VERICUT Simulates The German Zimmermann Six-axis Five-linkage Gantry Milling Machine Solution

The German company Zimmermann has been committed to the milling of special profiles. Since its founding in 1938, the company's business has mainly involved the cutting and correction of external profiles in different materials. It has become the world's leading manufacturer of high-tech gantry milling machines. Zimmermann's gantry machining centers have extensive experience in many fields such as the automotive industry and the aviation industry. Base. The company successfully achieved 6-axis machining using an FZ100 gantry milling machine and an M3 ABC 3-axis milling head. In the fields of large cutting volume processing such as aluminum alloys, composite materials, model materials, HSC high-speed cutting steel, and cast iron, this processing concept solves the bottleneck processing of traditional 2-axis fork milling heads and 5-axis linkage milling heads. The weak points of traditional 2-axis milling heads - extreme point problems or limited swing ranges - have been solved by the newly developed 3-axis milling heads. The newly added arc guide rail perfectly combines all the existing advantageous concepts and adds a new dimension to the 5-axis linkage machining method.

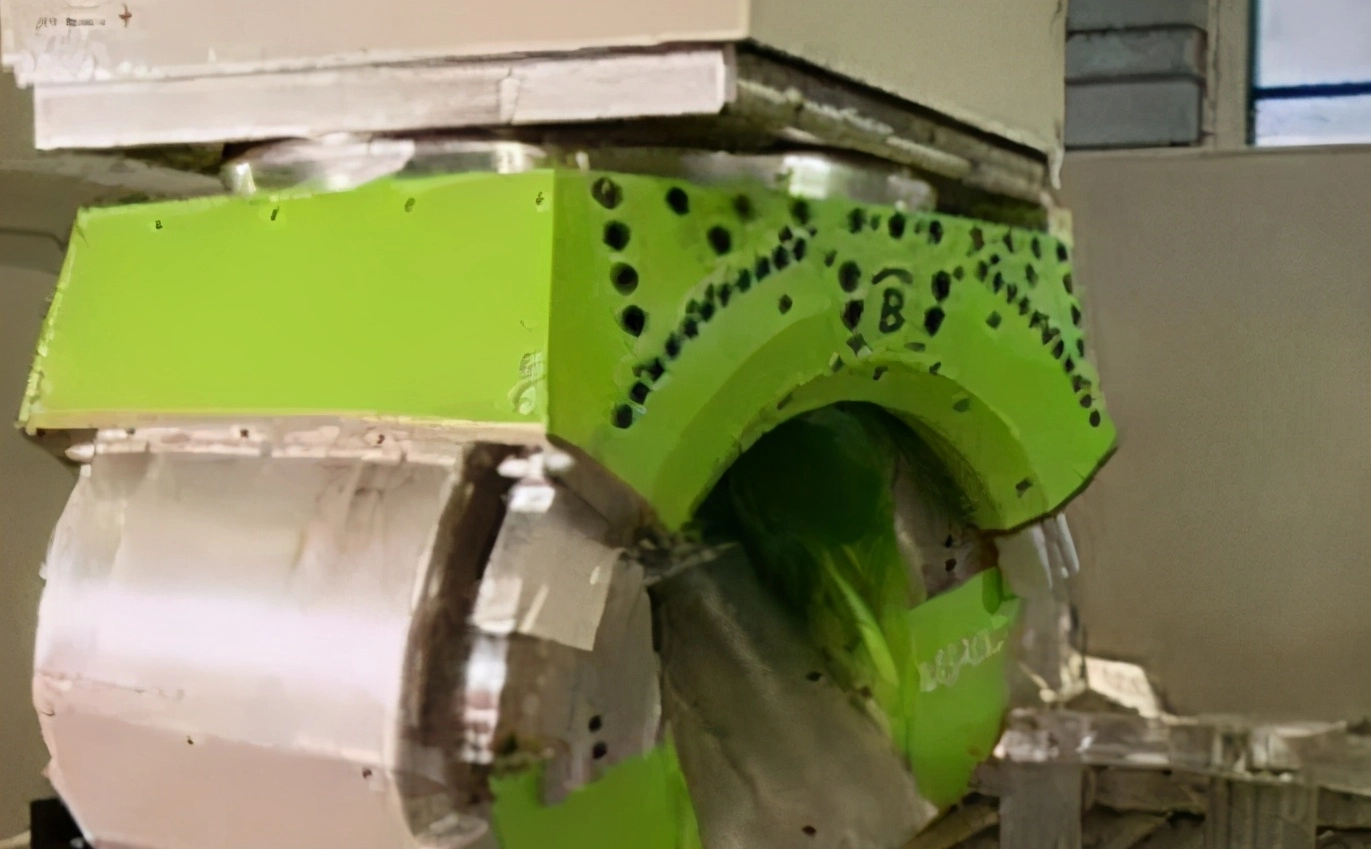

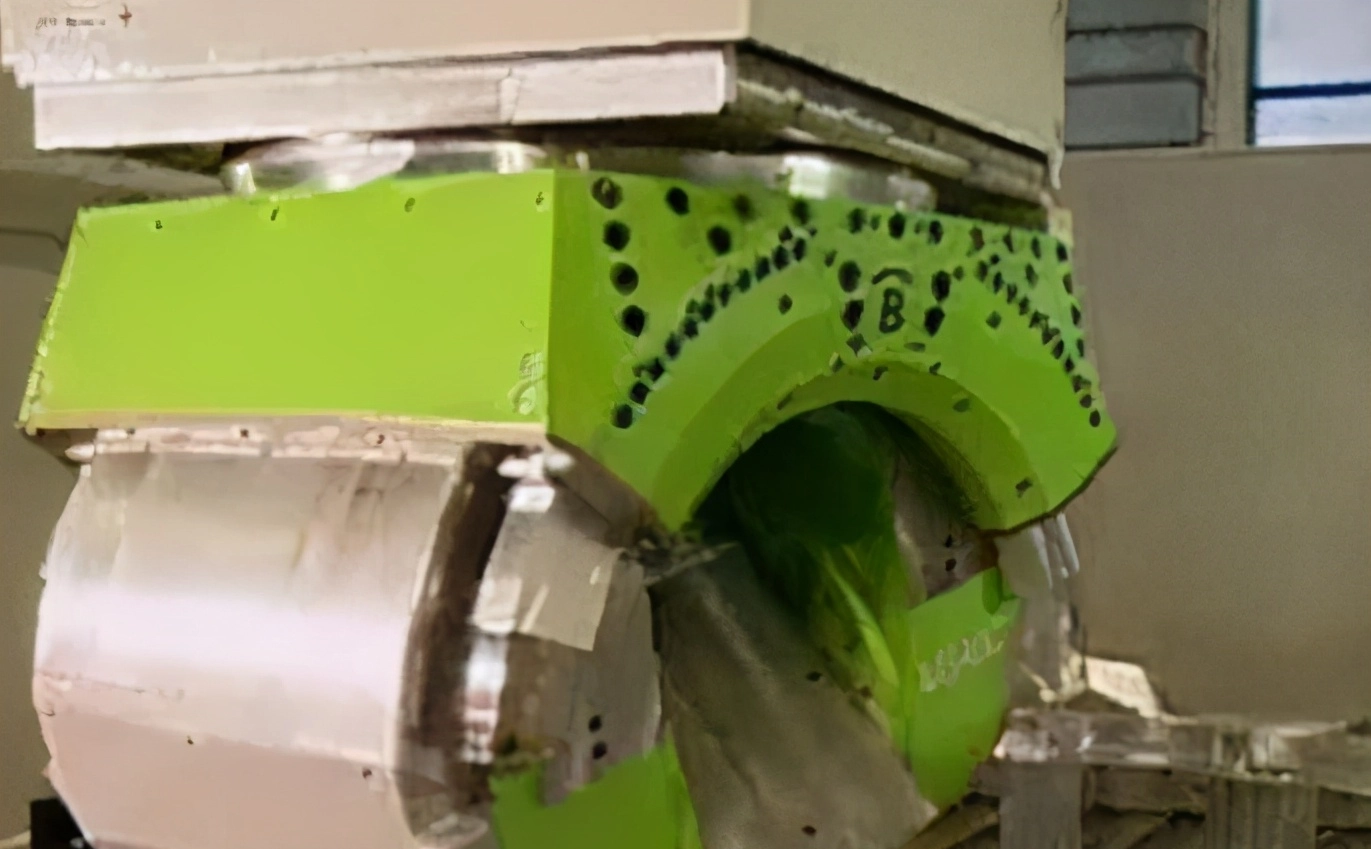

Machine tool photos (source network):

When it reaches 0°, the C axis is parallel to the milling spindle, which is called a polarity problem. The result is that the C-axis is completely unable to rotate the spindle at this time. All movements of the spindle must be completed through the A-axis, and the C-axis can only be used to pre-adjust the A-axis. Therefore, even the smallest spindle movement (such as a few arc seconds of rotation) can cause the C-axis to rotate up to 90°. This results in excessive machine tool idle travel, a serious drop in processing efficiency, and the problem of cross-quadrant overtravel.

This challenge is particularly obvious in five-axis simultaneous machining. With the extreme rotation of the C-axis, the vertical spindle looks like "dancing" on the workpiece surface, which has a negative impact on production efficiency, surface processing quality and tool life. All have negative effects. There is another limitation. Recent developments in machine tool compensation and improved spatial accuracy cannot be applied to 2-axis milling heads, so there is a need to use milling heads without polarity issues.

