Epoxy board-FR4 used in CNC production

Nylon-PA6 Material used in CNC factory

Polycarbonate-PC Material usage in CNC products

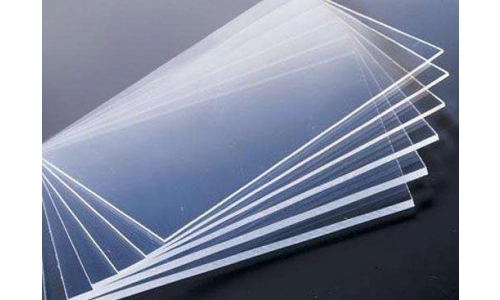

Acrylic material's usage in CNC parts

Saigang-POM material used in cnc manufacturing

T2 Copper Material Introduction Used In CNC projects

ABS engineering plastics Material Detail's Introduction used in CNC production

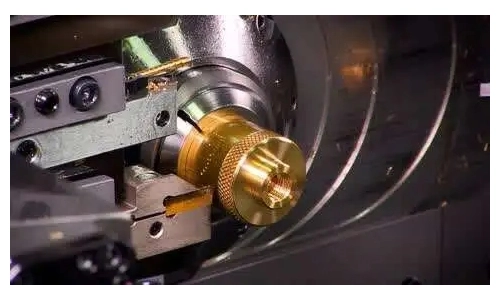

H59 Brass Material in cnc prototyping and production

7075 aluminum alloy Material with cnc milling in cnc factory

6061 aluminum alloy Material for cnc cutting in cnc factory

The importance of Aluminum materials in CNC machining

The unique value of Copper materials and the fitting point of CNC machining

- «

- 2

- »

Impact toughness 0.B.kJ/m2 Friction coefficient DIN53375 0.35

Notched impact toughness 7kJ/m2 Combustion performance UL94 HB

Thermal conductivity 20℃ 0.31w/(mxk) Hot water resistance﹢

Density 1.45g/cm3 Volume resistivity VD0303 ≥1015xcm

Injection speed: medium to fast. Too slow will easily produce ripples, too fast will easily produce jetting and shear overheating.

Also known as polyoxymethylene. The structure is, and the English abbreviation is POM material used in cnc manufacturing. Usually, the polymer obtained by polymerization of formaldehyde has a low degree of polymerization and is easily depolymerized by heat. Around DuPont obtained formaldehyde homopolymer by polymerization of formaldehyde. Polyoxymethylene is easy to crystallize, with a crystallinity of more than 70%. The melting temperature of homopolyoxymethylene is about 180℃.