Ultra-High Strength Steels: A Comprehensive Overview

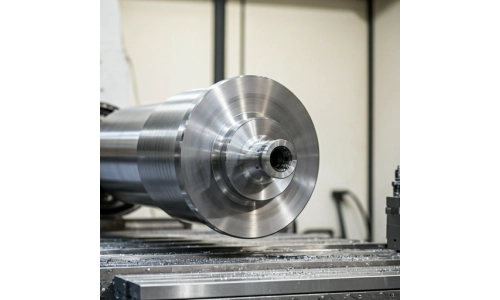

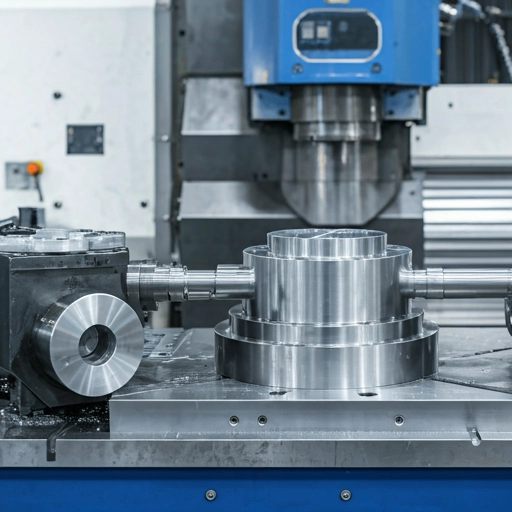

Ultra-high strength steels (UHSS) represent a class of advanced materials engineered to meet the demanding requirements of high-performance structures in cnc machining. Defined by their exceptional yield strength (exceeding 1200 MPa) and tensile strength (surpassing 1400 MPa), these steels offer an unparalleled strength-to-weight ratio, making them crucial for applications where weight reduction is paramount without compromising structural integrity.

Key Characteristics of Ultra-High Strength Steels

Beyond their impressive strength, UHSS exhibit a suite of desirable properties, including:

Exceptional Strength and Hardness: Providing resistance to deformation and wear.

High Toughness: Enabling the material to absorb energy and resist fracture.

Excellent Fatigue Resistance: Ensuring long-term durability under cyclic loading.

Corrosion Resistance: Enhancing performance in harsh environments.

These combined attributes make UHSS indispensable in various demanding sectors.

Leading Examples of Ultra-High Strength Steels

Several companies worldwide have pioneered the development of advanced UHSS, each tailored for specific applications:

Aermet 100 and Aermet 310 (Carpenter Technology)

Developed by Carpenter Technology, Aermet 100 is a high-alloy UHSS renowned for its exceptional performance in critical aerospace components. It has been notably used in the landing gear of advanced fighter aircraft such as the F-22 Raptor and F-18E/F Super Hornet. The successor, Aermet 310, boasts a 10% increase in strength and a fracture toughness (KIc) of 70 MPa compared to Aermet 100, making it suitable for even more demanding cnc machining applications. These steels significantly enhance aircraft structural integrity and reliability.

JFE Steel's High-Strength Steel Series

Japanese steelmaker JFE has introduced a range of high-performance steels catering to diverse needs:

SFGHITEN

This niobium (Nb)-containing high-strength Interstitial Free (IF) steel sheet is primarily used for automotive body panels. IF steels offer excellent formability and tensile strength, contributing to vehicle lightweighting and improved crash safety.

NANOHITEN

With a strength level of 780 MPa, this hot-rolled steel sheet is characterized by its high ductility, hole expansion ratio, excellent flange formability, and stable mechanical properties. It finds extensive use in automotive structural components like reinforcements, arms, and beams.

ERW and HISTORY

Specifically designed for aircraft suspension system components, these 780 MPa high-strength steel tubes offer superior hydroforming capabilities. They are currently being implemented in aircraft suspension arms, improving the performance and reliability of landing gear systems in cnc machining.

SteIR MM (Stelco)

Developed by Stelco, SteIR MM is a high-strength micro-alloyed steel exhibiting exceptional fracture toughness. Testing has shown it to be approximately 22% tougher than conventional steels, making it highly resistant to impact loading and crack propagation. This material has been successfully launched into the market and holds promise for various industrial applications.

Applications Across Industries

The unique properties of UHSS have led to their adoption in a wide array of sectors beyond aerospace:

Automotive Industry

UHSS play a vital role in enhancing vehicle safety and fuel efficiency. They are used in manufacturing structural components like body frames, crash beams, and chassis, contributing to improved crashworthiness and lightweighting in cnc machining.

Heavy Machinery and Construction

In the construction and heavy machinery sectors, UHSS are employed in cranes, excavators, and other heavy equipment to increase load-bearing capacity and enhance structural reliability in demanding environments.

Bridge Construction and Infrastructure

The high strength of UHSS enables the construction of longer-span bridges and taller buildings, offering enhanced structural stability and resilience.

Defense and Military Applications

UHSS are crucial in the defense industry for producing tanks, armored vehicles, and artillery systems, improving protection and mobility in cnc shop.

The Future of Ultra-High Strength Steels

Ongoing research and development efforts are focused on further enhancing the properties and broadening the applications of UHSS:

Enhanced Strength and Toughness

Researchers are continuously striving to push the boundaries of strength and toughness in UHSS to meet the evolving demands of advanced applications, particularly in extreme environments.

Improved Weldability and Formability

Improving the weldability and formability of UHSS is crucial for reducing manufacturing costs and increasing production efficiency, enabling more complex designs and wider adoption in cnc machining.

Superior Corrosion and Fatigue Resistance

Enhancing corrosion and fatigue resistance is a key focus to extend the service life and reliability of UHSS components in challenging operational conditions.

Cost Reduction

Developing more cost-effective production processes and exploring new alloying elements are essential for making UHSS more accessible and expanding their use across various industries.

In conclusion, ultra-high strength steels represent a cornerstone of modern materials engineering, enabling advancements in numerous industries. Continued innovation in this field promises even greater performance and wider applications in the future.