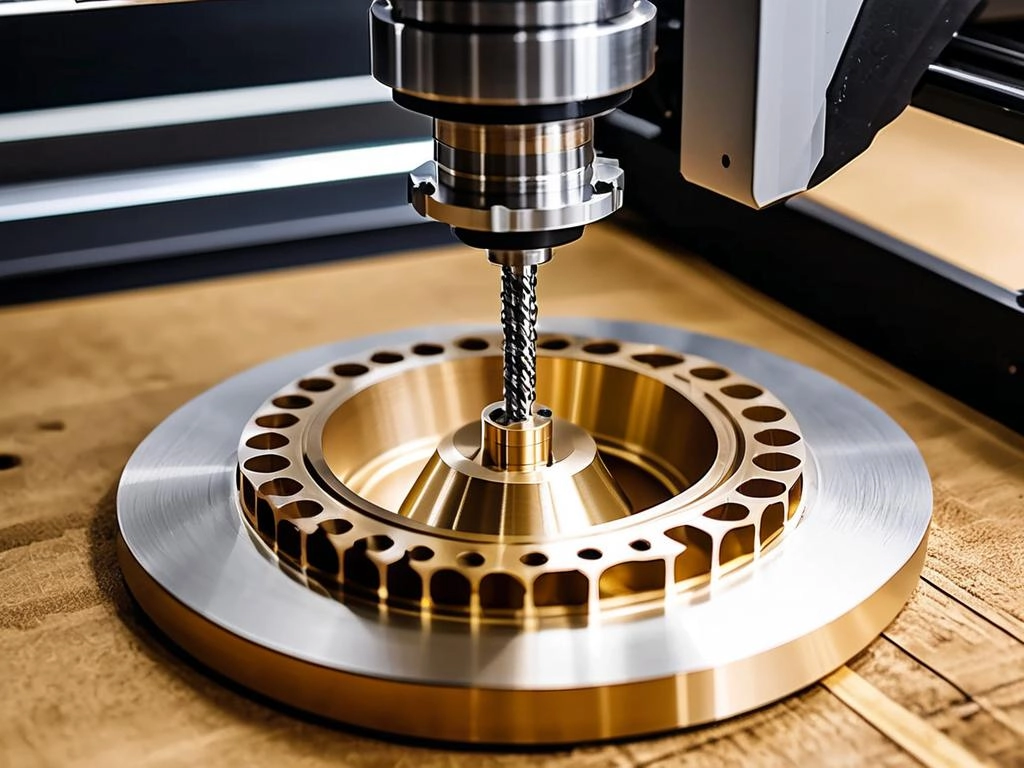

4 Axis CNC Machining has revolutionized the manufacturing industry with its precision and versatility. Unlike traditional machining methods that are often limited in their capabilities, 4 Axis CNC Machining adds an extra dimension of movement, allowing for more complex and intricate designs. This technology is widely used in various fields, including jewelry making. In the context of creating necklaces, 4 Axis CNC Machining offers unparalleled accuracy and efficiency.

The Basics of 4 Axis CNC Machining

At its core, 4 Axis CNC Machining involves the use of computer numerical control (CNC) systems to automate the machining process. The four axes typically refer to the X, Y, and Z axes, which control the movement in the horizontal, vertical, and depth directions respectively. The fourth axis, usually the A-axis, allows for rotational movement around one of the other axes. This additional rotational capability enables the machining tool to approach the workpiece from different angles, resulting in more complex shapes and contours.

Advantages of 4 Axis CNC Machining

One of the significant advantages of 4 Axis CNC Machining is its ability to produce highly precise and consistent parts. The automated nature of the process eliminates human errors and ensures that each piece is machined to the exact specifications. This is crucial when it comes to creating necklaces, where even the slightest deviation in dimensions can affect the overall aesthetic and fit. Additionally, 4 Axis CNC Machining can significantly reduce production time compared to traditional methods, allowing for faster turnaround and increased productivity.

Designing Necklaces with 4 Axis CNC Machining

When it comes to designing necklaces using 4 Axis CNC Machining, the possibilities are endless. Designers can create intricate patterns, unique shapes, and personalized details that would be extremely difficult or impossible to achieve with traditional manufacturing techniques. The precision of the machining process allows for the creation of delicate and complex components that add a touch of elegance to the final piece.

Material Selection for Necklace Machining

The choice of materials is an important aspect of necklace design. Different materials have different properties and characteristics that can affect the machining process and the final outcome. Common materials used in necklace machining include metals such as gold, silver, and platinum, as well as gemstones and other precious materials. Each material requires specific machining parameters and techniques to ensure optimal results. For example, metals may require different cutting speeds and feeds compared to gemstones to avoid damage and achieve a smooth finish.

Customization and Personalization

4 Axis CNC Machining enables a high level of customization and personalization in necklace design. Customers can have their necklaces tailored to their specific preferences, such as choosing the shape, size, and design elements. This level of customization not only satisfies the individual needs of the customers but also adds value to the product. Designers can use the capabilities of 4 Axis CNC Machining to incorporate personalized engravings, initials, or other unique details that make each necklace one-of-a-kind.

The Importance of Dimension Comparison in Necklace Making

Dimension comparison plays a crucial role in ensuring the quality and fit of necklaces. Precise dimensions are essential for creating a necklace that not only looks beautiful but also feels comfortable to wear. In the context of 4 Axis CNC Machining, dimension comparison is used to verify that the machined components meet the design specifications and tolerances.

Measuring and Verifying Dimensions

To ensure accurate dimension comparison, various measuring tools and techniques are used. These include calipers, micrometers, and coordinate measuring machines (CMMs). These tools allow for precise measurement of the dimensions of the machined parts, such as the length, width, and thickness. By comparing the measured dimensions with the design specifications, any deviations can be identified and corrected before the final assembly of the necklace.

Tolerance and Quality Control

Tolerance is an important concept in dimension comparison. Tolerances define the acceptable range of variation in dimensions. In necklace making, tight tolerances are often required to ensure a perfect fit and a high-quality finish. Quality control processes are implemented to monitor and maintain the tolerances throughout the machining process. This includes regular inspection of the machined parts and adjustment of the machining parameters if necessary to ensure that the dimensions remain within the specified tolerances.

Ensuring Consistency in Production

Dimension comparison also helps in ensuring consistency in production. By maintaining strict control over the dimensions of the machined components, manufacturers can produce necklaces that are consistent in quality and appearance. This is particularly important for large-scale production, where consistency is key to meeting customer expectations and maintaining a good reputation in the market.

Conclusion

In conclusion, 4 Axis CNC Machining has opened up new possibilities in the design and production of necklaces. Its precision, versatility, and ability to handle complex designs make it an ideal choice for creating high-quality and unique necklaces. Dimension comparison is an essential part of the process, ensuring that the final product meets the highest standards of quality and fit. As technology continues to advance, we can expect even more innovative and sophisticated applications of 4 Axis CNC Machining in the jewelry industry, further enhancing the beauty and value of necklaces and other jewelry pieces.