Unveiling the Intricacies of CNC POM Parts in Gear Boxes: Understanding and Addressing Simulation Distortion for Optimal Performance

0.00

SKU:CNCS0066

Mpn:CNCM0066

Category:Machining Parts

* The data is open source, not security confidential file from client.

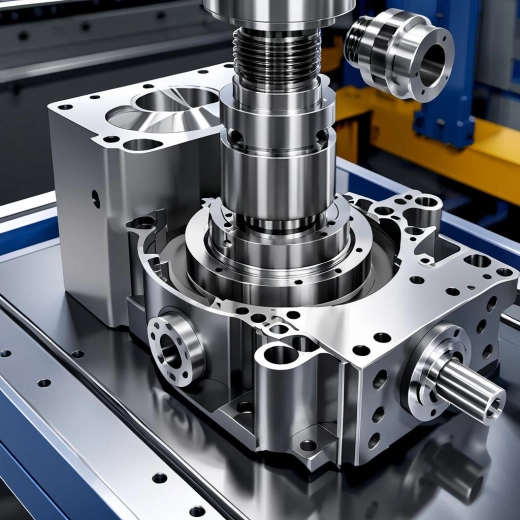

Overview of CNC POM Parts

What are CNC POM Parts?

CNC POM parts, where POM stands for Polyoxymethylene, are components that are precision-machined using Computer Numerical Control (CNC) technology. POM is a high-performance engineering thermoplastic known for its excellent mechanical properties, such as high stiffness, low friction, and good dimensional stability. CNC machining ensures that these parts are fabricated with utmost precision, meeting tight tolerances and complex design requirements. These parts find extensive applications in various industries, with gear boxes being one of the prominent areas of use.

Properties and Advantages of CNC POM Parts

The properties of CNC POM parts make them highly suitable for gear box applications. Their low friction coefficient reduces wear and tear, leading to improved efficiency and longer service life. The high stiffness of POM allows the parts to withstand the forces and loads encountered within a gear box without deforming easily. Additionally, POM has good chemical resistance, enabling it to perform reliably in different operating environments. The ability to be precisely machined using CNC technology further enhances their quality and performance, ensuring a perfect fit and smooth operation within the gear box.

Role of CNC POM Parts in Gear Boxes

Enhancing Gear Box Efficiency

In a gear box, CNC POM parts play a crucial role in enhancing overall efficiency. They are used in various components such as gears, bearings, and bushings. The low friction nature of POM reduces energy losses due to friction, allowing the gear box to transfer power more effectively. This not only improves the performance of the gear box but also leads to energy savings, making it an environmentally friendly choice.

Ensuring Smooth Operation

CNC POM parts contribute to the smooth operation of gear boxes by providing precise and consistent motion. The dimensional accuracy achieved through CNC machining ensures that the parts fit together perfectly, minimizing vibrations and noise. This is particularly important in applications where quiet and smooth operation is essential, such as in automotive transmissions and industrial machinery.

Understanding Simulation Distortion

Causes of Simulation Distortion

Simulation distortion in the context of CNC POM parts in gear boxes can occur due to several factors. One of the main causes is inaccuracies in the simulation model itself. If the material properties of POM are not accurately defined or if the boundary conditions and loading scenarios are not properly represented, it can lead to distorted simulation results. Another factor could be the complexity of the geometry of the CNC POM parts. Intricate shapes and features may not be accurately modeled, resulting in errors in the simulation.

Impact of Simulation Distortion

The impact of simulation distortion can be significant. It can lead to incorrect predictions of the performance of CNC POM parts in gear boxes. For example, if the simulation overestimates the strength of a part, it may lead to the use of an undersized or inadequately designed component, which could fail prematurely. On the other hand, if the simulation underestimates the performance, it may result in over-engineering, leading to increased costs and unnecessary weight.

Addressing Simulation Distortion

To address simulation distortion, it is essential to validate and refine the simulation models. This involves conducting physical tests on CNC POM parts and comparing the results with the simulation predictions. By making adjustments to the model based on the experimental data, the accuracy of the simulation can be improved. Additionally, using advanced simulation software that can handle complex geometries and material behaviors more accurately can also help reduce distortion.

Future Trends and Developments

Advancements in CNC Machining Technology

As CNC machining technology continues to advance, the precision and quality of CNC POM parts will further improve. New machining techniques and tools will enable the fabrication of even more complex and intricate parts with higher accuracy. This will open up new possibilities for the design and performance optimization of gear boxes.

Improved Material Understanding

Research and development efforts are focused on gaining a better understanding of the material properties of POM and how they can be optimized for specific applications. This will lead to the development of new grades of POM with enhanced properties, further improving the performance of CNC POM parts in gear boxes.

Integration of Simulation and Manufacturing

The integration of simulation and manufacturing processes will become more seamless in the future. Real-time feedback from the manufacturing process can be used to update and refine the simulation models, ensuring that the predicted performance of CNC POM parts closely matches the actual performance. This will lead to more efficient and reliable production of gear boxes.