shock! This Taiwan MS Series Milling Cutter Makes 304/316 Stainless Steel Processing As Easy As Cutting Tofu

In the field of metal processing, 304/316 stainless steel is widely used in all industries to show excellent corrosion resistance and high strength. However, when dealing with these two stainless steel materials, the choice of tools often gives practitioners a headache. When ordinary milling cutters face the toughness of 304/316 stainless steel, they often fail to achieve metal cnc machining, resulting in severe wear and low machining efficiency. But now, Taiwan's MS series special stainless steel cutting machines have appeared, which has completely changed this situation!

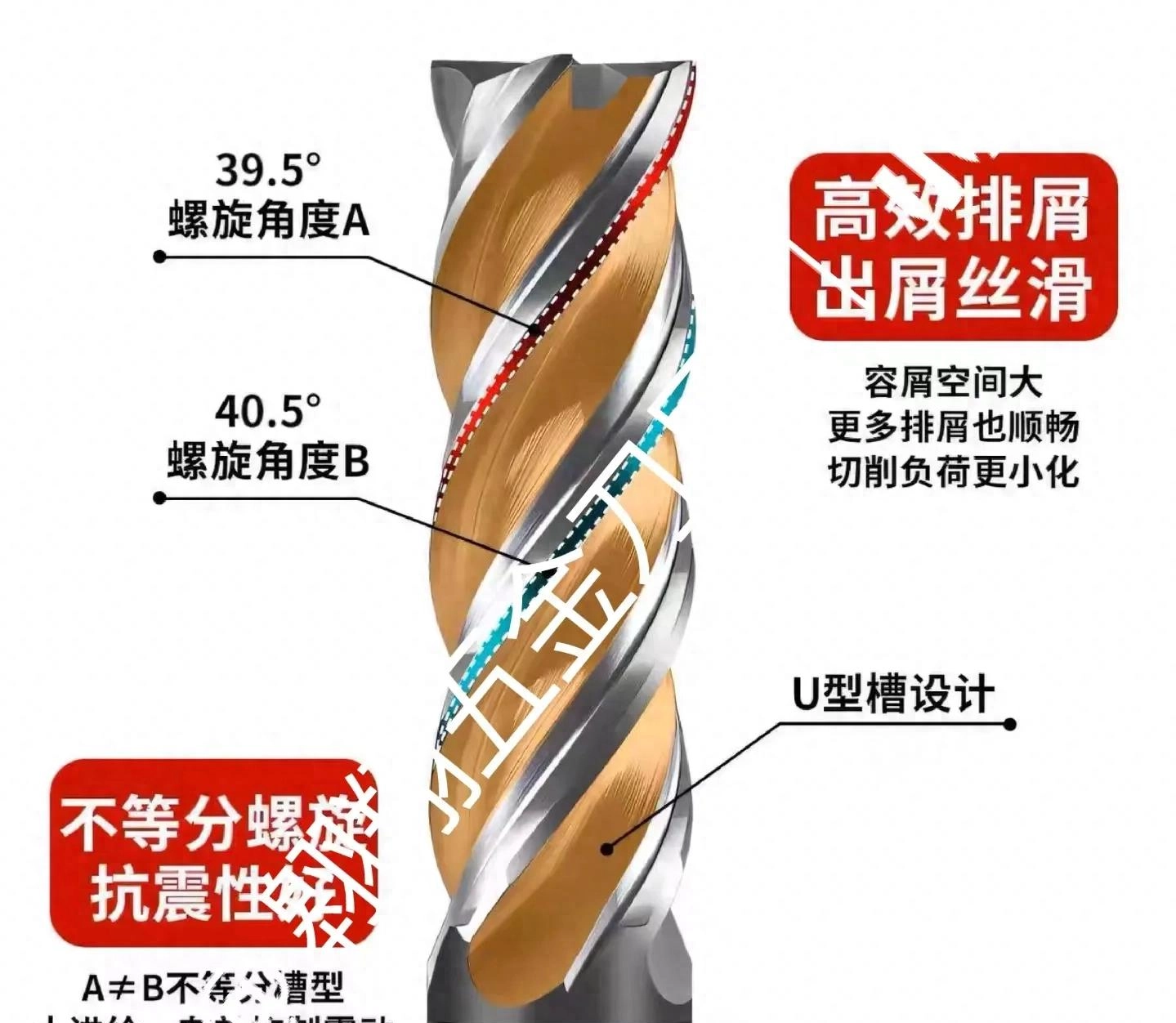

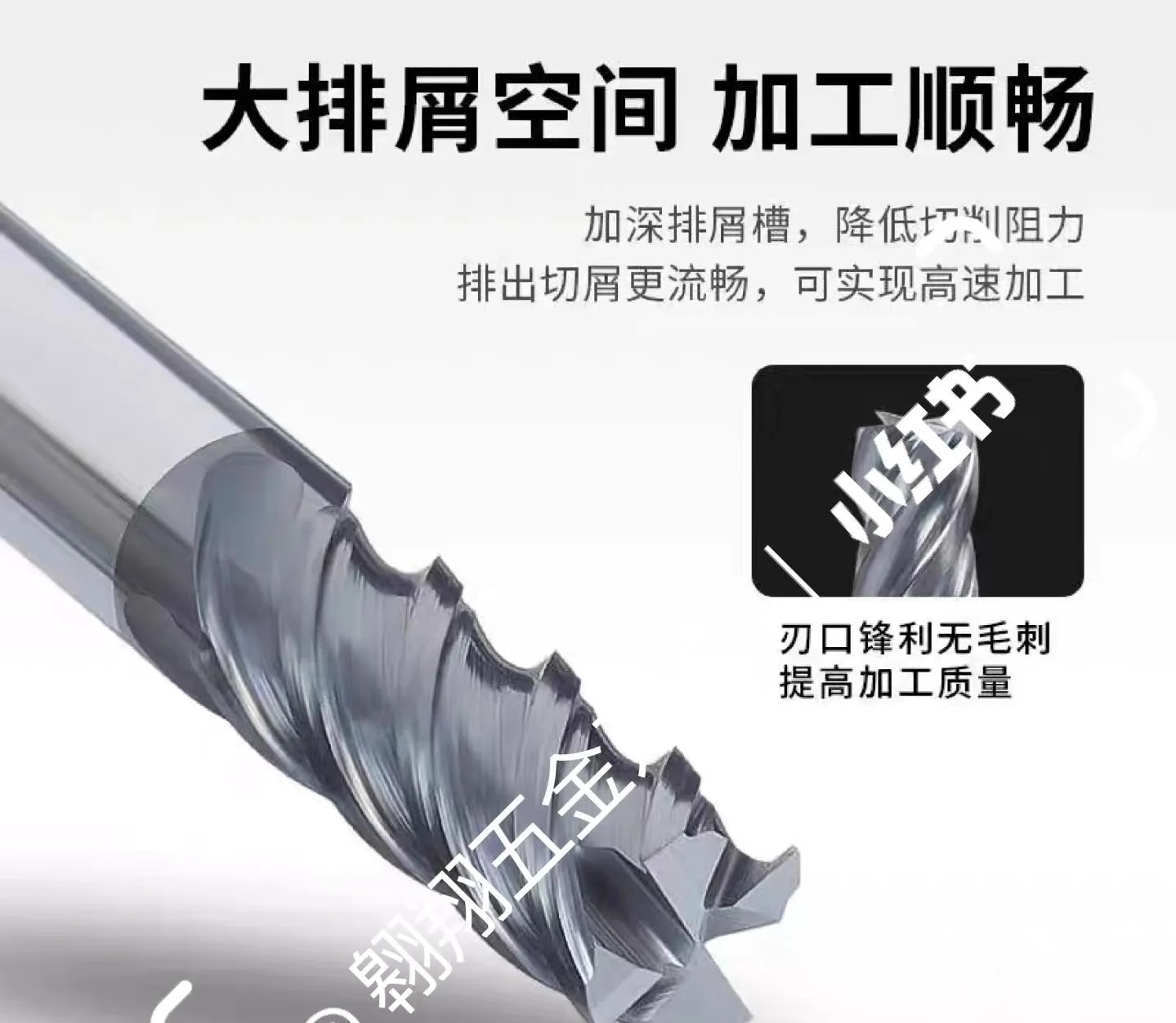

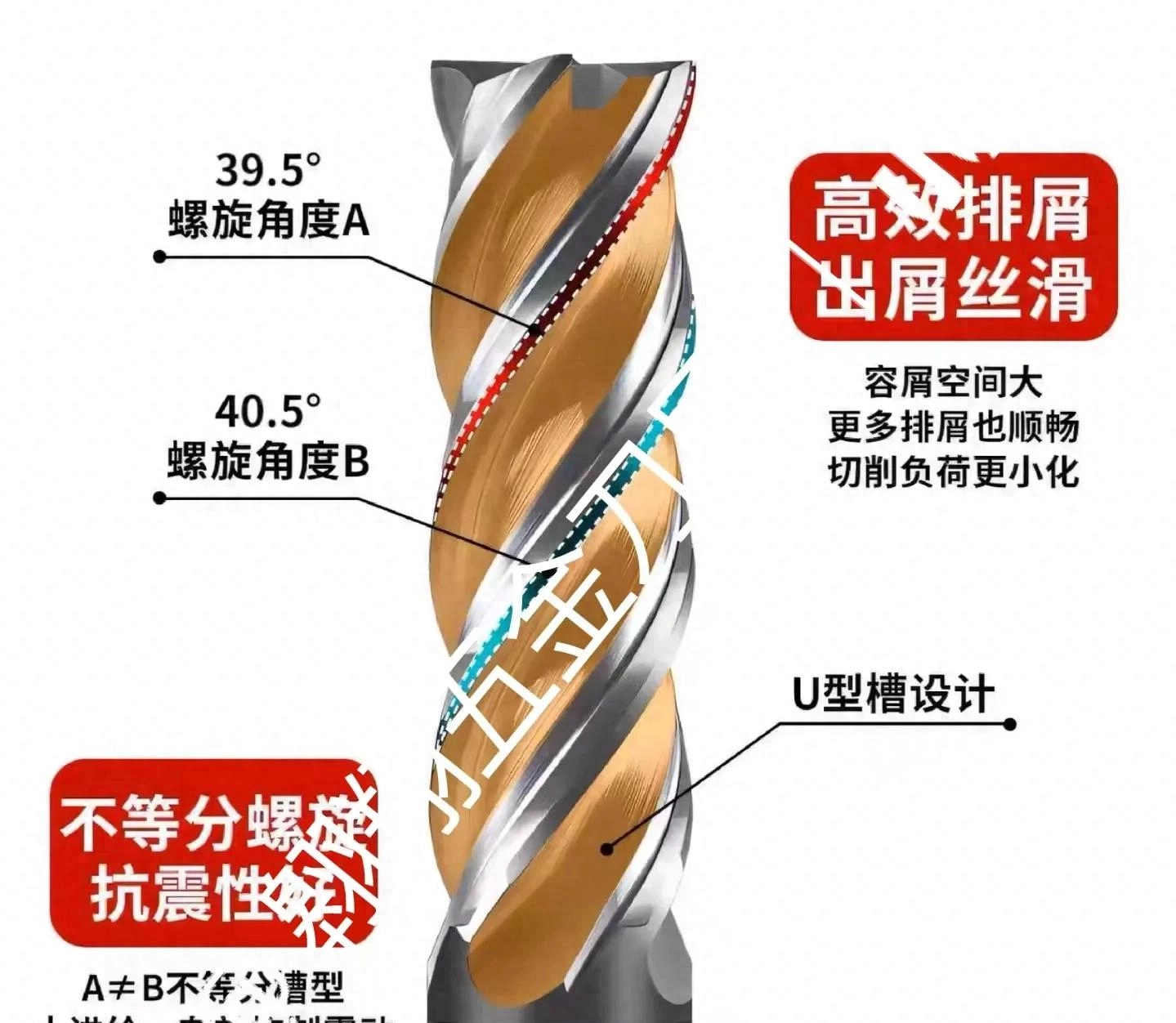

This MS series milling cutter is specially customized for 304/316 stainless steel processing. It adopts a four-sided design, and its unique edge shape has been carefully optimized to greatly improve cutting efficiency during the cutting process. Compared with traditional milling cutters, the four-side design makes the tool and workpiece contact area larger and the cutting force distribution is more even, so more materials can be removed per unit time and the processing efficiency is greatly improved. Imagine the stainless steel machining task that took several hours to complete, but now it can be processed with the help of this milling cutter in just a few dozen minutes. Will bring great benefits to your production!

