MasterCAM Impeller Processing Explanation

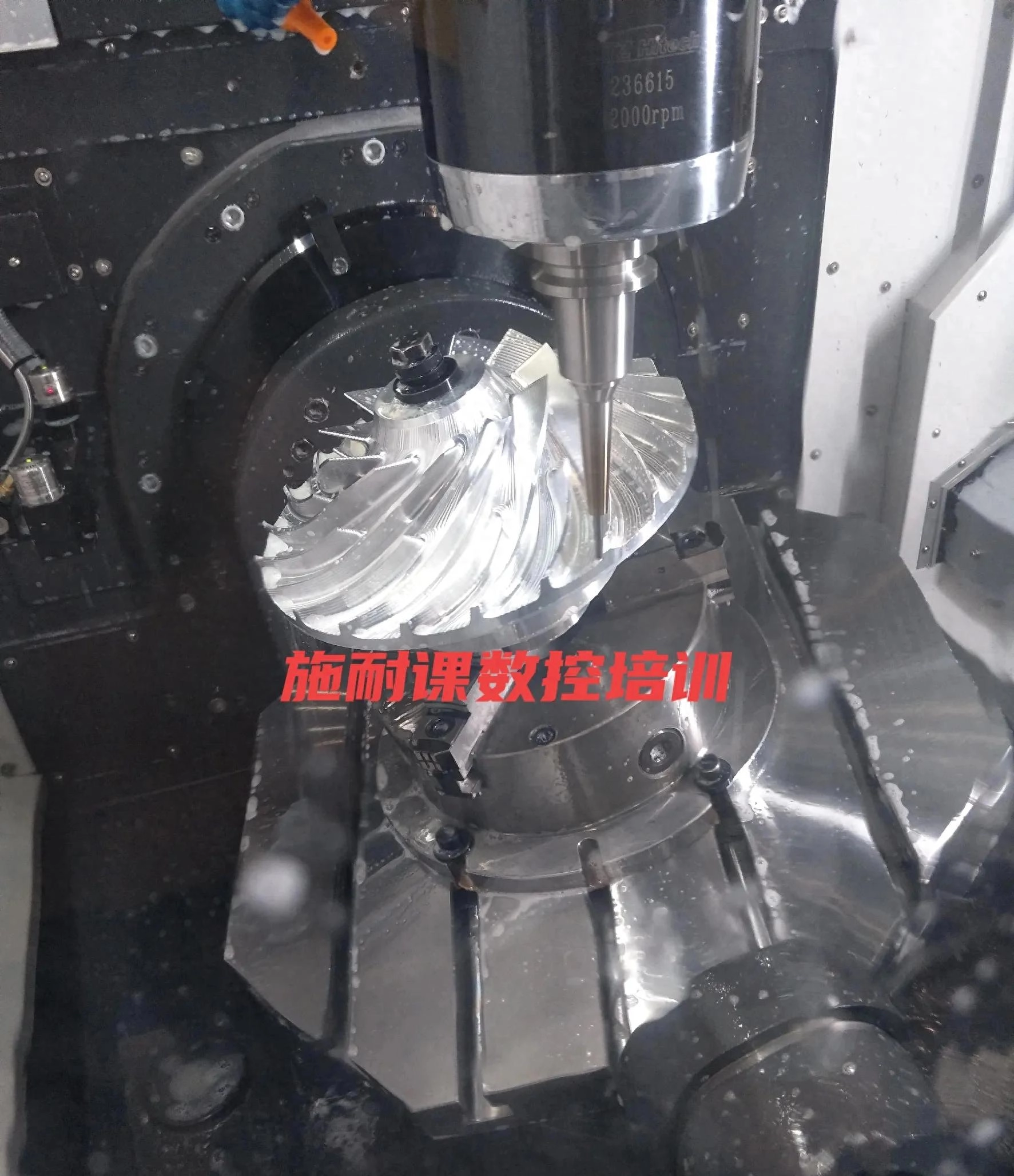

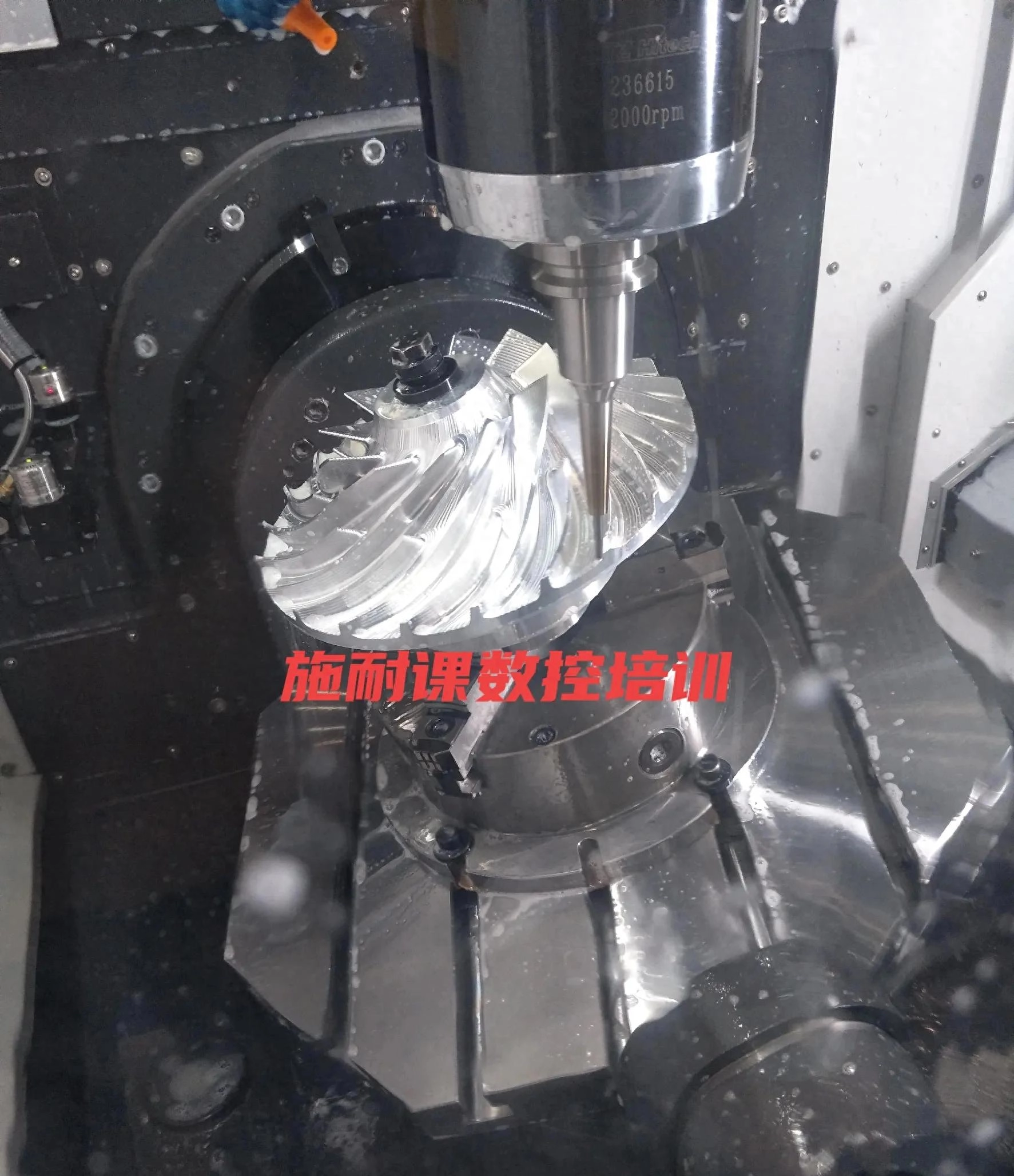

The five-axis impeller is a key component of power transmission machinery and is widely used in aerospace and other high-precision equipment fields. In order to obtain the best transmission power advantage and endurance in a long-term high-speed rotation environment, precision machining of five-axis impellers is an important issue in high-end manufacturing. The programming method and importance of five-axis simultaneous machining of impellers are very important for machining. The tooling aspect is very critical.

Five-axis machining of thin-walled parts of impeller blades requires poor rigidity, weak willfulness, high anisotropic surface quality requirements, large fluctuations in tool axis and vector, and very strict requirements on the entire contour size. Resistance and deformation are prone to occur during processing. Tolerances on parts become larger, affecting overall quality.

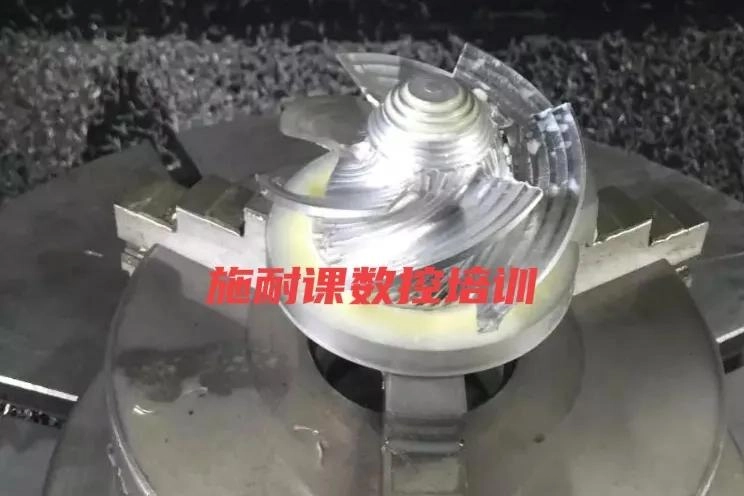

The software programming of the linkage impeller and the intelligent manufacturing of thin plate processing involve unique power machining technology in five-axis machining. It effectively avoids tool cutting time during processing, reduces resistance and eccentricity, improves material deformation during processing, effectively improves heat accumulation during processing, and avoids the occurrence of thermal deformation of materials.

Smoothing filter settings are required in intelligent machining to ensure machining accuracy and maximize the smoothness and durability of tool paths during machining.

Nodes in programming and manufacturing improve the machining process, improve the tool axis vector translation change, improve the surface quality, and meet the contour size requirements.

In this intelligent manufacturing and processing of the five-axis linkage impeller, MC's solution optimization case was demonstrated based on the problems of the five-axis linkage impeller on site. Perfect use of CAM software for programming optimization brings optimization and improvement of five-axis linkage processing efficiency and processing effects. .

Schnik CNC training shows you the following more five-axis CNC intelligent manufacturing and processing products. The processing methods of different special-shaped products are basically the same, but the programming sequence and process are different. Different machine tools and structures have nothing to do with programming. The key is to just deal with the paired machine tools later!