One Product Covers 300 Application Conditions? Huarui Precision’s 2025 New Products Have Many Highlights

The end of the year is approaching, and looking back at 2024, there are ups and downs but also fruitful results. December 20, 2024, "Sinovel Precision 2025 New Product Launch and Win-Win Strategic Development Seminar"> Held grandly in Zhuzhou. Colleagues in the tool industry, experts and professors from colleges and universities, user representatives, and industry media from all over the country gathered together to count the harvest of the year, discuss future development, and witness the release of Sinovel Wind Power's major new products in 2025. Full live coverage of metal processing (Click here to watch the replay)> .

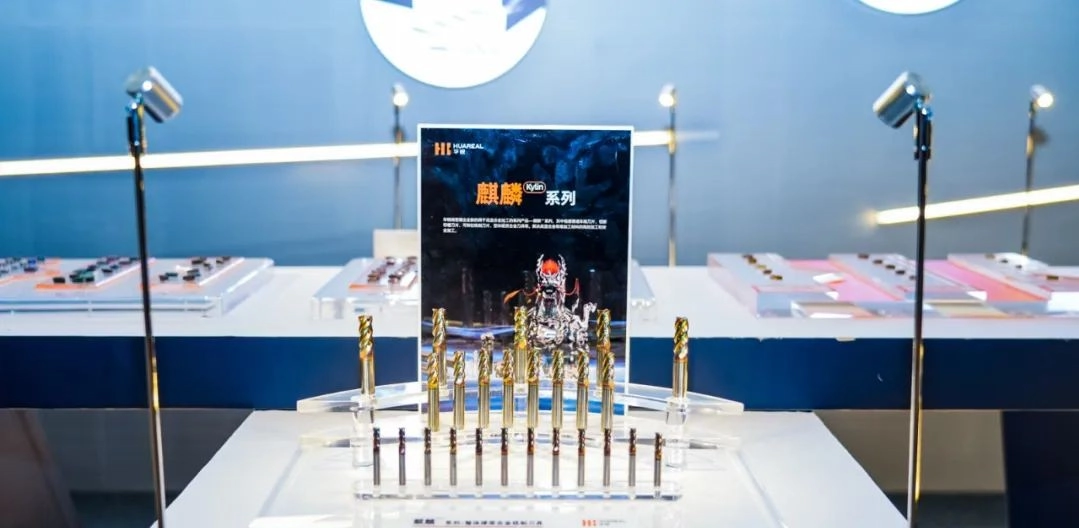

Ding Guofeng, deputy general manager of Huarui Precision Industry> First of all, I would like to extend a warm welcome to all the guests. Facing the wave of intelligent manufacturing, Huarui Precision always maintains firm belief and keeps making progress. The new products such as Kirin series and U series solid milling cutters launched this time have excellent cutting performance and I believe they will bring more value and competitive advantages to everyone. Huarui Precision will, as always, take innovation as its wing and ingenuity as its rudder, and strive to create good products with advanced industry, advanced technology, stable quality and affordable price, and continue to prove Huarui Precision's innovation ability and hard power as a national brand of cutting tools in China.

Ding Guofeng, Deputy General Manager of Huarui Precision Industry

Tian Liang, Secretary General of China Machinery Industry Metal Cutting Tool Technology Association> He said in his speech that my country's CNC tool industry is moving towards a new stage of high-quality development with unprecedented courage and determination. As a leading company in the domestic tool industry, Huarui Precision not only actively responds to national policies, improves product quality, promotes the application of intelligent manufacturing technology in the industry, but also continues to enter the global market from a market perspective and pave the way for the domestic tool industry. Cutting tools go overseas. The China Tool Association has always been committed to promoting the healthy development and technological progress of the industry. We also look forward to exploring new technologies and new models with enterprises, providing core strength for the prosperity of my country's manufacturing industry, and contributing to promoting China's knife industry to move towards the mid-to-high end of the global value chain. Make new and greater contributions.

Tian Liang Secretary General of China Machinery Industry Metal Cutting Tool Technology Association

Strategic planning under the new situation>

Xiao Xukai, chairman of Huarui Precision, fondly recalled the development history of Huarui Precision since its establishment: from a rented 400-square-meter factory to today's smart factory; from a start-up capital of 2 million to officially listing on the Science and Technology Innovation Board in 2021; from two old people and a group of young people. Under the current "teaching and educating" system, three generations of talents, old, middle and young, have emerged. It’s exciting and high-spirited, but it also has its ups and downs. These are the epitome of Huarui Precision’s innovative development.

Xiao Xukai, Chairman of Huarui Precision Industry

At present, Huarui Precision has a first-class CNC blade production line, and has formed a relatively complete product technology system for carbide CNC tools such as turning, milling, and drilling; it also has a complete overall hard tool production line, covering general-purpose milling cutters. , general drill bit series, special milling cutters for quenched steel processing, special milling cutters for difficult-to-machine materials, new 3C tools, etc.; it also has a highly automated and information-based CNC cutter body manufacturing factory. The automated line products achieve 100% online testing and can provide users with standard cutterheads and round handle knives. Bars, shallow hole drills and non-standard customized products.

