Exploring the World of Industrial CNC Miling and Its Competitive Advantage in Toaster Slot Production: A Comprehensive Analysis

Introduction to Industrial CNC Miling

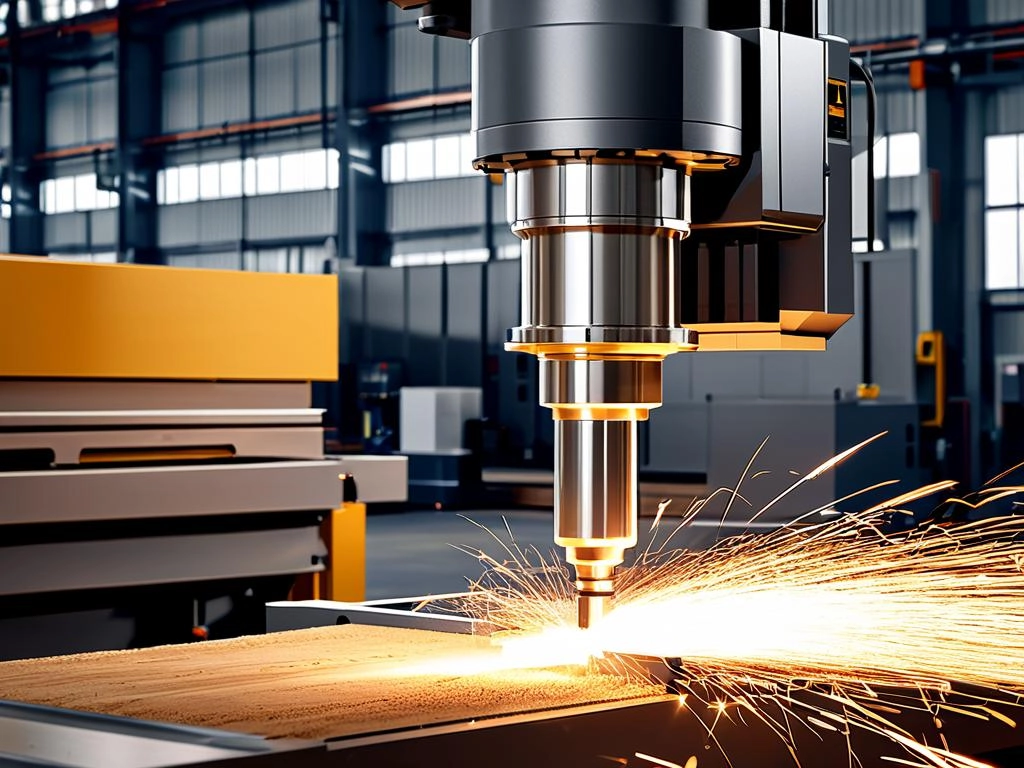

Industrial CNC milling is a revolutionary manufacturing process that has transformed the way various products are made. CNC, which stands for Computer Numerical Control, allows for precise and automated control of milling machines. This technology has opened up new possibilities in terms of accuracy, efficiency, and complexity in manufacturing.

The Basics of CNC Milling

At its core, CNC milling involves the use of computer programs to control the movement of cutting tools. These tools remove material from a workpiece to create the desired shape. The precision offered by CNC milling is unparalleled, as it can achieve tolerances in the micrometer range. This level of accuracy is crucial in industries where even the slightest deviation can lead to significant quality issues.

Advantages of Industrial CNC Miling

One of the key advantages of industrial CNC milling is its ability to produce complex shapes with high repeatability. Traditional milling methods often require skilled operators and are time-consuming, especially for intricate designs. With CNC milling, once the program is set up, the machine can produce identical parts with consistent quality. This not only saves time but also reduces the likelihood of human error.

Applications of Industrial CNC Miling

Industrial CNC milling finds applications in a wide range of industries. From aerospace and automotive to electronics and medical devices, CNC milling is used to manufacture components with high precision. For example, in the aerospace industry, CNC milling is used to produce engine parts and structural components that require strict adherence to specifications.

The Significance of Toaster Slot Manufacturing

The toaster slot, though seemingly a simple component, plays a crucial role in the functionality and user experience of a toaster. A well-designed and precisely manufactured toaster slot ensures even toasting and easy insertion and removal of bread slices.

Design Considerations for Toaster Slots

When designing toaster slots, factors such as the size, shape, and surface finish need to be carefully considered. The slots should be wide enough to accommodate different sizes of bread but not too wide that the bread falls through. The shape of the slot can also affect the heat distribution and toasting uniformity.

Manufacturing Challenges in Toaster Slot Production

Manufacturing toaster slots presents several challenges. Achieving the required precision and consistency in the slot dimensions can be difficult with traditional manufacturing methods. Additionally, ensuring a smooth surface finish is essential to prevent bread from sticking and to maintain the aesthetic appeal of the toaster.

The Role of Industrial CNC Miling in Toaster Slot Manufacturing

Industrial CNC milling offers a solution to the challenges faced in toaster slot manufacturing. The high precision and repeatability of CNC milling enable the production of toaster slots with accurate dimensions and a smooth surface finish. This ensures consistent toasting performance and a better user experience.

The Competitive Advantage of Industrial CNC Miling in Toaster Slot Production

In the highly competitive toaster market, manufacturers are constantly looking for ways to gain an edge. Industrial CNC milling provides several competitive advantages in toaster slot production.

Quality and Consistency

By using CNC milling, manufacturers can produce toaster slots with a high level of quality and consistency. This reduces the likelihood of defective products and improves customer satisfaction. Consistent quality also helps build a strong brand reputation, which is crucial in a competitive market.

Cost Efficiency

Although the initial investment in CNC milling equipment may be higher, the long-term cost savings are significant. CNC milling reduces labor costs as it requires less manual intervention. It also minimizes material waste due to its precision, resulting in lower production costs overall.

Flexibility and Customization

CNC milling allows for easy customization of toaster slots. Manufacturers can quickly adjust the design and dimensions of the slots to meet the specific requirements of different customers or market trends. This flexibility gives them a competitive advantage in a rapidly changing market.

Innovation and Design Freedom

The precision and capabilities of industrial CNC milling enable manufacturers to explore new and innovative designs for toaster slots. They can create unique shapes and features that enhance the functionality and aesthetics of the toaster, setting their products apart from the competition.

In conclusion, industrial CNC milling has a significant impact on toaster slot production. Its ability to provide high precision, quality, and cost efficiency gives manufacturers a competitive advantage in the market. As technology continues to advance, we can expect further improvements in CNC milling and its applications in the manufacturing industry.