How Does The School Of Materials Science And Technology Of Central South University Support Industrial Development With Basic Research To Install Independent Copper Alloys For Key Components Of High-speed Rail?

With the world's largest high-speed rail operating mileage and speed, China's high-speed rail strength has been recognized by the international community and has become a bright "China business card."

The development of China's high-speed rail has witnessed the vicissitudes of the nation and the tireless exploration of our country's scientific researchers behind the scenes.

Urban rail transit vehicles rely on traction motors to achieve traction and electric braking functions. But at the beginning of the 21st century, it cost my country more than hundreds of thousands of dollars to import a traction motor. Now, through independent research and development and production, the price of a motor is only several hundred thousand yuan. The key to the significant reduction in production costs lies in the successful development of copper alloy materials for high-speed rail transportation.

The achievement comes from a research team at the School of Materials Science and Engineering at Central South University. As one of the most powerful universities in China in nonferrous metals and metallurgical engineering, Central South University, based on the concept of “going global and telling stories,” has explored a unique path in opening up the “last mile” of industry, academia, and research. Get out there and help. "

"It is not easy for China's manufacturing industry to 'follow' and 'parallel'. If it still wants to 'lead', it is obviously impossible without the accumulation of basic research. Therefore, it must be from two aspects, one is to meet the needs of application The demand for high-performance materials in this scenario requires a large amount of basic research theory accumulation," Professor Zhou Li, Dean of the School of Materials Science and Engineering at Central South University, told New Materials Online®.

Develop high-performance copper alloys to lead motor innovation>

>

The development of copper materials in our country has a history of thousands of years, but in modern times, the copper alloys used in industry have failed to keep up with the times. With the advancement of industry, copper alloys are used more and more widely, and their relevance to the national economy once reached more than 80%. However, due to the scarcity of copper resources, copper processing technology has not been taken seriously, and its application has been restricted abroad.

Just like in the late 1990s, my country's electric motors mainly rely on imports. Technical blockade also prevents domestic copper and copper alloys from finding opportunities for application and verification, resulting in generally low performance and inability to be used in high-power asynchronous traction motors. , seriously restricting the implementation of major projects in our country. Therefore, there is an urgent need to develop economical and practical copper alloy materials with high strength, high conductivity, and heat resistance.

Central South University has a history of more than 70 years in the field of non-ferrous metals and powder metallurgy. In the early days of the founding of the People's Republic of China, the state organized the mining and metallurgy disciplines of six universities including Wuhan University and Sun Yat-sen University into the Central South College of Mining and Metallurgy, and established one of the earliest metal technology departments in the country, conquering the artificial satellites, Long March series rockets, and Shenzhou , high-speed rail, large aircraft and other key material problems required for major national scientific research.

Taking the country's major needs as its own responsibility, the development of copper alloys fell on the shoulders of Zhongnan people.

In 1999, Professors Yin Zhimin and Wang Mingpu of the Department of Materials Science and Engineering of Central South University led a scientific research project: research on key materials for high-power asynchronous traction motor rotors.

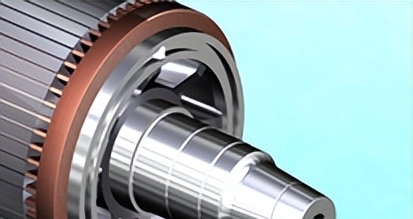

The rotor is usually composed of conductors and magnetic materials, including guide bars, end rings and retaining rings. Since pure copper has excellent electrical conductivity, thermal conductivity, corrosion resistance and good processing properties, it is very suitable for making conductors and end rings of motors with smaller power and lower speed. However, the disadvantages of pure copper are its lower strength and poor resistance to softening at high temperatures.

As an electric motor for rail transit traction power, with the increase of power, rotation speed, vehicle speed and ambient temperature, pure copper can obviously no longer meet the usage requirements.

In order to solve the urgent needs of my country's high-speed rail transportation, combined with Central South University's unique research accumulation of non-ferrous metal materials and comprehensive analysis of application scenarios, Professors Yin Zhimin and Wang Mingpu led the team to propose a solution with high mechanical strength, high conductivity and durability. High-performance copper alloys with high-temperature softening properties are used to manufacture key components of the rotor.

Asynchronous traction motor rotor copper alloy parts

"But it is not easy to develop materials and put them into production lines." Professor Li Zhou sighed when recalling his R&D experience.

At that time, in the material design process, the control of resistivity, heat resistance, and temperature coefficient of resistance were all part of the material design, but because different elements have different functional properties. "The process of material design seems simple, but it actually requires us to go through countless tests in the laboratory to achieve the goal."

