Stainless Steel Surface Treatment Technology And Common Problems In Processing

Our common stainless steel surface treatment process has many applications in interior decoration. In this issue, we focus on explaining to you the following two types of stainless steel application issues.

1. In addition to brushed/mirror surface, what other surface treatments are available for stainless steel? 2. How to ensure flatness when using stainless steel veneers? What is the limit of stainless steel edging?

What are the surface treatment processes for stainless steel?>

Our common stainless steel surface treatment processes: wire drawing, mirror surface, sandblasting, titanium plating, etching, anti-fingerprint, etc., have many wonderful applications in interior decoration:

1. Brushed (frosted)>

Usually, the surface of stainless steel is processed by mechanical friction to produce straight lines (also called frosted lines), including wire drawing, texture, corrugation, etc.

brushed stainless steel

2.Mirror surface>

Polishing and grinding equipment is used to use high-quality oilstone, diamond abrasive paste and different grades of sandpaper for rough grinding, medium grinding and fine grinding to obtain a bright surface effect.

Balcony mirror stainless steel honeycomb panel ceiling

Processing quality standards: no sand lines, pockmarks (orange peel lines), the surface should be smooth, there should be no depressions, bulges or undulating wavy surfaces (mirror roughness), and there should be no residues, blisters, scars, impurity spots or rough surfaces. of bruises. Metal CNC machining, no scratches, brightness reaches 8K, precision polished mirror brightness exceeds 8K.

Definition of terms: The "8" in 8K refers to the proportion of alloy components, and "K" refers to the level of reflectivity after polishing (K level is the specular reflection level). The 8K mirror is also a chrome-nickel alloy. The mirror grade is reflected in the steel.

