Exploring the Realm of the Cheapest CNC Machining Co: The Intricacies of Pivot Shaft Production and the Impact of Patent Disputes

Introduction to the Cheapest CNC Machining Co

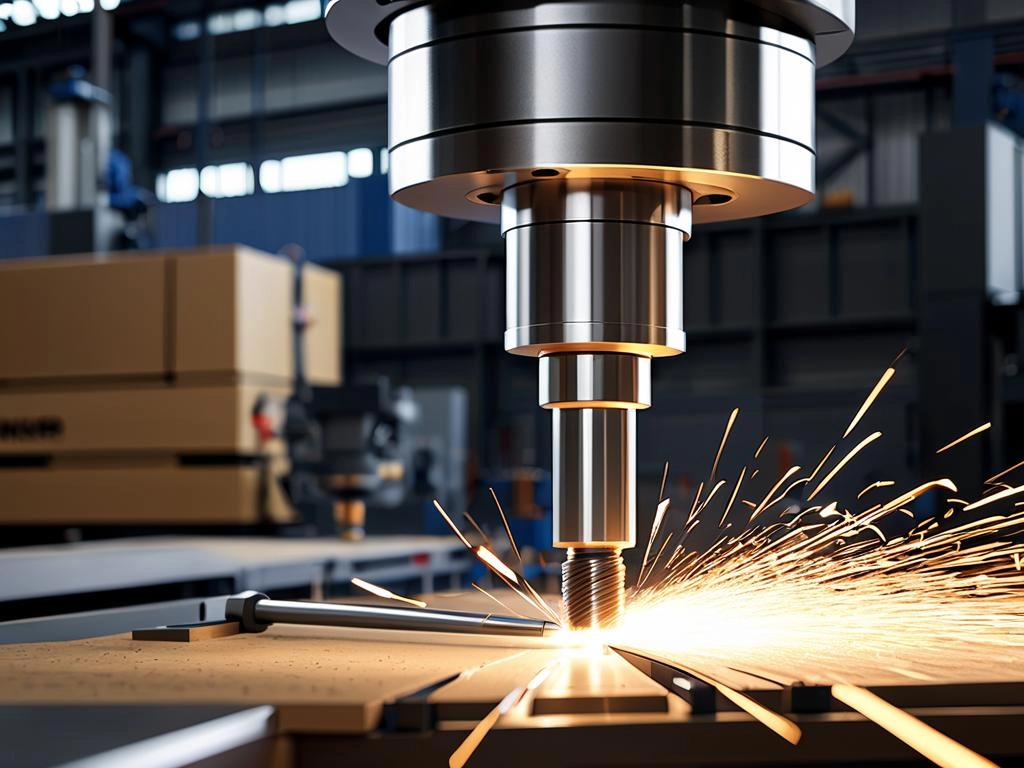

In the highly competitive world of manufacturing, finding the cheapest CNC machining company can be a game-changer for businesses looking to optimize their production costs without compromising on quality. The concept of a "cheapest CNC Machining co" doesn't simply imply the lowest price tag; it encompasses a combination of factors such as efficient processes, advanced technology, and skilled labor. These companies strive to offer cost-effective solutions to their clients by leveraging economies of scale and innovative manufacturing techniques.

Key Characteristics of the Cheapest CNC Machining Co

One of the primary characteristics of a cost-effective CNC machining company is its ability to invest in state-of-the-art machinery. This ensures high precision and accuracy in the production process, reducing the chances of errors and rework. Additionally, such companies often have a streamlined supply chain management system in place, enabling them to source raw materials at competitive prices. They also focus on continuous improvement and employee training to enhance productivity and efficiency.

Benefits of Choosing the Cheapest CNC Machining Co

Opting for the cheapest CNC machining company can bring several benefits to businesses. Firstly, it can significantly reduce production costs, allowing companies to offer more competitive prices in the market. This, in turn, can lead to increased market share and higher profits. Moreover, these companies often have the expertise and experience to handle complex projects, ensuring timely delivery and high-quality output. By partnering with a cost-effective CNC machining company, businesses can also free up their resources to focus on other core aspects of their operations.

The Significance of Pivot Shaft in Manufacturing

The pivot shaft is a crucial component in various mechanical systems. It serves as a rotational axis, allowing for smooth and precise movement of parts. In industries such as automotive, aerospace, and robotics, the quality and performance of the pivot shaft can have a significant impact on the overall functionality and reliability of the equipment. The manufacturing process of pivot shafts requires a high level of precision and expertise, as even the slightest deviation can lead to problems such as misalignment and premature wear.

Manufacturing Processes for Pivot Shafts

CNC machining is one of the most commonly used methods for manufacturing pivot shafts. This process involves the use of computer-controlled machines to remove material from a workpiece with high precision. The CNC machines can be programmed to produce pivot shafts with complex geometries and tight tolerances. Another popular manufacturing process is forging, which involves shaping the metal by applying compressive forces. Forging can result in a stronger and more durable pivot shaft, but it requires specialized equipment and expertise.

Quality Control in Pivot Shaft Production

To ensure the quality and reliability of pivot shafts, strict quality control measures are essential. This includes inspection of raw materials, monitoring of the manufacturing process, and final testing of the finished products. Advanced inspection techniques such as coordinate measuring machines (CMM) and non-destructive testing (NDT) can be used to detect any defects or deviations from the specified dimensions. Additionally, regular maintenance and calibration of the manufacturing equipment are necessary to maintain consistent quality.

The Complex World of Patent Disputes

Patent disputes are a common occurrence in the manufacturing industry, especially in the field of CNC machining. These disputes can arise due to various reasons, such as infringement of intellectual property rights, unauthorized use of patented technologies, or disputes over the ownership of inventions. Patent disputes can be time-consuming and costly, often resulting in legal battles that can have a significant impact on the involved parties.

Causes of Patent Disputes in CNC Machining

One of the main causes of patent disputes in CNC machining is the rapid pace of technological innovation. As new technologies and processes are developed, there is a higher likelihood of overlapping or conflicting intellectual property claims. Additionally, the globalization of the manufacturing industry has led to an increase in cross-border patent disputes, as companies operate in multiple jurisdictions with different patent laws and regulations.

Impact of Patent Disputes on the Cheapest CNC Machining Co

For the cheapest CNC machining company, patent disputes can have both direct and indirect impacts. Directly, they may face legal costs and potential damages if found to be infringing on someone else's patents. Indirectly, patent disputes can damage the company's reputation and brand image, leading to a loss of customers and business opportunities. Moreover, the uncertainty surrounding patent disputes can also affect the company's ability to invest in research and development and bring new products to the market.

Conclusion and Future Outlook

In conclusion, the concept of the cheapest CNC Machining co is not just about cost savings but also about delivering high-quality products and services. The production of pivot shafts requires precision and quality control to ensure their reliable performance. Meanwhile, patent disputes pose significant challenges to the industry, affecting both the innovation and competitiveness of companies. Looking ahead, it is crucial for CNC machining companies to stay updated with the latest technologies and patent laws to navigate the complex landscape successfully. By focusing on innovation, quality, and compliance, the cheapest CNC Machining co can continue to thrive in a highly competitive market.