Unveiling the World of CNC Turning Shops Search for Fan Blade Production with the Power of Cloud Control: A Comprehensive Guide

Understanding CNC Turning Shops Search

The Significance of CNC Turning Shops

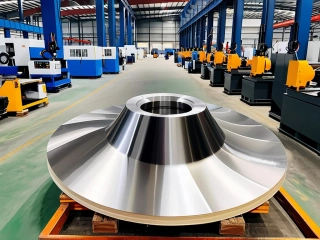

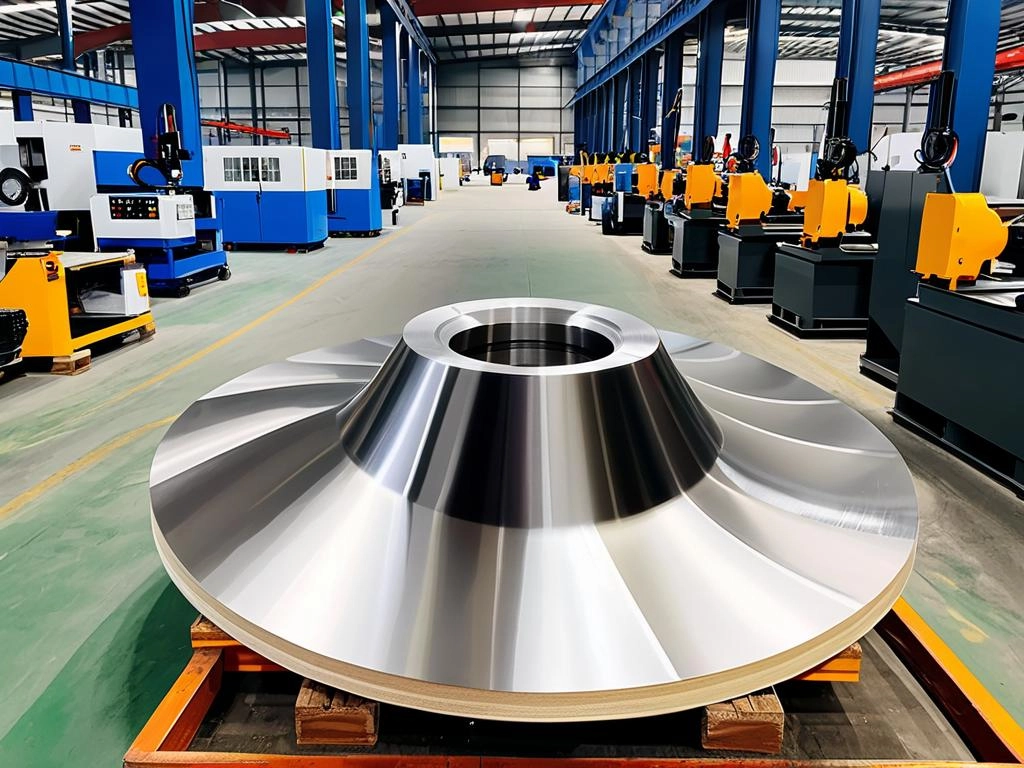

CNC turning shops play a crucial role in modern manufacturing. These specialized facilities are equipped with advanced computer numerical control (CNC) machines that can precisely shape and fabricate various components. In the context of fan blade production, CNC turning shops offer unparalleled accuracy and efficiency. They can transform raw materials into high-quality fan blades with tight tolerances, ensuring optimal performance and reliability.

How to Conduct an Effective CNC Turning Shops Search

When embarking on a CNC turning shops search, several factors need to be considered. Firstly, it's essential to assess the shop's capabilities and expertise. Look for shops that have experience in manufacturing fan blades specifically, as this indicates their familiarity with the unique requirements and challenges associated with this component. Additionally, consider the shop's equipment and technology. State-of-the-art CNC machines are more likely to produce superior results. Another crucial aspect is the shop's reputation and customer reviews. Positive feedback from previous clients is a good indication of their reliability and quality of work.