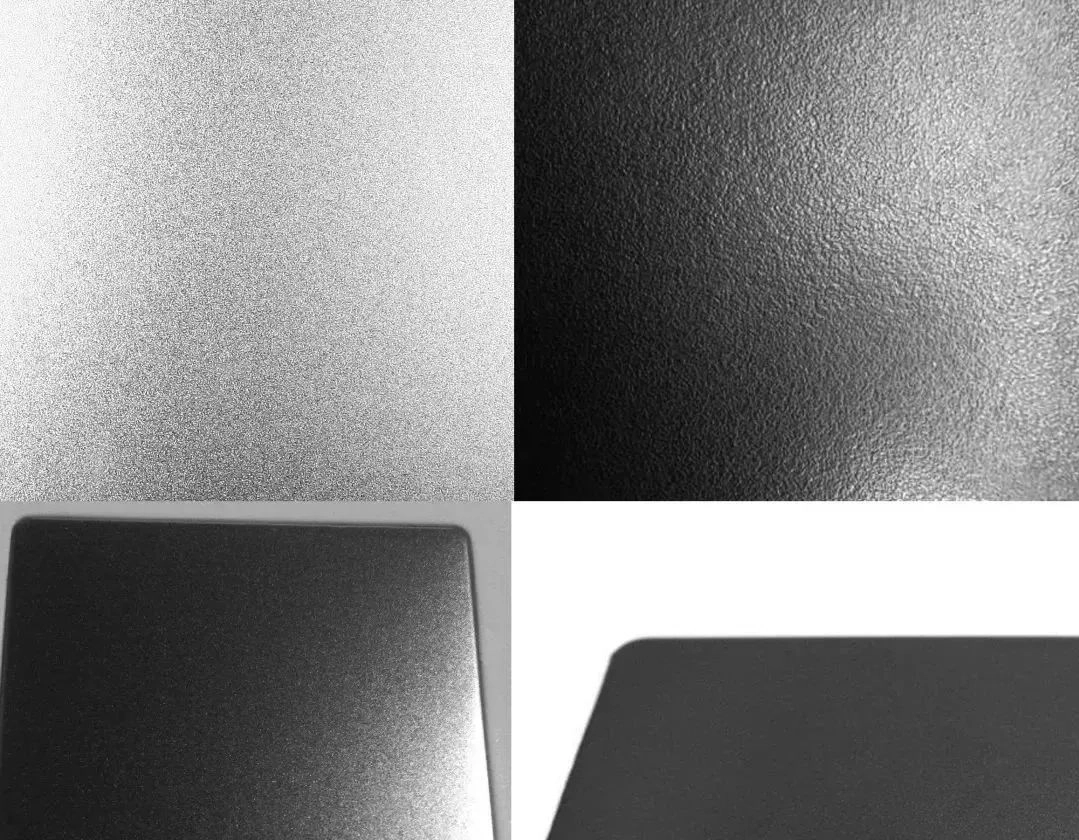

3.> sandblasting

Using compressed air as power, a high-speed spray beam is formed, and the spray material (quartz sand, emery) is sprayed onto the surface of the workpiece to be processed at high speed, so that the board surface presents a fine bead-like sand surface, forming a unique decorative effect.

sandblasted stainless steel

4.Etching>

The process principle of chemical etching pattern text on the surface of stainless steel is to cover the unetched part of the surface with a special anti-corrosion layer to shield the acid so that the acid can only contact the surface of this part for etching, and the etching patterns and patterns can be realized from the surface. Purpose of the text.

etched stainless steel

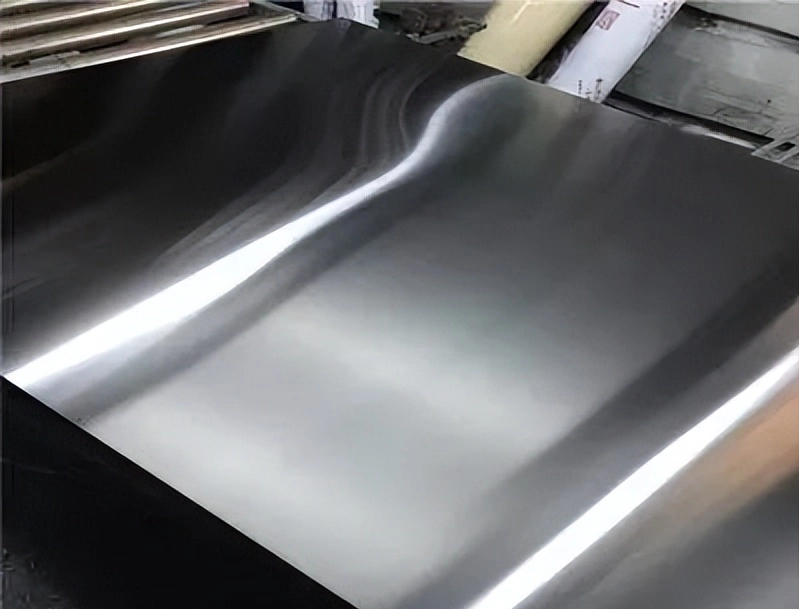

How to ensure flatness when using stainless steel veneers?>

stainless steel plate

1> . Flatness problems commonly encountered in stainless steel construction>

When the stainless steel veneer area is too large (more than 1 square meter), the surface will be uneven due to the poor stiffness of the stainless steel itself.

During project construction, it is recommended to use stainless steel with a thickness of ≥1.2mm. The larger the area, the thicker the thickness; otherwise, the slope will be uneven, resulting in poor overall appearance of the panel and other consequences.