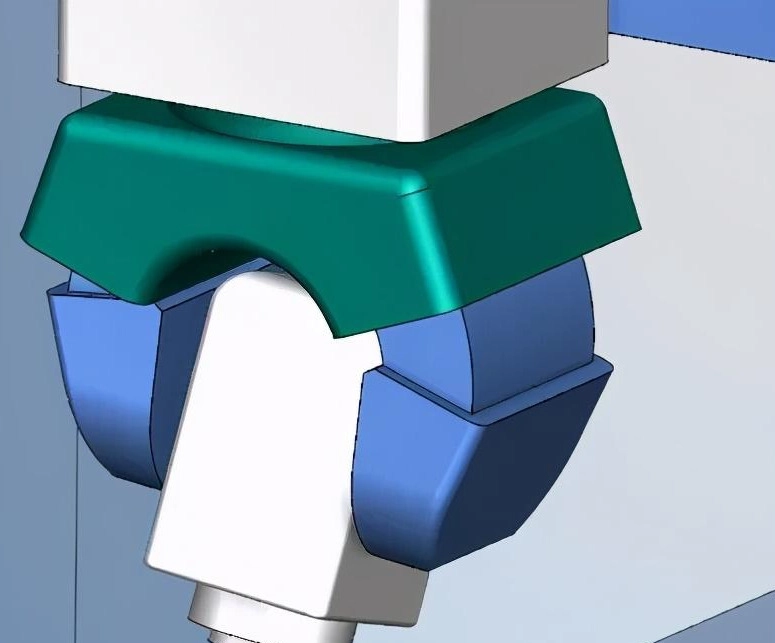

Machine tool photos (source network):

Such milling heads without polarity problems are already in use, for example in the aircraft manufacturing industry, but these milling heads have limitations due to their small rotation range and large size. The solution was the new and unique M3 ABC milling head, the first so far to combine all the advantages of other milling heads.

M3ABC shape. In the picture you can see that the milling head has improved the spindle head of the swing fork. Adding a B-axis between the A-axis and the C-axis allows the swing fork to rotate ±15° along the B-axis arc guide rail. Although the rotation angle is not large and the speed is not high, it is enough to eliminate the problem of the spindle rotation dead center when milling angles, and can realize 5-sided processing, creating a new situation for ABC axis milling heads.

The new three-axis milling head M3 ABC integrates multiple applications: the large swing angle is enough to cope with various processing requirements and completely solve the ultimate problem. With curved rail technology, existing advantageous concepts can be combined for the first time.