In the future, Sinovel Wind Power Precision will continue to bring customers the ultimate products, ultimate services, overall solutions, tool service outsourcing, etc. to reduce costs and increase efficiency, contribute Sinovel Wind Power's strength to the technological progress of the industry, and strive to become a respected company. enterprise.

New product release>

Kirin series high temperature alloy processing tools>

At the new product launch conference Gao Jiangxiong, deputy general manager of Huarui Precision Industry> For the first time, Kirin series high-temperature alloy processing tools are introduced> . With the increasing demand for high-temperature alloys in aerospace, energy, chemical and other industries, the high-performance and high-precision tools required for high-temperature alloy processing have increasingly broad application prospects. In view of the difficulties in processing high-temperature alloys, the Sinovel Precision R&D team has successively carried out research on the adaptability of cemented carbide tools, the high-temperature performance degradation mechanism of base materials, and the collaborative regulation mechanism of high-performance nanocrystalline coatings. After 2 years, a variety of high-temperature alloys were finally developed. Alloy machining tools.

Gao Jiangxiong, Deputy General Manager of Huarui Precision Industry

Kirin series products include indexable turning tools, cutting and grooving tools, indexable milling cutters, solid carbide milling cutters, etc., dedicated to solving the efficient and safe processing of difficult-to-machine materials such as high-temperature alloys. Aerospace industry.

1.Kirin series turning tools>

1) New turning material,>

The new grade system for difficult-to-machine materials such as high-temperature alloys solves the problems of long service life and high safety of high-temperature alloy turning inserts.

: High wear resistance class for difficult-to-machine materials>

: General material for turning difficult-to-machine materials>

2) Kirin series turning processing geometries-SF, SM>

SF finishing geometry> :

SM semi-finishing-roughing geometry> :

2.Kirin series cutting and grooving inserts>

The newly launched single-edged square head grooving cutter HCMA series and single-edged round head grooving cutter HPMA series blades have complete specifications and strong versatility. It meets the processing needs of difficult-to-machine materials such as grooving, traversing and profiling, and effectively meets the multiple needs of chip control, surface quality and long service life.

ST: Cutting/grooving/turning geometries>

SR: Copy cutting geometry>

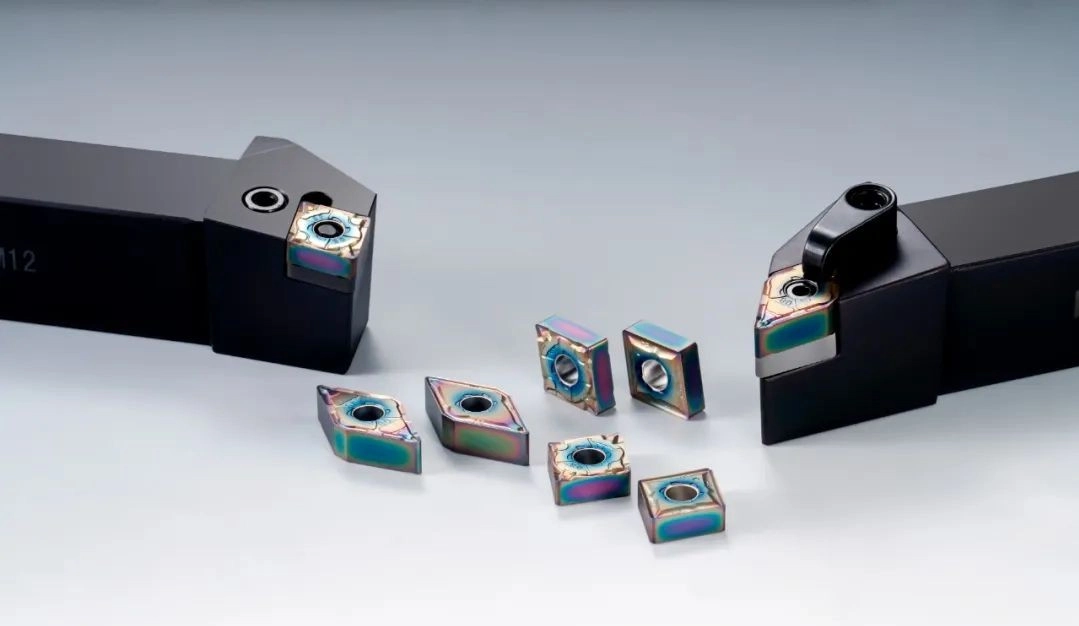

3. Kirin series indexable milling inserts>

It adopts a newly upgraded grade and matches the company's various indexable milling inserts to meet the needs of various processes such as high-temperature alloy flat shoulder milling and cavity milling, achieving the dual requirements of long life and safety.