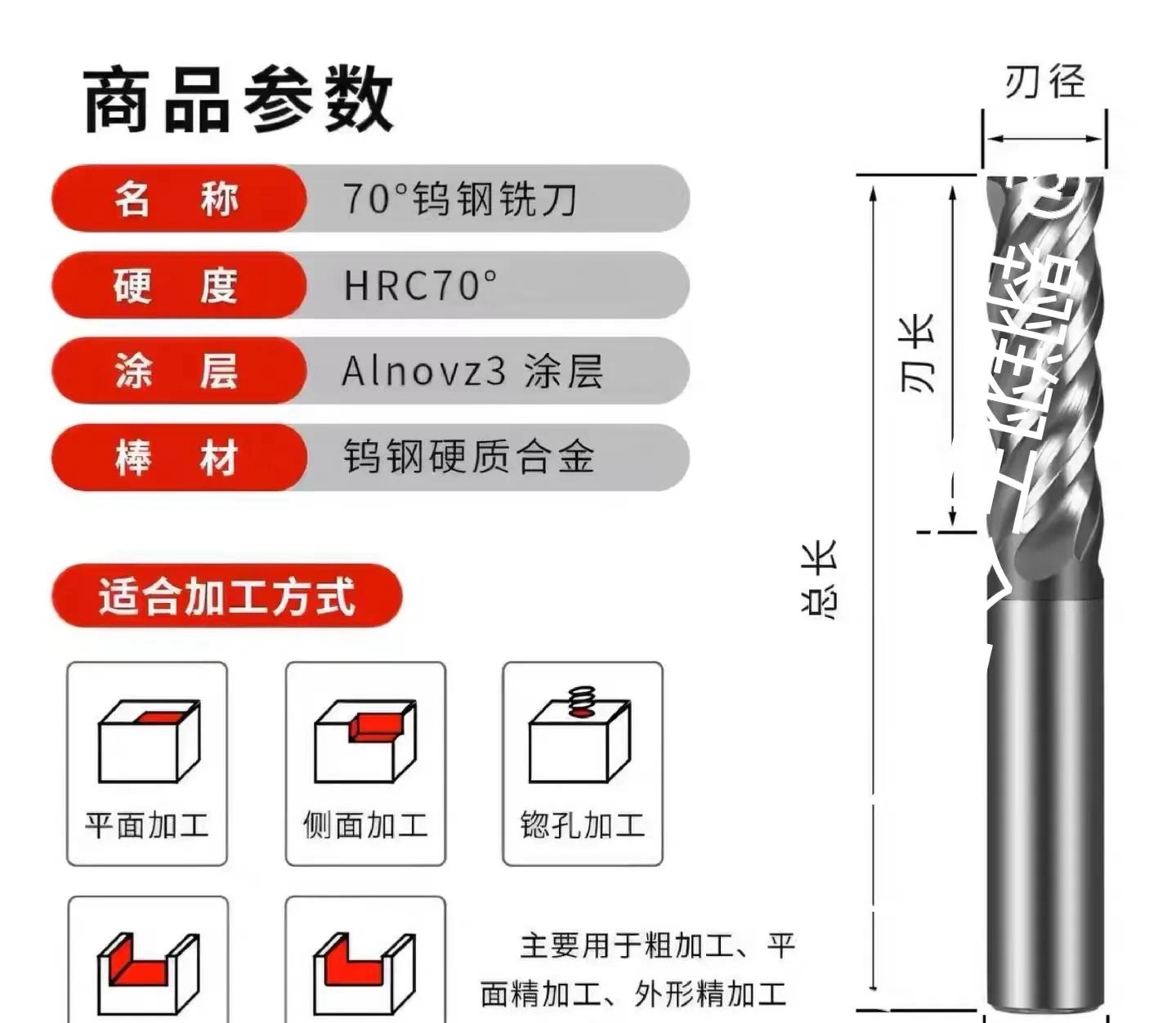

Not only that, the MS series milling cutters are also made of high-quality tungsten steel. Tungsten steel has extremely high hardness and wear resistance, and the milling cutters can maintain sharp edges when facing hard bones (such as 304/316 stainless steel). Even if the tool is continuously processed for a long time, the tool wears very slowly and can extend the life of the tool. No more tools need to be replaced, which not only saves tool costs, but also reduces downtime due to tool replacement, allowing your production line to run continuously and efficiently.

During the actual processing, the surface quality of the 304/316 stainless steel workpieces treated with MS series milling cutters was surprising. It has extremely high processing accuracy and low surface roughness, which can almost achieve mirror effect. This means you no longer need to do additional post-processing processes such as grinding, further savings on processing costs and time. Whether it’s making precision medical equipment parts or high-end stainless steel ornaments, this milling tool is extremely capable and creates impeccable products for you.

If you are still worried about the processing of 304/316 stainless steel, then Taiwan MS series stainless steel special milling cutters are definitely your savior. It opens new chapters in stainless steel machining, with excellent performance, efficient machining features and excellent durability. Don’t hesitate now, choose MS series milling cutters to take your machining business to a new level!