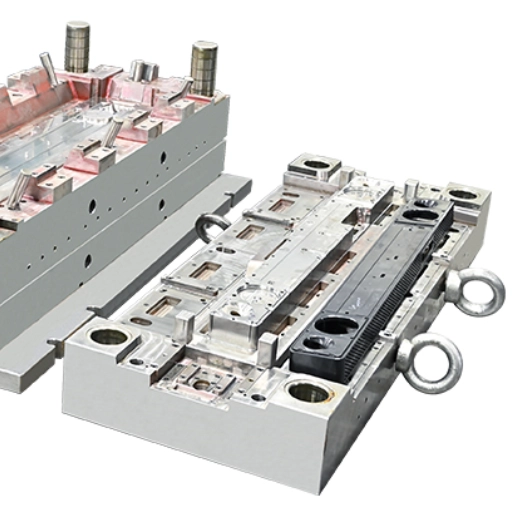

Injection mould development

0.00

SKU:CNCS0097

Mpn:CNCM0097

Category:Molding Tooling Parts

* The data is open source, not security confidential file from client.

With the business philosophy of "integrity, win-win, and pioneering", we create a good corporate business environment, and create more and greater value for you with a new management model, perfect technology, thoughtful service, and excellent quality.

Craftsman inheritance, hard work

Project objectives:

1. Design and manufacture to meet customer needsInjection moulds;

2. Ensure quality and reliability of the mould;

3. Complete the mould development within the specified time and ensure smooth mould trial and mass production of the mould.

Project plan:

1. Mould Design:

Detailed analysis of product drawings provided by the customer to determine the design plan of the mould. Factors such as the structure, material, size, and molding process of the product are fully taken into account in the design process.

2. Mould material selection:

Choose the appropriate mould material according to the mould usage requirements and the material characteristics of the product.

3. Mold processing:

Using advanced processing equipment and processes, high-precision processing of the mold is carried out to ensure dimensional accuracy and surface quality of the mold.

4. Mold trial and adjustment:

After the mold manufacturing is completed, the mold trial is carried out and the mold is adjusted according to the mold trial results to ensure that the mold can produce products that meet the customer's requirements.

5. Mass production:

After the adjustment of the mold is completed, mass production is carried out to ensure the production efficiency and product quality of the mold.

QC:

1. Strict quality control measures are implemented to ensure the quality and reliability of the moulds in such aspects as mould design, material selection, processing and mold trial.

2. Strict inspection and testing of the key components and dimensions of the mould to ensure that the mould meets the requirements of the customer.

Project team:

A professional team of experienced mould designers, craftsmen, processors and quality control personnel will be responsible for the implementation of this project. Team members will develop their expertise and skills to the full to ensure the smooth implementation and successful completion of the project.

Project progress:

Detailed project progress plans will be drawn up in accordance with the requirements of the client and the specific circumstances of the project, and will be carried out in strict accordance with the plan. The progress of the project will be regularly reported to the client in order to ensure the smooth progress of the project.

With professional technology, efficient team and perfect service, we will provide our customers with high quality and high efficiencyInjection mouldsDevelopment services. We look forward to working with our clients to jointly promote the successful implementation of the project.