UV Femtosecond Laser Cutting And UV Picsecond Laser Cutting: Who Is The King Who Is Precisely Processed?

In modern manufacturing, laser cutting technology has become the core tool for high-precision processing. In particular, UV lasers and UV lasers have become "star players" in the field of precise processing, with ultra-short pulses and high energy density. But, what is the difference between the two technologies? Who is more suitable for your processing needs? Today, let's find out the answer!

1. Pulse Width: Time Comparison>

The core of laser cutting is "fast", and the gap between femtoseconds and is the gap in time.

Femtosecond laser: 1 second = 10⁻ seconds, the pulse width is very short, and the energy is immediately released with almost no heat influence.

- ** laser **: 1 =10⁻² seconds. Although it is also very fast, it is still 1000 times slower than femtosecond and has a slightly larger thermal impact.

Femtosecond laser is better in time and is suitable for extremely high thermal impact requirements

2. Heated zone: Who is more "cold"?>

The heated zone is an important indicator for measuring the quality of laser cutting. The smaller the heat influence, the smaller the material damage, and the higher the processing accuracy.

Femtosecond laser: The thermal impact zone is very small and almost negligible, especially suitable for heat-sensitive materials (such as semiconductors, biomaterials).

Personal computer. Second laser: The thermally affected zone is relatively large, but it is still far beyond traditional lasers and is suitable for most traditional materials.

Femtosecond lasers perform better in terms of “cold treatment”, but picosecond lasers can also meet most needs.

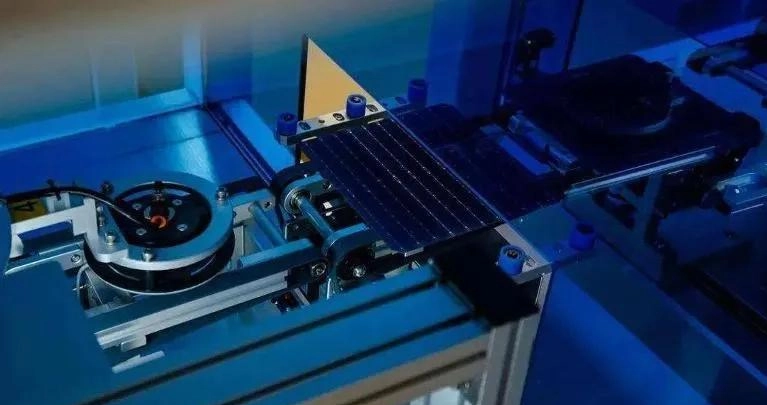

3. Processing accuracy: micro-level showdown>

In the field of precision processing, precision is life.

Femtosecond laser: Due to its extremely short pulses and concentrated energy, it can achieve ultra-high precision processing, even reach submicron levels.

Personal computer. Second laser: Accuracy is slightly lower than femtosecond, but can still achieve microscopic processing to meet most high-precision needs.

Conclusion: Femtosecond lasers are more suitable for extremely precise processing solutions, while picosecond lasers are a cost-effective choice.

4. Applicability of materials: Who can "do your best"?>

Different materials also have different requirements for lasers.

Femtosecond laser: suitable for handling heat-sensitive, high hardness and high brittle materials such as glass, ceramics, semiconductors, etc.

Personal computer. Second laser: It has a wider application and can handle everything from metal to non-metallic materials, but is slightly inadequate in thermally sensitive materials.

Conclusion: Femtosecond lasers have greater advantages in handling special materials, while Laser is a "all-round player".

5. Cost and Efficiency: Who is more cost-effective?>

Technology and costs are usually unavailable at the same time.

- Femtosecond laser: The equipment is complex, the technical threshold is high, the cost is expensive, and the processing speed is slow.

- Photography Second Laser: The device is relatively simple, low-cost, and faster processing speed.

**Conclusion**: If the budget is sufficient and the final accuracy is pursued, femtosecond laser is the best choice; if the cost-effectiveness and efficiency are pursued, picosecond laser is more suitable.

6. Application Solution: Who is more suitable for you?>

- Femtosecond laser: suitable for high-end manufacturing fields, such as medical equipment, cnc machining factories, semiconductors, optical components, etc.

- Laser: Suitable for conventional high-precision processing sites, such as consumer electronics, automobile manufacturing, precision machinery, etc.

Abstract: Femtosecond vs. How to choose?>

- Choose Femtosecond: If you need extremely high accuracy, minimal thermal impact and adequate budget.

- Choice: If you pursue high-cost performance and efficiency, and deal with requirements relatively regularity.

Whether it is femtosecond or picosecond, they are driving advances in precision machining technology. Which technology you choose depends on your specific needs and budget. I hope this article helps you find the most suitable laser cutting solution!