Learning And Sharing On Processing And Preparation Methods Of Magnesium Alloy Materials

In order to meet the needs of the national defense industry and national economic development, more than 70% of magnesium raw materials are processed into magnesium alloy materials. Magnesium alloy materials mainly include magnesium alloy forming materials and magnesium alloy casting materials. Plastic processing materials are divided into plates, strips, strips, tubes, rods and other materials.

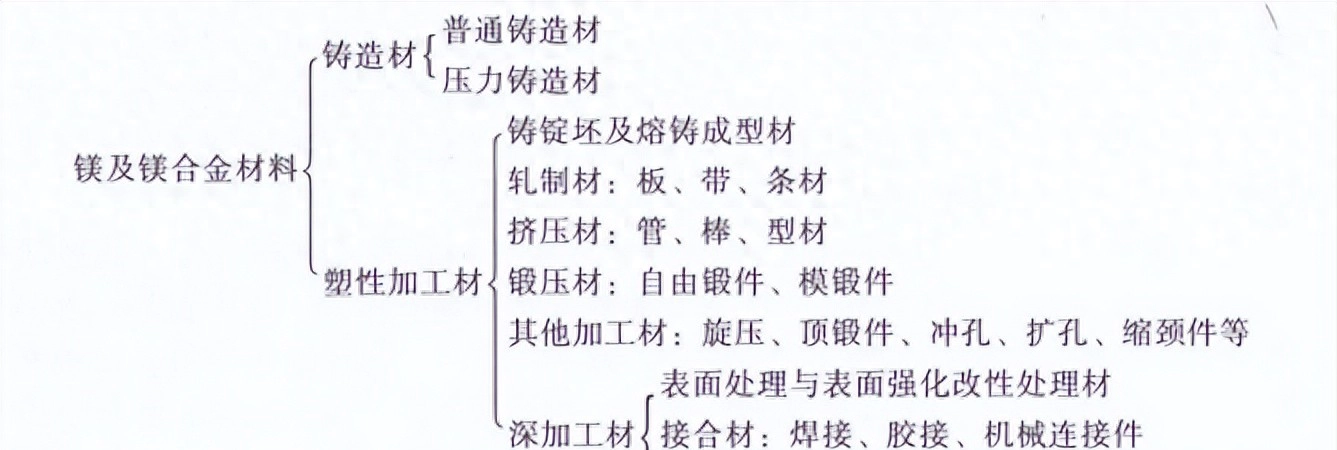

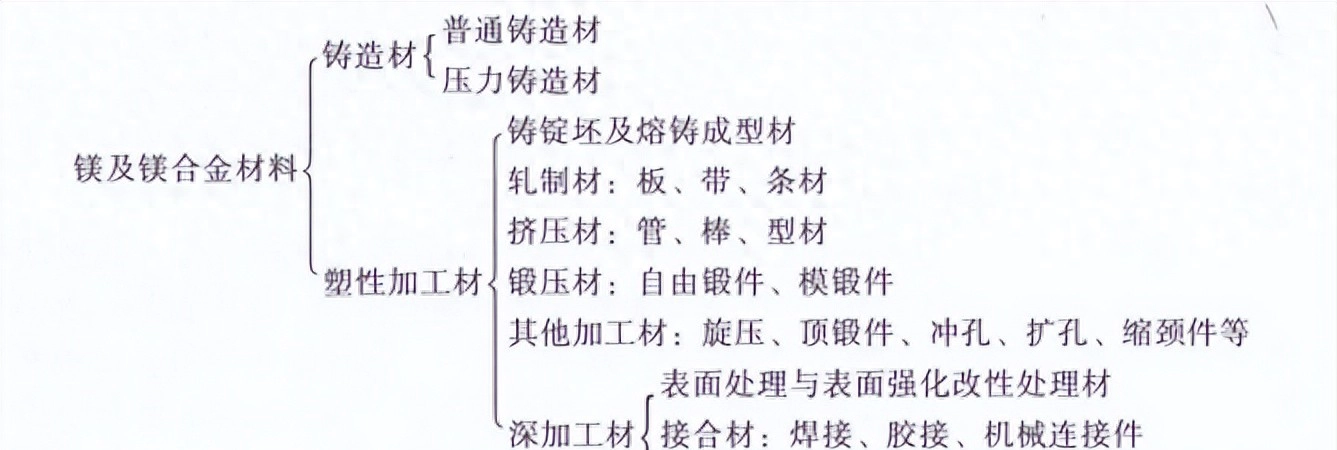

Magnesium and magnesium alloy material classification

At present, in terms of metal forming processes (methods), most of them can be used for the forming of magnesium and magnesium alloys, the most important of which include casting methods, plastic forming methods, deep processing methods, etc. Among them, casting methods can be subdivided into: sand casting, metal mold casting, low pressure casting, high pressure casting and smelting casting. Plastic processing methods can be divided into extrusion, forging, stamping and rolling.

Sand casting method:> Suitable for producing castings with complex shapes and large volumes. The quality of such castings is very good, but the production efficiency is not good.

Metal mold casting method:> Suitable for producing castings with complex shapes and large volumes. Castings have excellent quality and are widely used, but the process is complex and the production cost is quite high.

Low pressure casting method:> Suitable for producing medium-volume castings with complex shapes, high quality and low cost.

High pressure casting method:> It is suitable for the production of small and medium-sized castings with high requirements on size and shape accuracy. Its casting products have stable quality and large production batches. Production costs are lower compared to other casting methods. It also has the advantages of high precision, short production cycle, and long die-casting mold life. The advantage is that it is the most widely used processing and forming process for magnesium and magnesium alloys.

Smelting and casting method:> Suitable for the production of castings that require the most precise dimensions and very complex shapes as well as product structure and performance requirements. The quality of the castings is good, but the cost is high. In addition, this smelting and casting method can also be used to specifically prepare round, flat or special-shaped ingots of deformed magnesium alloys.

Extrusion molding method:> Suitable for producing magnesium and magnesium alloy tubes, rods and profiles. Its products are characterized by high performance and low cost. It is suitable for manufacturing products of multiple varieties, small batches and large lengths, especially for the extrusion production of magnesium alloys with low plasticity and difficult to deform.

Forging forming method:> It is suitable for producing parts with relatively complex shapes, and its products have excellent performance, high quality and moderate cost.

Stamping forming method:> It is suitable for producing parts with simple shapes, good product quality, high performance and low cost. It is often used for the secondary or tertiary forming of magnesium and magnesium alloy plates, strips and certain profiles and pipes.

Roll forming method:> It is suitable for producing magnesium and magnesium alloy plates and strips with large batches, wide uses and strong versatility. The width and thickness of the board and strip can be changed, and the length can be adjusted. This is an excellent magnesium alloy processing method. However, this method requires huge investment, long construction period, and difficulty in producing plastic magnesium alloy plates.

In addition, the deep processing of magnesium and magnesium alloy materials also includes surface treatment, connection, cold working and machining. Suitable for secondary or tertiary molding of cast and machined materials as well as the production of parts.