Benefits of Choosing the Right CNC Turning Shop

Selecting the right CNC turning shop can bring numerous benefits. For fan blade production, a reputable shop can ensure that the blades are manufactured to the highest standards. This leads to improved aerodynamic performance, reduced noise levels, and increased energy efficiency. Moreover, a reliable shop will also offer timely delivery, minimizing production delays and ensuring a smooth supply chain. Additionally, they may provide valuable design and engineering support, helping to optimize the fan blade design for better performance.

The Intricacies of Fan Blade Manufacturing

Design Considerations for Fan Blades

The design of fan blades is a complex process that involves multiple factors. Aerodynamics is a primary consideration, as the blade's shape and profile directly impact its performance. The angle of attack, blade curvature, and chord length all need to be carefully optimized to achieve maximum airflow and efficiency. Additionally, material selection is crucial. Fan blades need to be made from materials that can withstand the forces and stresses experienced during operation, while also being lightweight to minimize energy consumption.

Manufacturing Processes for Fan Blades

CNC turning is one of the key manufacturing processes used for fan blades. In this process, a rotating workpiece is gradually shaped by a cutting tool controlled by a computer program. This allows for precise control over the blade's dimensions and surface finish. Other processes such as milling, grinding, and polishing may also be used to further refine the blade's shape and surface quality. Quality control is essential throughout the manufacturing process to ensure that each fan blade meets the required specifications.

Quality Assurance in Fan Blade Production

To ensure the quality of fan blades, rigorous quality assurance measures are implemented. This includes dimensional inspection using precision measuring instruments to verify that the blade's dimensions are within the specified tolerances. Non-destructive testing techniques such as ultrasonic inspection may also be used to detect any internal defects. Surface finish inspection is another important aspect, as a smooth surface reduces drag and improves performance. By adhering to strict quality standards, manufacturers can produce fan blades that are reliable and long-lasting.

The Role of Cloud Control in CNC Turning Shops

Enhancing Production Efficiency with Cloud Control

Cloud control technology has revolutionized the way CNC turning shops operate. By connecting CNC machines to the cloud, manufacturers can remotely monitor and control the production process. This allows for real-time adjustments and optimization, improving production efficiency. For example, operators can monitor machine performance, tool wear, and production progress from a central control room or even from a mobile device. This enables them to quickly identify and address any issues, reducing downtime and increasing productivity.

Data Management and Analytics in the Cloud

Cloud control also enables efficient data management and analytics. CNC machines generate a vast amount of data during the production process, including information about cutting parameters, tool life, and quality metrics. By storing this data in the cloud, manufacturers can analyze it to gain valuable insights into production trends and performance. This data can be used to optimize production processes, predict maintenance needs, and improve product quality. For instance, by analyzing historical data on tool wear, manufacturers can determine the optimal tool replacement intervals, reducing tool costs and improving production efficiency.

Cloud-Based Collaboration and Communication

Cloud control facilitates seamless collaboration and communication within CNC turning shops and across the supply chain. Different departments and teams can access and share production data in real-time, enabling better coordination and decision-making. For example, design engineers can communicate directly with production operators to make design modifications based on real-time production feedback. Additionally, cloud-based collaboration platforms allow suppliers and customers to stay informed about production progress, ensuring timely delivery and customer satisfaction.

Conclusion and Future Outlook

Summary of Key Points

In conclusion, the search for the right CNC turning shops is crucial for high-quality fan blade production. These shops offer the expertise and capabilities needed to manufacture precision components. Fan blade manufacturing involves complex design and manufacturing processes, with quality assurance being of utmost importance. Cloud control technology has emerged as a powerful tool, enhancing production efficiency, enabling data management and analytics, and facilitating collaboration. By leveraging these technologies and selecting the right CNC turning shop, manufacturers can produce superior fan blades that meet the demands of various industries.

Future Trends in CNC Turning and Fan Blade Production

Looking ahead, we can expect further advancements in CNC turning technology and cloud control. The integration of artificial intelligence and machine learning algorithms into CNC machines will enable even more intelligent and autonomous production processes. For fan blade production, this could lead to the development of more efficient blade designs and manufacturing techniques. Additionally, the increasing demand for sustainable manufacturing practices will drive the adoption of eco-friendly materials and processes in CNC turning shops. Overall, the future of CNC turning and fan blade production looks promising, with continued innovation and improvement on the horizon.