In addition, limited by the preparation conditions at the time, the team encountered some difficulties in the process of making the guide rod. Since the school did not have an extrusion machine, the team had to use an extrusion machine from Hongyuan Machinery Factory in Lianyuan, Hunan Province to conduct experiments. Since the machinery factory itself also has production tasks and cost assessment pressures, the scientific research team often has to wait until the manufacturer completes the production tasks at 1 a.m. before conducting experiments. For countless days and nights, teachers and students stayed in the trial production workshop for food and accommodation.

Hard work and unremitting efforts finally brought the joy of success. The team led by Professor Yin Zhimin and Professor Wang Mingpu finally successfully developed a high-performance copper alloy and achieved pilot production at the Copper Alloy Research Institute.

In 2000, when the "Blue Arrow" AC locomotive with a speed of 200 kilometers per hour jointly developed by Zhuzhou Factory and Zhuzhou Institute was completed, the high-performance copper alloy developed by the team was used in it.

The success of the research and application development of copper alloys for high-speed rail transit has also broken the foreign technology monopoly. Our country's motors have also gradually shifted from reliance on imports to independent production.

Since then, high-performance copper alloys have become the key material for high-power asynchronous traction motors, the new power source of my country's rail transit, and have been successfully used in my country's Guangzhou-Shenzhen high-speed railway, subway, Guangzhou, Shanghai, Nanjing, Beijing, Wuhan and other cities. in major projects such as light rail.

"There is a long way to go from the preparation of materials to the final product, and it requires the joint efforts of several generations to achieve it." Professor Li Zhou said with emotion.

Starting from demand, continue to promote research on high-performance copper alloys>

>

"To realize the implementation of results, it is very important to organically combine research topic selection with industrialization. Starting from undergraduates, we encourage students to join scientific research teams, conduct research, and lay basic skills through practical research; many companies help companies overcome technical problems and Take this opportunity to build a systematic understanding of industry needs,” said Professor New Materials Online®.

Just like the case of high-performance copper alloy R&D, Professor Li Zhou concluded that scientific research requires full consideration of the characteristics of the scientific research team, starting from the demand side, closely integrating with actual application scenarios, and overcoming key issues. question.

As the earliest metal materials used by humans, copper and copper alloy processing materials are widely used in many fields due to their high electrical conductivity, high thermal conductivity, corrosion resistance, physical properties and comprehensive properties. However, pure copper has low strength and weak resistance to softening at high temperatures. How to improve copper's strength and develop other functions while maintaining its inherent properties of high electrical conductivity and high thermal conductivity has always been the goal of Professor Zhou Li's team.

Professor Zhou Li's team put forward high-strength, high-elasticity, and high-strength design principles and methods around the design, preparation and processing, phase transformation mechanism, strengthening mechanism, conductive mechanism and stress relaxation mechanism of high-performance copper alloys. -Conductive copper alloy. , and developed high-strength and high-conductivity age-strengthened copper alloys, high-strength and high-conductivity dispersion-strengthened copper alloys, high-resistance stress-relaxation elastic copper alloys, anti-discoloration and corrosion-resistant copper alloys, super-strong copper alloys, high-strength and wear-resistant copper alloys and the above-mentioned high-strength copper alloys. Advanced technology for performance copper alloys. Preparation technology.

