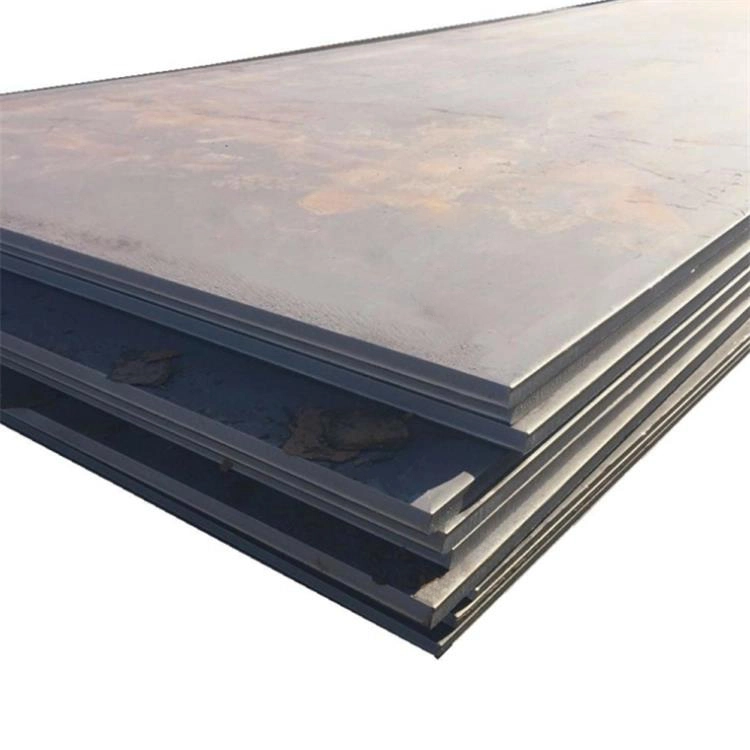

Cold rolled sheet-SPCC material

Basic introduction:

Cold rolled sheet (English name: cold rolled sheet) refers to the process of continuously rolling steel ingots into coils or sheets of required thickness through a cold rolling mill. The surface of SPCC is not maintained and is easily oxidized when exposed to air, especially in a humid environment. It has dark red rust and should be painted, electroplated or other protective measures should be taken during use. Steel sheets with high silicon content have low brittleness and plasticity and need to be preheated to 200°C before cold rolling. Since cold rolled sheets are not heated during the production process, there are no defects such as pitting and iron oxide scale that often occur in hot rolling, and the surface quality is good and the finish is high.

At the same time, the cold-rolled products have high dimensional accuracy, and the performance and organization of the products can meet some special use requirements, such as deep drawing performance, electromagnetic performance, etc. Cold-rolled coils are widely used, such as automobile manufacturing, electrical products, locomotives, aviation, precision instruments and food cans.

Chinese name | Cold rolled sheet | Foreign name | cold rolled sheet |

category | alloy steel | Brand | SPCC |

Technology | Rolling at recrystallization temperature | use | Automobile manufacturing, electrical appliances, etc. |

SPCC brand description:

SPCC in CNC fabrication was originally the name of the steel product "general purpose cold-rolled carbon steel sheet and strip" in the Japanese standard (JIS). Many countries or companies directly use it to indicate similar steel products they produce (for example, Baosteel's Q/BQB402 standard has SPCC).

Common structural steel in Japanese steel (JIS series) grades mainly consists of four parts:

Part I | Indicates material | S (Steel) stands for steel, F (Ferrum) stands for iron |

Part 2 | Indicates different shapes, types, and uses | P (Plate) stands for plate, T (Tube) stands for tube, and K (Kogu) stands for tool |

Part 3 | Indicates a characteristic number, usually the minimum tensile strength | For example: SS400 - the first S stands for steel, the second S stands for structure, 400 is the lower limit of tensile strength 400MPa, and the whole represents ordinary structural steel with a tensile strength of 400MPa. |

Part 4 | Indicates level | For example: C-common, D-drawing, E-Elongation |

Supplement: SPCC--represents general cold-rolled carbon steel sheets and strips, whose chemical composition and mechanical properties are equivalent to Chinese grades Q195 and Q215A. The third letter C is the abbreviation of Cold.

Current plate thickness:

Plate Thickness | Maximum processable size |

0.5 | 2440*1220 |

0.8 | 2440*1220 |

1.0 | 2440*1220 |

1.2 | 2440*1220 |

1.5 | 2440*1220 |

2.0 | 2440*1220 |

2.5 | 2440*1220 |

3.0 | 2440*1220 |

4.0 | 2440*1220 |

5.0 | 2440*1220 |

6.0 | 2440*1220 |

Chemical composition of cold rolled SPCC coil:

C | ≤0.12 |

Mn | ≤0.50 |

P | ≤0.035 |

S | 0.025 |

Mechanical properties:

Yield Strength | ≥198 |

Tensile Strength | 315~430 |

Elongation | ≥33 |

Surface treatment:

The surface of SPCC in CNC fabrication is not protected and is easily oxidized when exposed to air, especially in a humid environment, causing dark red rust on the surface. It should be painted, electroplated or other protective measures should be taken during use.

The surface treatment methods that can be performed on cold-rolled SPCC plates are:

Plastic spraying

Silkscreen

Laser marking

Application areas:

Cold-rolled steel sheets have good properties, that is, through cold rolling, thinner and higher precision cold-rolled strips and steel plates can be obtained, with high straightness, high surface finish, clean and bright surface of cold-rolled steel sheets, easy coating and plating processing, many varieties and wide uses. At the same time, they have the characteristics of high stamping performance, no aging and low yield point. Therefore, cold-rolled steel sheets have a wide range of uses, mainly used in automobiles, printed iron drums, construction, building materials, bicycles and other industries. They are also the best choice for the production of organic coated steel sheets .

※ Some data comes from the Internet and is for reference only