When Making Parts

Q: When should I choose CNC Machining Services?

A: Machined parts have the true properties of the material you select. Our process allows you to get parts machined from blocks of solid plastic and metal in the same time frame.

We mill and turn low quantities of parts very quickly. Typical quantities are one to 200 pieces and manufacturing times are 1 to 3 business days. We offer product developers parts machined from engineering-grade materials that are suitable for functional testing or end-use applications.

CNC machining is more expensive than plastic 3D printing, but it is the most feasible option for metal visual prototypes given the high cost of metal 3D printing and metal casting.

Q: When should I choose 3D printing Services?

A: We can use diverse 3D printing processes to fabricate your parts. More rapid and cost-effective compared with CNC Machining from one piece to large quantities.

3D printing has become a standard technique for developing one-off visual prototypes due to its speed, affordability, and flexibility. Printed parts sometimes lack strength and impact resistance, but this matters little for visual prototypes.

Q: When should I choose Vacuum Casting Services?

A: Vacuum casting is a method for making high quality prototypes or low volumes of parts formed from inexpensive silicone molds. Copies made in this way show great surface detail and fidelity to the original pattern.

Q: When should I use machining versus injection molding?

A: Before making the investment to have injection-mold tooling made or high-volume machining processes, you likely will want to test a part that is as close to the production part as possible. CNC machining is the best option for this situation.

Additionally, engineers often need just one or maybe a few parts for test fixtures, assembly jigs, or assembly fixtures. Machining is the best option here as well, but traditional machine shops often charge a significant non-recurring engineering (NRE) charge for programming and fixturing. This NRE charge often makes getting very small quantities not affordable. The automated CNC machining process eliminates the upfront NRE costs and is able to offer quantities as low as one part at an affordable price and get parts in your hands in as fast as 1 day.

Injection molding is better suited to support larger amounts of samples for functional or market testing, bridge tooling, or low-volume production. If you need parts before a steel tool can be made (typically 6 to 10 weeks with other molders) or your volume requirements don't justify expensive steel production tooling, we can supply production parts to meet your full requirements (up to 10,000+ parts) in 1 to 15 days.

Q: What tolerances can Kesu achieve?

A: There is not a given set of tolerances that fits all processes and materials. In every case, the final tolerances on your part will depend on a number of factors, including but not limited to:

● Part size

● Design geometry

● The number, type and size of features

● Material(s)

● Surface finish

● Manufacturing process

Once your order is confirmed, we will review your design and provide a design for manufacturing review, pointing out any areas where we may not be able to achieve your desired tolerances. It’s helpful if you can specify which areas in your design have critical tolerances that must be met and which can be slightly modified if needed to reduce time and costs involved. Here are some general tolerance guidelines:

● General tolerances for CNC machining in metal and plastic

● Plastic injection molding tolerances

● General tolerance for metal 3D printing is +/- 0.5mm

● Shrinkage rate of +/- 0.15% is to be expected for vacuum casting

All manufacturing and technical specifications need to be clearly specified in the 2D drawings in order to be followed.

Q: How does Kesu ensure the quality of my parts?

A: Once your order is confirmed, we will perform a full Design for Manufacturing (DFM) review to point out any issues that our engineers feel may affect the quality of your parts.

● All incoming materials are inspected and verified with a suite of testing equipment.

● Final inspection reports before shipment.

● We have the ability to share inspection data with you in real-time so we can work together to address any quality issues you may have during production.

Q: What type of surface finishes does Kesu provide?

A: We offer a wide variety of finishing services to achieve almost any look and feel on your parts. We offer treatments for metal, texturing for plastic injection mold tools, painting for metal and plastic, and many more. You can also learn how to specify the surface texture you want in this blog.

