What Is A CNC Precision Machining Center?

The term CNC stands for “computer CNC”, and CNC machining is defined as a subtractive manufacturing process that typically uses computer controls and machine tools to remove layers of material from stock parts (called blanks or workpieces) and produce custom designed parts. In order to change the properties of the steel and facilitate processing to increase the strength or hardness of the finished product, steel workpieces are usually treated before and after CNC treatment.

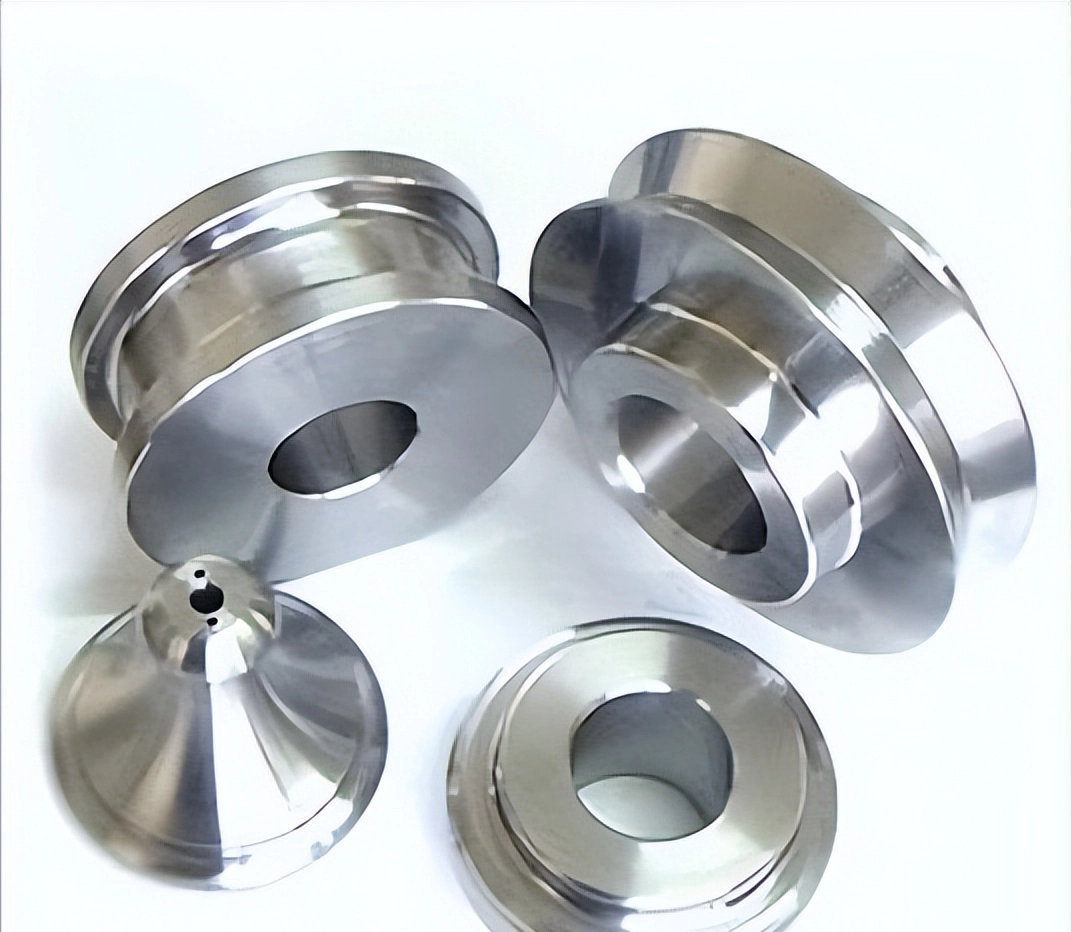

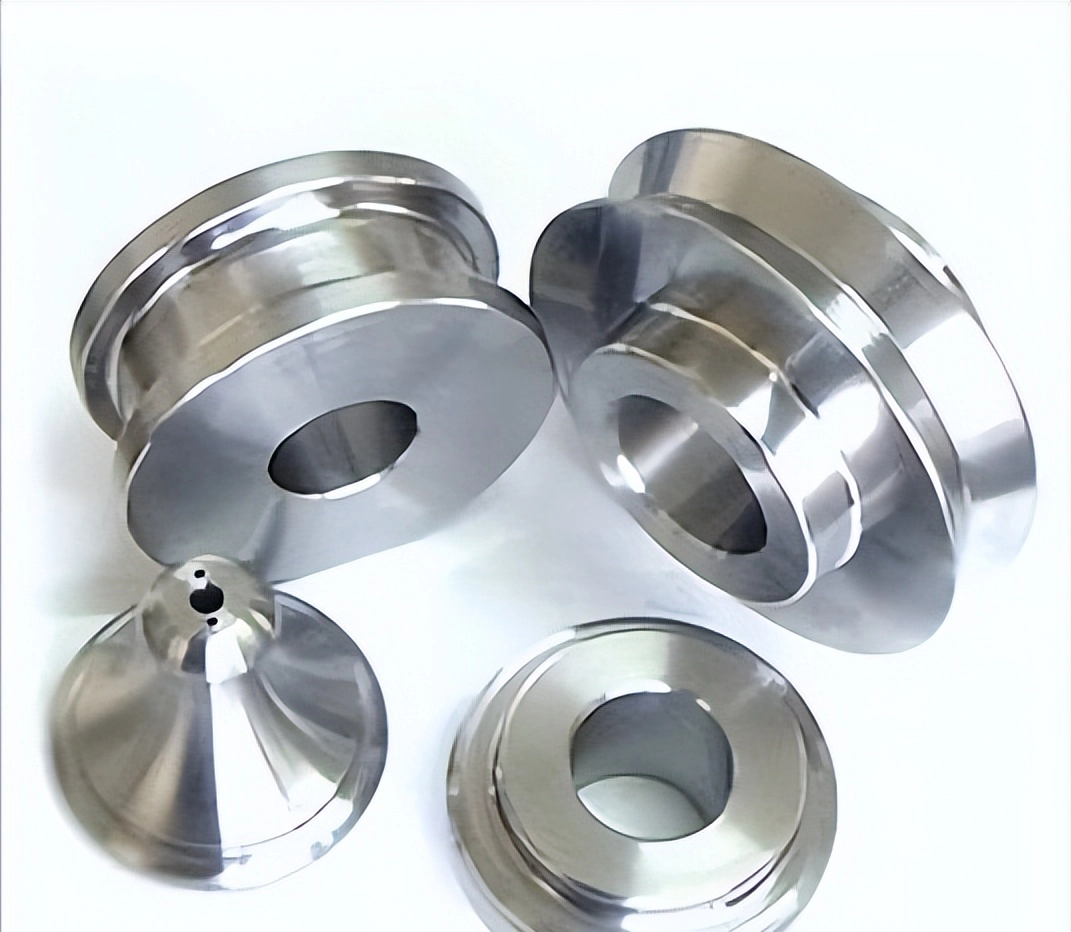

CNC steel

First, I will introduce you to a company with the highest processing accuracy of up to 0.001mm, Co., Ltd.> The machining workshop covers an area of approximately 10,000 square meters, with high automation and very high production efficiency. Except for the blank fixture, all other processing processes can be completed through the CNC machine tool. If used in conjunction with automatic loading and unloading methods, it is a basic component of an unmanned factory.