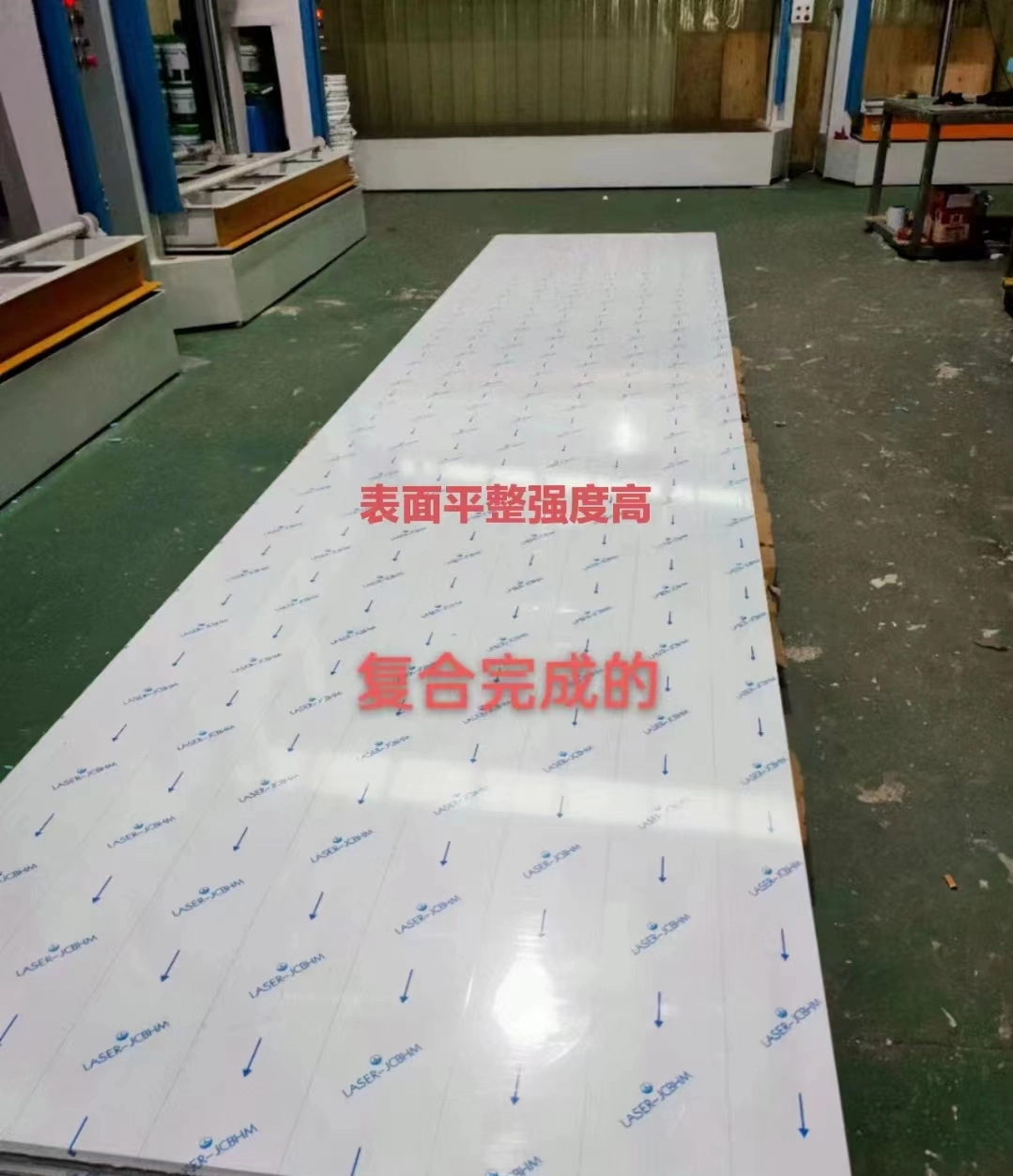

When the flatness requirements of stainless steel are high, stainless steel honeycomb panels can be used for honeycomb composite processing to ensure the flatness of the panels.

Composite stainless steel honeycomb panel

2. What is the hemming limit for stainless steel processing?>

The conventional thickness range of stainless steel we commonly use in decoration is usually between 0.5~3mm.

The surface of stainless steel less than 0.5mm is easily corrugated, causing uneven surfaces; if it is greater than 3mm, it will increase the weight of the stainless steel, increase the difficulty of construction, and waste unnecessary materials.

When processing and curling stainless steel, the critical value of stainless steel curling with a thickness of 1.2mm can be made into a thickness of 3mm.

However, it is not recommended to use this method to make 3mm thick sealing strips in general projects. It's unstable. All you need is a 3mm thick band of pure stainless steel.