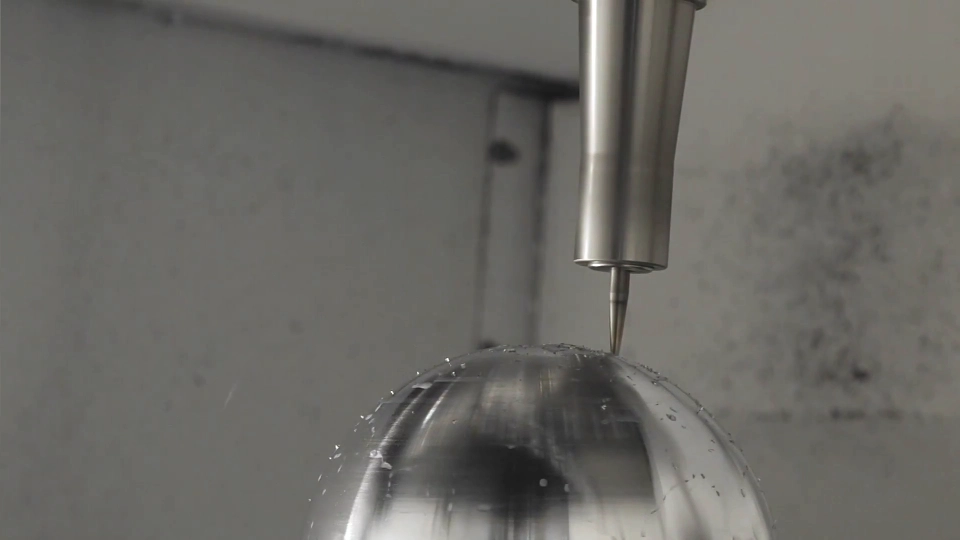

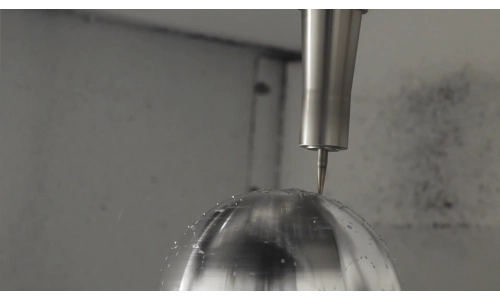

Q: Can Kesu provide optical quality on my plastic parts?

A: Yes. We combine the machining capabilities of the best combined 3-axis, 4-axis or even 5-axis CNC milling machines. We also have adopted the latest diamond machining technology in ultra-precision manufacturing. This is a technique called Single Point Diamond Machining (SPDM or SPDT) that can match the ability of 5-axis micro-milling to produce a range of lens and light guides types of excellent optical quality in an array or freeform pattern. With the rich polishing experience, we can get amazing appearance on both inside and outside of the parts, providing fully support to clear and optical prototype development projects.

Q: What is the mold life for a silicon mold?

A:The service time of the silicone mold is directly related to the complexity of the casting part. Generally, it outputs 12-15 pieces before degradation. If the structure of the part is simple, one mold might be able to cast 20 parts; while if the part requires high quality such as the clear complicated part, one mold can only make 12 or even 10 casting parts.

Q: Why it is important to have a quality standard master?

A: The quality of the casting parts is determined by the quality of master pattern.When the requirement of a client comes to high tolerance, glossy finish or even optically clear parts, the master pattern will be manufactured with CNC machine which is characterized with high specification precision machining and high-quality surface finish.In the meantime, we also can paint parts surface for texture or satin effect to simulate the final mold texture of the product. The silicone molds will copy the details and textures from the original master, so the casting parts will come out the same as the master without any extra finish on the surface.

Q: Is Kesu's CNC machining service in-house?

A: Yes — Kesu Group has more than 80 sets of CNC machining from 3 axis to 5 axis at OUR OWN FACILITIES and in total more than 200 machines for 3D Printing, Vacuum Casting, Sheet Metal machines and injection molding machines that belong to Kesu Group. This gives us a much higher level of production control in comparison to companies that outsource machining.You just get the price from the first manufacturer directly.