Discover the Top 10 CNC Turning Companies for High-Quality Pivot Shaft Production and Exceptional Product Design

0.00

(2)4.5

SKU:CNCS0068

Mpn:CNCM0068

Category:Machining Parts

* The data is open source, not security confidential file from client.

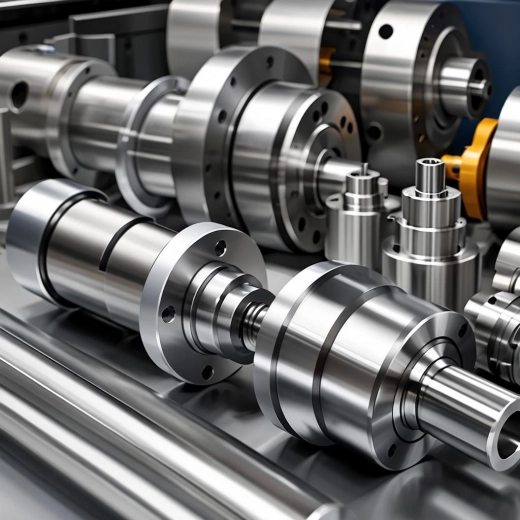

Introduction to CNC Turning

CNC turning is a revolutionary manufacturing process that has transformed the way precision components are produced. It involves the use of computer numerical control (CNC) systems to automate the turning of raw materials into highly accurate and complex parts. In the context of pivot shafts, CNC turning offers unparalleled precision and consistency, ensuring that these critical components meet the exact specifications required for optimal performance.

The Importance of Precision in Pivot Shaft Manufacturing

Pivot shafts play a crucial role in various mechanical systems, from automotive applications to industrial machinery. Even the slightest deviation in their dimensions or surface finish can lead to significant performance issues, such as increased wear, reduced efficiency, and compromised safety. CNC turning companies with advanced technology and expertise are able to achieve the tight tolerances necessary to produce pivot shafts of the highest quality.

Advanced CNC Turning Technologies for Pivot Shafts

Modern CNC turning machines are equipped with state-of-the-art features such as multi-axis capabilities, high-speed spindles, and advanced tooling systems. These technologies enable manufacturers to produce pivot shafts with complex geometries and superior surface finishes in a highly efficient manner. For example, multi-axis turning allows for the creation of intricate shapes and contours in a single setup, reducing production time and improving accuracy.

Top 10 CNC Turning Companies

Company 1: Excellence in Precision Engineering

This company has a long-standing reputation for delivering top-notch CNC turning services. Their team of highly skilled engineers and technicians utilizes the latest CNC technology to produce pivot shafts with exceptional precision. They also offer comprehensive product design support, working closely with clients to develop custom solutions that meet their specific requirements.

Company 2: Innovators in Product Design

With a focus on innovation, this CNC turning company is constantly pushing the boundaries of what is possible in pivot shaft manufacturing. They invest heavily in research and development to develop new and improved manufacturing processes and product designs. Their pivot shafts are known for their high performance and reliability, making them a popular choice among leading industries.

Company 3: High-Quality Production at Competitive Prices

This company combines advanced CNC turning technology with efficient production processes to offer high-quality pivot shafts at competitive prices. They have a strict quality control system in place to ensure that every product meets the highest standards. Their commitment to customer satisfaction has earned them a loyal client base.

Company 4: Specializing in Custom Pivot Shafts

If you need custom pivot shafts tailored to your unique requirements, this company is the ideal choice. They have extensive experience in designing and manufacturing custom components, working closely with clients to understand their needs and deliver solutions that exceed expectations. Their attention to detail and commitment to quality make them a trusted partner in the industry.

Company 5: Industry-Leading Expertise

With decades of experience in CNC turning, this company has established itself as an industry leader. Their expertise in pivot shaft manufacturing is unmatched, and they have a proven track record of delivering high-quality products to a wide range of industries. They also offer value-added services such as assembly and testing, providing a complete solution to their clients.

The Role of Product Design in Pivot Shaft Manufacturing

Design for Performance

Product design is a critical aspect of pivot shaft manufacturing. A well-designed pivot shaft not only meets the functional requirements but also enhances the overall performance of the mechanical system. Designers need to consider factors such as load-bearing capacity, rotational speed, and environmental conditions to ensure that the pivot shaft can withstand the demands of its intended application.

Design for Manufacturability

In addition to performance, product design also needs to take into account manufacturability. A design that is difficult or impossible to manufacture using CNC turning processes can lead to increased costs and production delays. Designers must work closely with CNC turning companies to develop designs that are optimized for manufacturing, taking advantage of the capabilities of the CNC machines.

Design for Aesthetics

While functionality is the primary concern in pivot shaft design, aesthetics also play a role. In some applications, such as consumer products or high-end machinery, the appearance of the pivot shaft can be an important factor. Designers can incorporate aesthetic elements into the design without compromising performance, creating pivot shafts that are both functional and visually appealing.

Future Trends in CNC Turning and Pivot Shaft Manufacturing

Automation and Industry 4.0

The future of CNC turning is likely to be dominated by automation and the integration of Industry 4.0 technologies. Smart factories with interconnected machines and real-time data analytics will enable manufacturers to optimize production processes, improve quality control, and reduce downtime. This will lead to even higher levels of efficiency and productivity in pivot shaft manufacturing.

Advanced Materials and Coatings

As the demand for higher performance pivot shafts increases, the use of advanced materials and coatings will become more prevalent. Materials such as titanium alloys and high-strength steels offer superior mechanical properties, while advanced coatings can provide enhanced wear resistance and corrosion protection. CNC turning companies will need to invest in the necessary equipment and expertise to work with these materials.

Additive Manufacturing Integration

Additive manufacturing, also known as 3D printing, is expected to play a growing role in pivot shaft manufacturing. While CNC turning is well-suited for producing high-precision components, additive manufacturing can be used to create complex geometries and internal structures that are difficult or impossible to achieve with traditional machining methods. The integration of these two manufacturing processes will open up new possibilities for pivot shaft design and production.