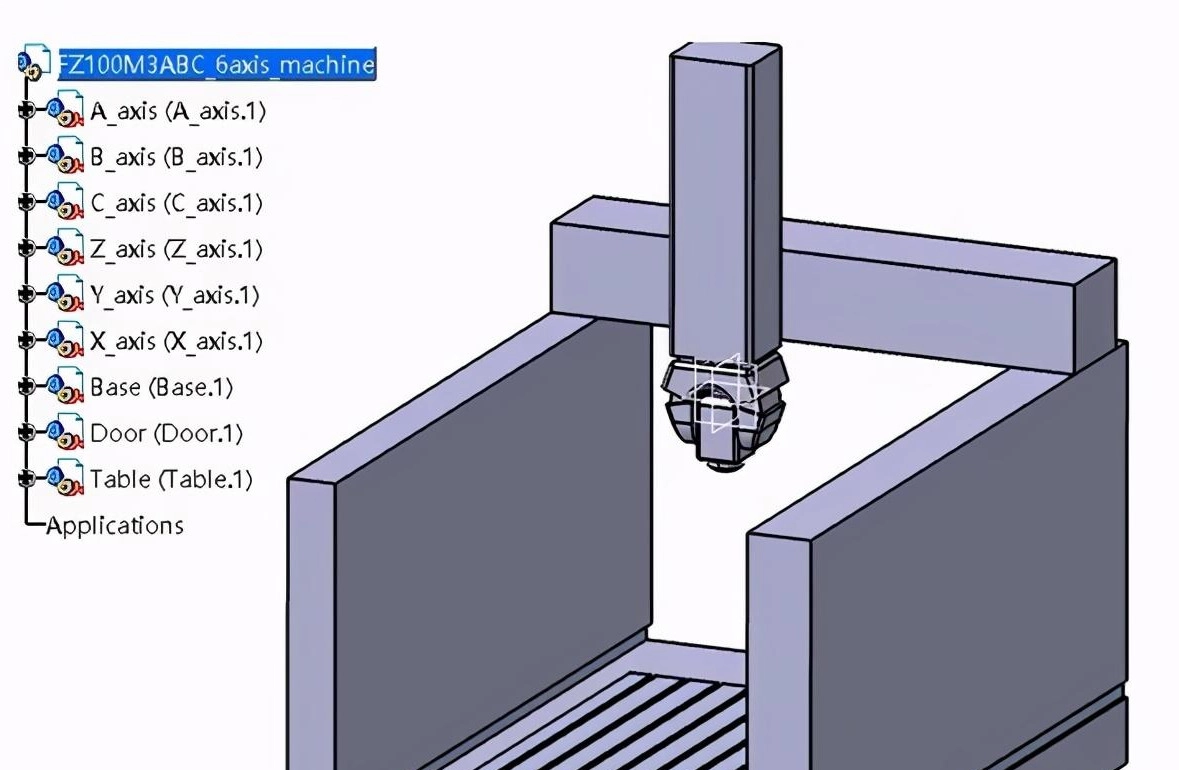

Create a digital model:

However, it is worth noting that although this machine tool has three swing angles A, B, and C, it can only achieve simultaneous linkage of two swing angles. The third swing angle can only be treated as a fixed swing angle of the attitude axis. It is actually a six-axis five-linkage machine tool. Of course, at present, almost all similar machine tools can only achieve five-axis linkage, which is equivalent to combining functional machine tools with AB-axis and AC-axis linkage. However, even so, the difficulty of related programming, simulation, and post-processing work has doubled. Therefore, it is difficult to see such CNC machine tools in reality.

