Manufacturing Process Of Precision Machining Factory (precision Machining Machine)

With the continuous development of modern manufacturing industry, the precision machining industry is also facing new opportunities and challenges. In this highly competitive market, manufacturing technology is a crucial part. Only through scientific manufacturing technology can we ensure product accuracy and quality cnc machining shop, improve production efficiency and product quality, and enhance the competitiveness and market share of enterprises. The manufacturing process of precision machining factories will be introduced from many aspects and corresponding suggestions will be made.

1. Processing process planning

Processing process planning is one of the important directions in the manufacturing process of precision machining factories. Since processing technology is directly related to product quality and production efficiency, companies can optimize processing technology through processing technology planning, improve production efficiency and product quality, and reduce production costs and the impact of human factors on products. For example, a precision machining factory has achieved standardization and automation of the processing process through planning and optimization of processing processes, improved production efficiency and product quality, and reduced production costs and the impact of human factors on products.

2. Selection and use of tools

The selection and use of cutting tools is also one of the important directions in the manufacturing process of precision machining factories. Since the selection and use of cutting tools are directly related to product quality and production efficiency, through the selection and use of cutting tools, companies can improve product accuracy and surface quality, improve production efficiency and product quality, and reduce production costs and human factors on products. influence. tool. Influence. For example, a precision machining factory has implemented standardized management of the selection and use of cutting tools of different materials to extend tool life and reduce wear, improve product accuracy and surface quality, and reduce production costs and the impact of human factors on products. product. .

3. Processing parameter control

Processing parameter control is also one of the important directions in the manufacturing process of precision machining factories. Since processing parameters are directly related to product quality and production efficiency, companies can optimize processing technology through processing parameter control, improve product accuracy and surface quality, improve production efficiency and product quality, and reduce production costs and the impact of human factors on products. . For example, by controlling and adjusting processing parameters, precision machining factories achieve stability and consistency in the processing process, improve product accuracy and surface quality, improve production efficiency and product quality, and reduce production costs and labor costs. Factors affecting the product.

4. Quality management

Quality management is also one of the important directions in the manufacturing process of precision machining factories. Since quality management is directly related to product quality and customer satisfaction, companies can ensure product quality is stable and meet standard requirements through quality management, improve customer satisfaction and trust, and enhance the company's competitiveness and market share. For example, a precision machinery processing factory has established a complete quality management system and quality inspection system through comprehensive and standardized quality management management, effectively ensuring the quality of its products.

-------------------------------------------------- -----------------------

[Precision parts processing] Please click to enter

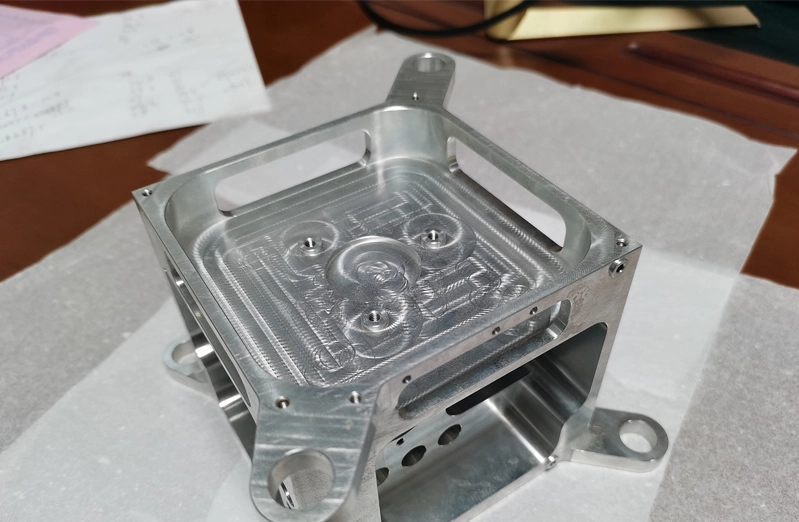

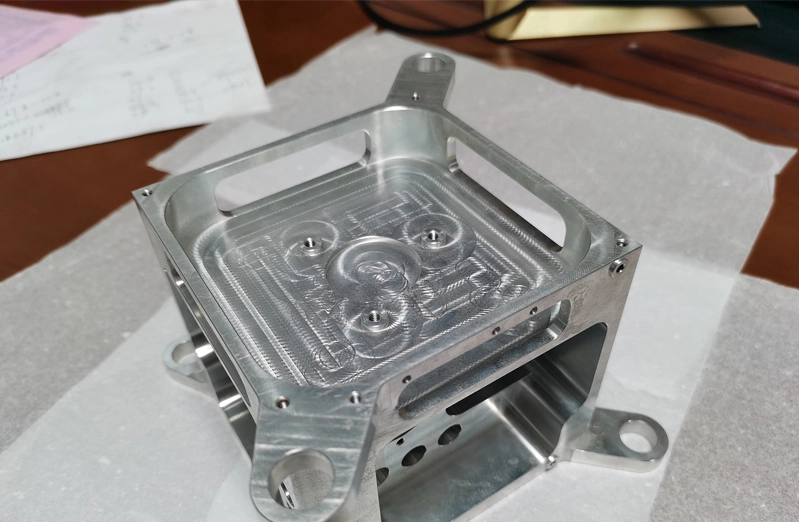

The above content was shared by the senior processing technician of Shenzhen Jieberui Technology Co., Ltd. JB Precision Manufacturer is a machining manufacturer specializing in precision parts processing, non-standard parts processing, high-end product casing processing, starting from customized design to handle implementation. Since its establishment in 2013, the company has processed more than 12,000 boxes of various high-end casings and high-precision parts. The professional engineering and technical team provides customers with high-quality services. Friends from all walks of life are welcome to visit our company for guidance and business negotiation! (Article from) Welcome to consult!