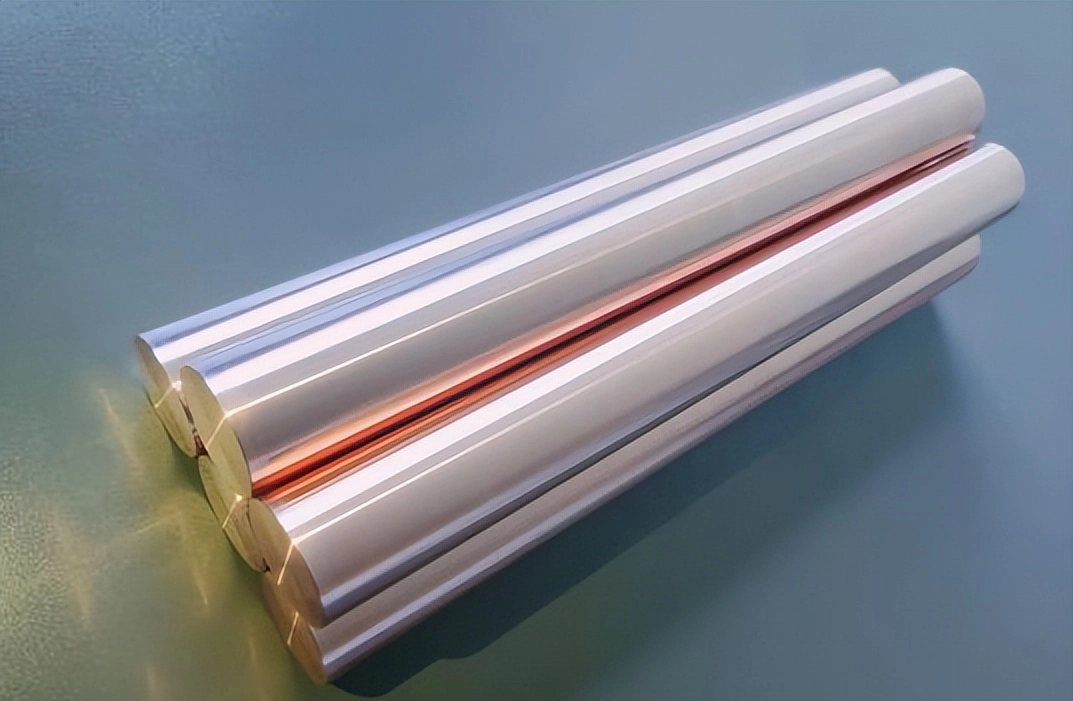

Starting from the high-performance copper alloy team of Central South University, the high-performance copper alloy team of Central South University successfully developed a nano-dispersion strengthened copper alloy. Due to its excellent mechanics, electrical conductivity, thermal conductivity, air tightness and good resistance to high temperature softening, it has been used in the "Shenzhou" series of spacecraft; the developed ultra-high strength conductive elastic copper alloy meets the needs of key materials for navigation systems. The series of high-performance copper alloys and their preparation technologies developed have been implemented in large domestic copper processing enterprises.

High strength, high conductivity, high air tightness dispersion strengthened copper alloy

Composite materials will gradually occupy an important position in the future progress of high-performance copper alloys. "What is unique about composite materials is that they can integrate the properties of different materials into a system to achieve comprehensive and improved performance. This blending process allows the structural and functional properties of the material to be amplified." Professor Zhou Li said .

Talking about the key to the smooth integration of industry, academia and research, Professor Li Zhou believes: "Basic research and discipline construction are the driving force, and the work of industry, academia and research must start from basic research."

At present, China's manufacturing industry needs to move from "following" to "parallel" and then to "leading". Without the accumulation of basic research on a large number of industries or core systems, it is impossible to achieve "leading". To stay ahead, we must focus on two aspects: first, to develop new application scenarios, and second, to make breakthroughs in basic theory.

In the research and development process of high-performance copper alloys, "without primitive accumulation, there would be no continuous development of new copper alloys," Professor Li Zhou said.

Take the IGBT (Insulated Gate Bipolar Transistor) chip, the core component responsible for power conversion in electrified rail transit equipment, as an example. IGBT is called the "CPU" of power electronic devices. It is the core equipment of key components such as the hybrid system and electric drive system of electric vehicles, and directly affects the power output of the vehicle motor.

Since the opening of high-speed rail trains in 2004, my country's high-speed rail trains have needed to import about 100,000 IGBT modules every year, worth more than 1.2 billion yuan.

Currently, ceramic copper-clad laminates used in chip manufacturing mainly rely on imports because of challenges such as welding processes during the manufacturing process. High-voltage IGBT modules generally adopt standard welding packages. In principle, when welding in a high-temperature environment, it is required that the grains of DBC ceramic copper-clad laminates cannot grow up after welding, otherwise the welding quality will be affected.

"But how to design copper alloys or pure copper materials so that the grains will not grow too large at high temperatures involves a lot of basic research," including grain boundary structure control, trace element grain boundary segregation behavior and its impact on grain boundaries. Influence. "So basic research is very important. Without the guidance and support of basic theory, it will be difficult to produce breakthroughs and innovations." Professor Zhou Li said.

In addition, the transformation of scientific research results as the "last mile" of industry, academia and research is also crucial.

Central South University has always been committed to promoting the implementation of scientific research results. The School of Materials Science and Technology actively implements the relevant requirements and arrangements of the school and adheres to the principle of "go out, speak out, and help." In the past five years, the results have been successfully converted into contract funds reaching 300 million yuan.

Professor Li Zhou introduced that the so-called "going out" means actively connecting with various enterprises, exchanging the research characteristics, directions and research results of the faculty of the college, so that enterprises can understand the technical achievements, technical reserves and research directions of the college and establish a good cooperative relationship with the college. . “Speaking out” requires teachers to actively participate in academic and industry conferences. Through the sharing of scientific research results and technology, more people can understand and understand the scientific research strength and scientific research results of the college. "Help" refers to proactively providing help when solving problems encountered by the company, integrating the team's technology into the company through technology transfer, cooperative development, etc., to achieve the effective transformation of scientific research results. "Through these measures, we not only solved the company's problems, but also transformed the results into new products, achieving a win-win situation." Professor Li Zhou said.