Aviation Q&A: How Is Bright Titanium Alloy Processed?

Since the discovery of titanium in 1790, mankind has embarked on a century-long arduous exploration to obtain its extraordinary properties. Humans first produced titanium metal in 1910, but the application of titanium alloys has gone through an arduous and long process. It was not until 1951, 40 years later, that industrial production was finally achieved.

my country began the development and application of titanium alloys in the 1960s.

TitaniumTi

Titanium alloy has the characteristics of high specific strength, corrosion resistance, high temperature resistance and fatigue resistance. Titanium alloy of the same size weighs only 60% of steel, but is stronger than alloy steel. Due to its good properties, titanium alloys are often used in medical fields, such as artificial joints, bone fixation devices, dentures, etc...

"Space Metal"

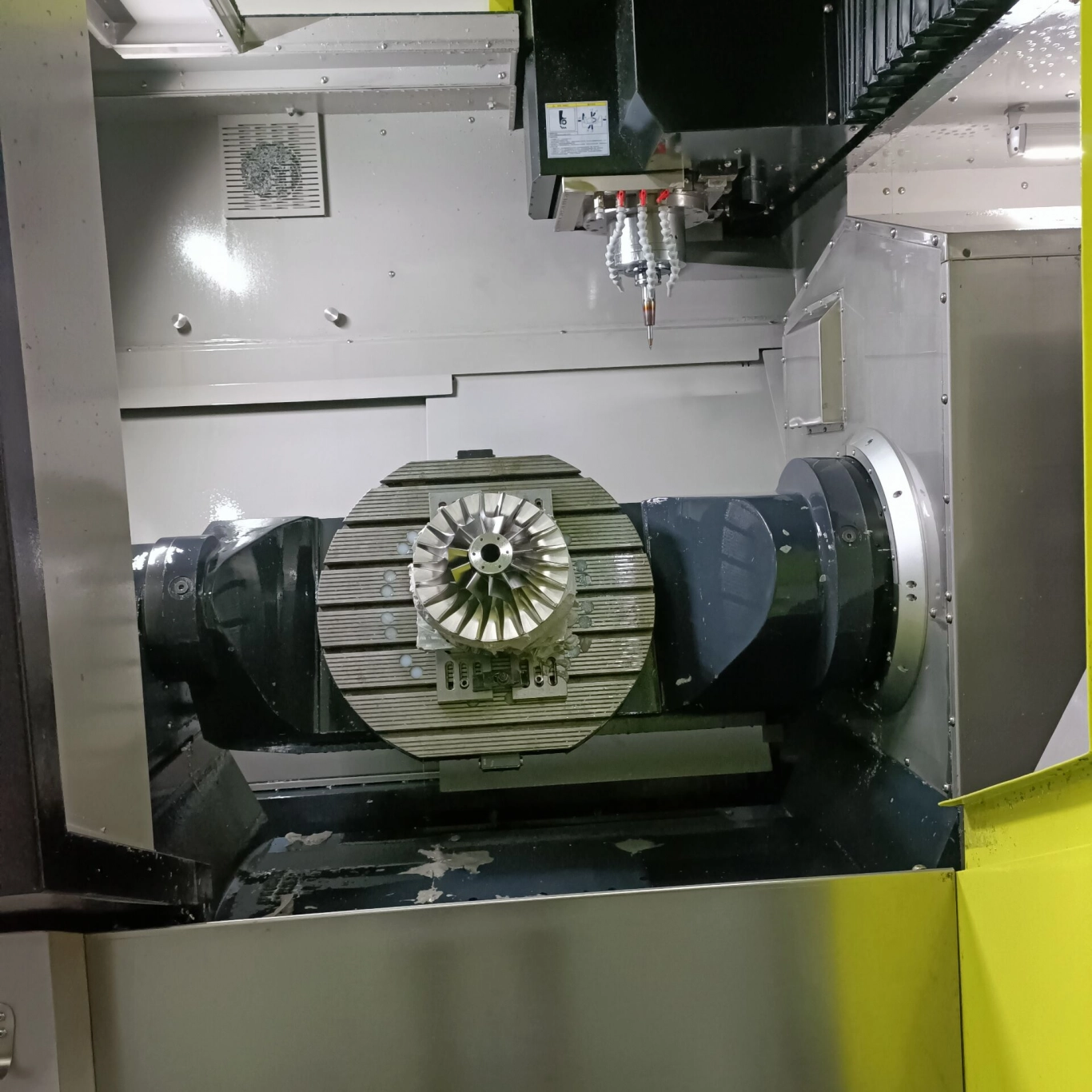

Titanium alloys are widely used in aircraft structural parts and heat-resistant parts. It is one of the main structural materials of contemporary aircraft and engines and is known as "space metal".

But titanium alloy is like a fierce horse. Its ferocity must be tamed in order to achieve the goal of traveling thousands of miles a day. So how can we “tame” titanium alloys?

Titanium alloy has poor thermal conductivity, high hardness, and is easy to rebound. The difference in thermal conductivity is reflected in the large amount of heat generated by friction during processing. If it is made of other metals, it will be quickly transmitted to the whole, such as the pots we usually use.

However, titanium alloys have poor thermal conductivity and will continue to accumulate heat, making the titanium alloy sticky, causing the knives to become brittle due to heat, causing severe wear and even damage to the knives, just like cutting jellybeans with scissors. knife.

Titanium alloy has high hardness, and aluminum alloy materials also used on aircraft are relatively simple to process: it takes 1 meter of titanium alloy material to process 25 meters of aluminum alloy material, which is more economical, but the strength of aluminum alloy is difficult to meet the requirements. , so although titanium alloy processing is difficult, it is very necessary. Moreover, titanium alloy rebounds severely, affecting the machining accuracy of parts. Especially for parts with thin walls and complex shapes, processing is more difficult.

As titanium alloy processing technology becomes increasingly mature, processing equipment, cutting tools, etc. are constantly improved and improved. Stable processing of ultra-large structural parts and precision and complex parts can now be achieved. The processing accuracy can be stabilized at 0.2 mm, and can reach 0.1 mm in some areas. It is the thickness of a piece of A4 paper, more accurate, and the processing efficiency is also significantly improved.

Powerful milling, shallow cutting high-speed milling, etc. make the processing of titanium alloy parts faster and more stable. We have developed superplastic forming methods for titanium alloy sheet processing, compressed air stirring for chemical milling, low current fast welding for welding and other methods to tame these fierce horses.

Only titanium alloy Maxima can be used by us in the manufacturing of aviation equipment. I believe that with the continuous research and exploration of the vast number of scientific and technological workers in the aviation industry, our understanding of titanium alloys will gradually deepen. We will be able to tame the thousand-mile horse of titanium alloy. With more means, we will make greater contributions to our country’s aviation industry!