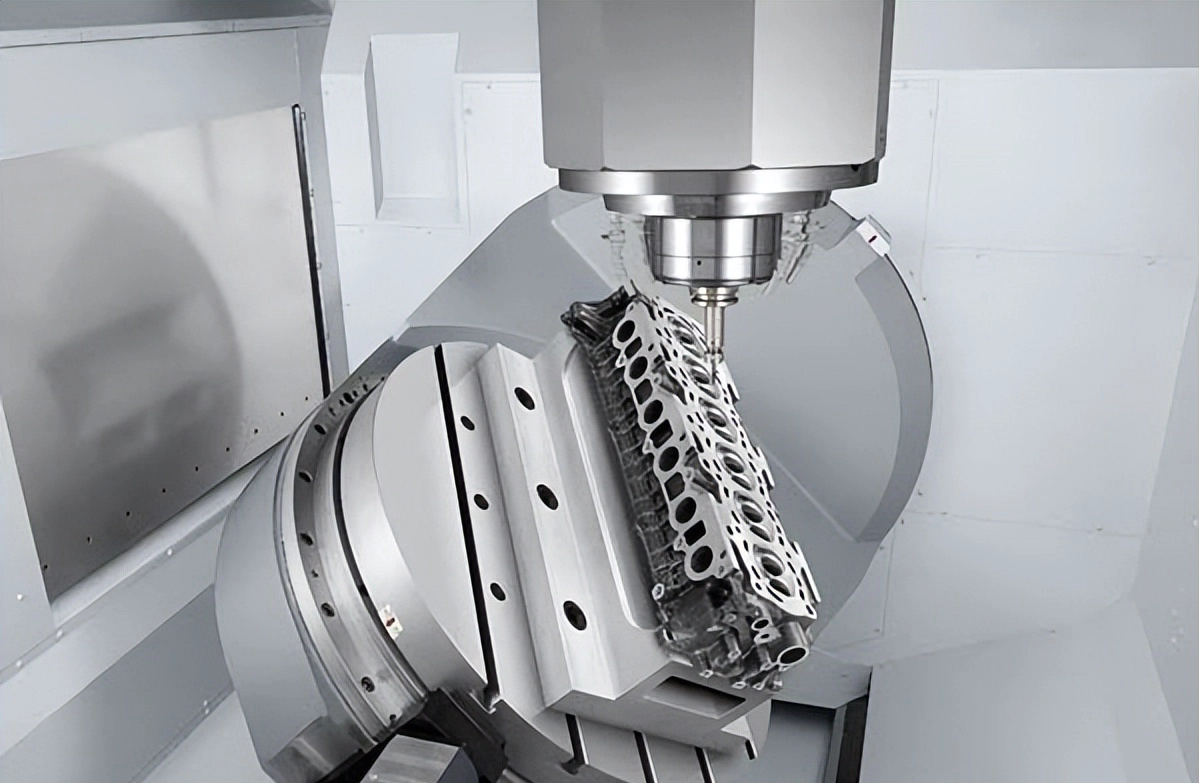

CNC lathe

With the continuous development of high-speed rails, new energy vehicles, 5G, medical equipment, semiconductors, optical components, etc., the accuracy of precision processing is increasingly demanding; it has 27 high-precision CNC machining centers, as well as 90 precise machining support equipment, such as large gantry machining centers, CNC lathes, CNC milling machines, general milling machines, grinders, drilling machines, drill bits, tapping machines, etc., with the highest machining accuracy.

CNC processing reduces operator labor, improves working conditions, eliminates marking, multiple clamping and positioning, inspections and other processes as well as other processes and auxiliary operations, thus effectively improving productivity. Adaptability to CNC processing objects. When replacing processing objects, you only need to reprogram without additional complex adjustments, shortening the production preparation cycle, besides replacing the tool and solving the blank fixture method.

CNC machining has two main functions: one is that it can greatly improve the accuracy of processing, including the accuracy of processing quality and the accuracy of processing time errors; the other is the repeatability of processing quality, which can stabilize the processing quality and maintain the quality of the parts after processing.

Main application industries>

Generally, parts processed by CNC are very accurate, so CNC processed parts are mainly used in the following industries:

Aerospace>

Aerospace requires components with high precision and repeatability, including turbine blades in the engine, tools to make other components, and even combustion chambers used in rocket engines.

Automotive and machine manufacturing>

The automotive industry needs to make high-precision molds for casting parts (such as engine seats) or machining highly resistant parts (such as pistons). The gantry machine can load clay modules and be used during the design phase of the car.

Military Industry>

The military industry uses high-precision components with strict tolerance requirements, including missile components, gun barrels, etc. All machining components in the military industry can benefit from the accuracy and speed of CNC machines.

Medical>

Medical implant devices are often designed to fit the shape of human organs and must be made of advanced alloys. Since no manual machine can produce this shape, a CNC machine becomes necessary.

Energy>

The energy industry covers all engineering fields from cutting-edge technologies such as steam turbines to nuclear fusion. Steam turbines require high-precision turbine blades to maintain balance in the turbine. The shape of the R&D plasma inhibitory cavity in nuclear fusion is very complex and is made of advanced materials that require support for CNC machines.