High temperature alloy milling high wear-resistant grade> :

parts turning series>

Liu Zhilin, General Manager of Huarui Precision Turning Product Line> ReleaseNew turning products facing the automation trend> . The current industry automation development trend has put forward more stringent requirements for cutting tools in terms of high speed, high precision, good chip control, and stability. Huarui Precision closely follows market demand and develops high-speed and high-precision turning tools for the automotive industry and precision grinding tools for emerging industries.

Liu Zhilin, General Manager of Huarui Precision Turning Product Line

Precision small parts turning production line> Further diversification, now has a full range of products such as cylindrical turning, internal hole turning, shallow groove processing, thread cutting, backsweep processing, etc., to meet various needs for small parts turning processing.

There are cermet and carbide grades to choose from, suitable for the processing requirements of different materials.

It has strong non-standard development capabilities and can customize various types of small parts processing turning inserts.

New U series solid carbide milling cutter>

Qu Zhihua, General Manager of Huarui Precision Hardware Division> Grand release of new U series solid carbide milling cutters> . "U" is the first letter of "Ultra", meaning "Ultra Universal"> In response to the many problems that tool users have in procurement, cost, production, process management, etc., the U series helps users reduce usage costs and improve processing efficiency with its strong versatility and cutting performance.

As a new series of products integrating ultra-versatile and ultra-high performance, U series carbide end mills have a wide range of products, including flat end mills, arc milling cutters, ball end mills, etc. Can fully cover 300+ application conditions> , for 10 material groups such as steel, cast iron, stainless steel and titanium alloys> , three cooling methods: air cooling, water cooling, oil cooling> Excellent performance is achieved under all processing conditions.

On the afternoon of the 20th, experts from aerospace, robotics and other industries as well as well-known professors from universities gave professional sharing sessions to discuss new developments in the tool industry.

Cao Xuelei, President of Metal Processing Magazine of the Institute of Machinery Industry Information> In his opening speech, he said that the progress of cutting technology is closely related to the innovation of tool technology. Throughout the international tool giants, they all continue to focus on the research and development of new technologies and new products. In recent years, the domestic tool industry has achieved fruitful results in innovative development. Not only is its domestic market share increasing year by year, it is also playing an increasingly important role in the global manufacturing industry. As an outstanding representative of domestic tool companies, Huarui Precision has been engaged in carbide CNC cutting tools for 17 years. Focusing on R&D innovation, conquering core technologies, and launching many efficient and high-quality tool products. Looking to the future, tool companies not only need to concentrate on research and development and build core competitiveness through independent innovation, but also hope that user companies and tool companies will work closely together to make progress together and create new momentum for industry development.

Cao Xuelei, President of Metal Processing Magazine, Mechanical Industry Information Research Institute

Wang Guangping, Secretary-General of the National Defense Science and Technology Industry Efficient CNC Machining Innovation Center, Chief Technical Expert of Aviation Industry Corporation of China, and Assistant Chief Engineer of Changhe Aircraft Industry (Group) Co., Ltd.> Helicopter manufacturing technology and typical parts CNC machining tools were shared. From the user's perspective, the development needs of related cutting tools are introduced for typical parts such as fuselage structure, landing gear, propeller hub, etc.

Wang Guangping, Secretary General of the National Defense Science and Technology Industry Efficient CNC Machining Innovation Center, Chief Technical Expert of Aviation Industry Corporation of China, Assistant Chief Engineer of Changhe Aircraft Industry (Group) Co., Ltd.

Hu Yuqing, director and senior researcher of the Robotics Division of Ningbo Industrial Internet Research Institute> He shared the practice and prospects of robots and intelligent manufacturing, and summarized the implementation approaches of intelligent manufacturing and its significance to industry innovation based on years of practical experience.

Hu Yuqing Director and Senior Researcher of Robotics Division of Ningbo Industrial Internet Research Institute

He Yun, professor and doctoral supervisor at East China University of Science and Technology> The blade geometry and tool structure design based on edge guidance were elaborated, the edge guidance cutting excitation was introduced, and the research and application results of the new U-drill insert geometry design and large-scale threading cutterhead design were shared.

He Yun, professor and doctoral supervisor at East China University of Science and Technology

Peng Ruitao, professor, doctoral supervisor, director of the Engineering Teaching Department of Xiangtan University, and outstanding youth of Hunan Province> He shared the school-enterprise cooperation and innovative research results with Huarui Precision on the theme of integration of industry and education, integration of science and education, and promoting high-quality development of Huarui.

Peng Ruitao, professor of Xiangtan University, doctoral supervisor, director of the Engineering Teaching Department, and outstanding youth of Hunan Province

The day's meeting came to an end as the representatives visited Huarui Precision Intelligent Chemical Factory. On this day, everyone not only saw the distinctive new products in front of the stage, but also learned about the hard work behind the scenes in research and development, capital and equipment investment, talent recruitment and training, and user demand research over the years. School-enterprise cooperation is promoted. We have reason to believe that Sinovel Wind Power Precision will continue to bring more advanced new products and new technologies, build Sinovel Wind Power’s strength with innovation, and write a glorious chapter with strength.