Establish the kinematic relationship of the VERICUT machine tool:

Digital Analog Import VERICUT:

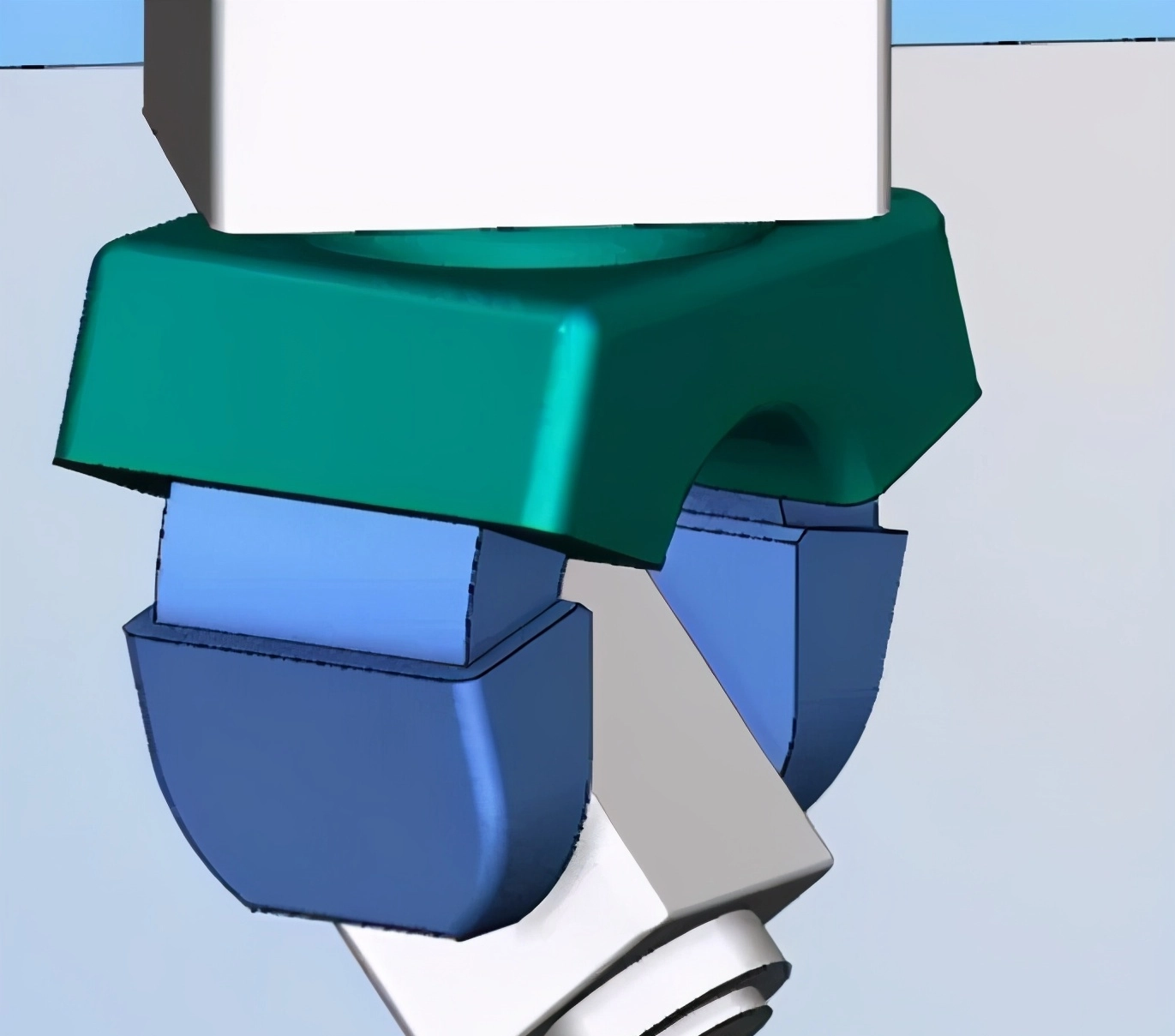

Action decomposition simulation ZYZ+CA:

Traditional high-angle milling

Action decomposition simulation ZYZ+BA:

Suitable for milling ribs, open contours with angles less than 15 degrees, and continuous machining of closed contours without retracting. That's the beauty of this machine.

Linked action simulation:

Any two of the CBA axes are linked to the XYZ axis, and the remaining one is the attitude adjustment axis.