Bozhou District: Taking Multiple Measures To Promote The High-quality Development Of Aluminum And Aluminum Processing Industries

On December 25, Bozhou District, Zunyi City held a special press conference on "New Industrialization" to report on the progress of new industrialization in Bozhou District and answer reporters' questions on the progress of aluminum and aluminum processing in Bozhou District.

Basically form a recycling model of "use all minerals, eat them dry, and squeeze them all".> Establish a special class for mineral product remediation to standardize the management of bauxite resources. Classify high, medium and low grade bauxite for use. High-grade [aluminum content of more than 65%] is mainly used for brown corundum, refractory materials, etc., medium-high grade [aluminum content of 45%-65%] is mainly used for alumina, electrolytic aluminum, etc., and low-grade [aluminum content of less than 45%] Mainly used for homogeneous materials, ceramics, etc. Relying on the construction of the national bulk solid waste comprehensive utilization base, the recycling model has formed a pattern of "bauxite - products - waste residue (red mud) - renewable resources". Zunyi Aluminum has become the first electrolytic aluminum company in Guizhou to obtain a green aluminum product evaluation certificate.

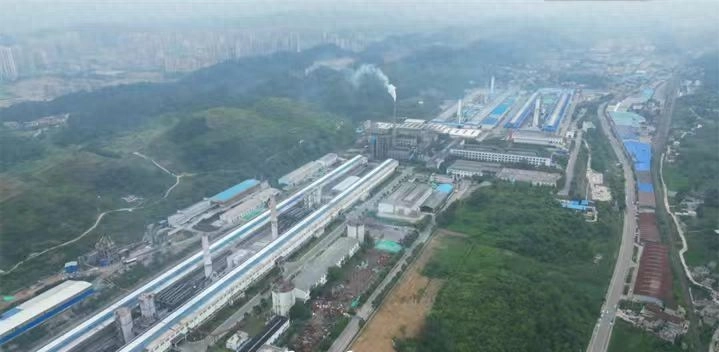

Basically formed a cluster development pattern of the entire aluminum processing industry chain.> A full industrial chain of "bauxite-alumina-electrolytic aluminum-aluminum processing-recycled aluminum-red mud comprehensive utilization" has been formed. The upstream is dominated by leading bauxite mining companies such as Chengqian Mining and Binhui Mining. The main chain enterprises in the midstream are Zunyi Aluminum alumina and electrolytic aluminum, and the downstream mainly include deep processing enterprises such as Zhenghe Aluminum and Hengjia Aluminum, realizing the full-process technology from bauxite to aluminum products. industrial chain.

Technological innovation empowers industrial transformation to accelerate.> Guide enterprises to cooperate with universities and scientific research institutes to focus on the comprehensive utilization technology of low-grade high-sulfur bauxite, build a flotation desulfurization project CNC shop with an annual output of 400,000 tons, and break through the traditional desulfurization technology limit of no more than 3%. Zunyi Aluminum has cooperated with Guizhou Normal University to conduct research on key technologies for dealkalization and soil formation of red mud from Maotai-flavor liquor wastewater. The aluminum industry has 1 national-level specialized and special new "little giant" enterprise, 2 provincial-level "little giants", 8 provincial-level "specialized, special and new" small and medium-sized enterprises, and 9 innovative small and medium-sized enterprises. Medium-sized enterprises.

Guizhou Daily Tianyan reporter Jiang Hongfei>

Editor Wu Haoyu>

Second trial Yangliu>

Tang Zhengping’s third trial>